Torsion buffering driver for passenger car

A technology for passenger cars and transmissions, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve problems such as heating up of dual-clutch modules, waste of kinetic energy in high-speed rotation, and deterioration of acceleration effects, etc., to reduce work temperature, reduce fuel consumption, and reduce the effect of sliding grinding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

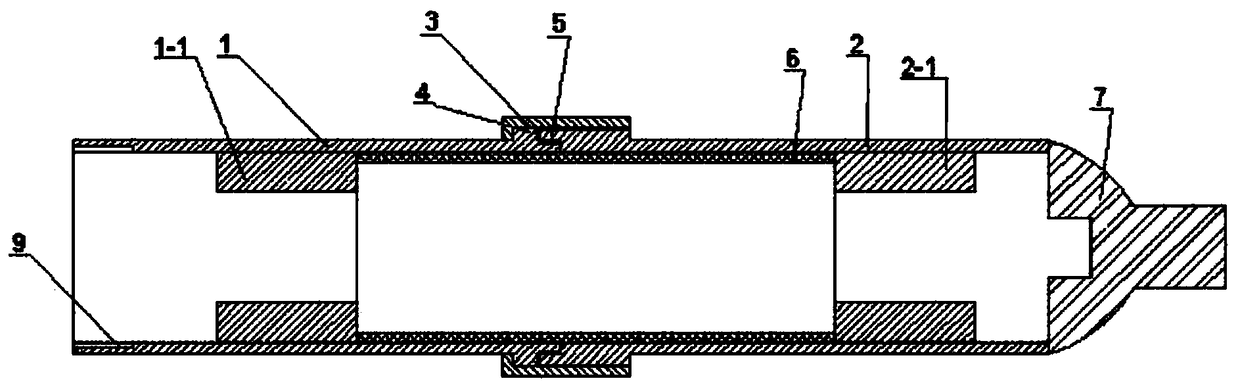

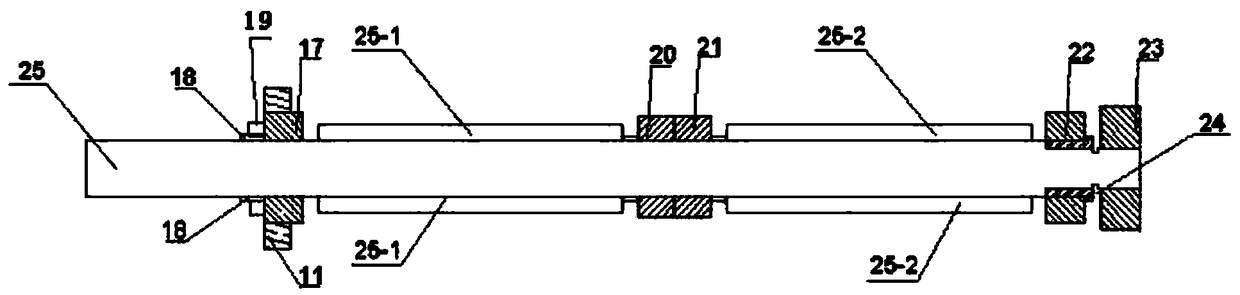

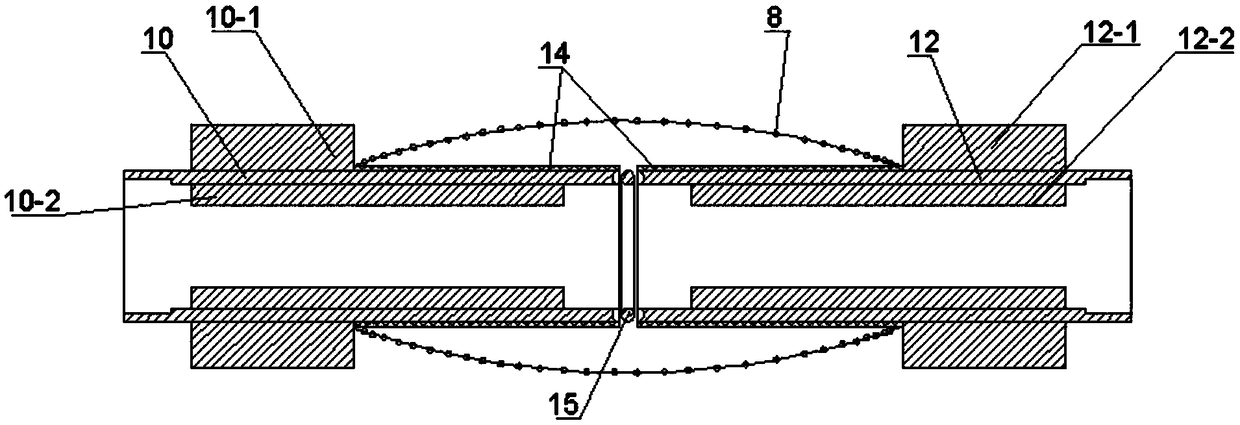

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 as well as Figure 5 As shown, the structure of the torsion buffer transmission for passenger cars includes an input shaft 25, the left side of the input shaft 25 is symmetrically arranged with an input shaft left boss 25-1, and the right side of the input shaft 25 is arranged with an input shaft right convex platform symmetrically up and down. Platform 25-2, the left side of input shaft left boss 25-1 is provided with the first roller bearing 17 (structure such as Figure 8 shown); between the input shaft left boss 25-1 and the input shaft right boss 25-2, a second roller bearing 20 is arranged in turn (structure such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com