Cone-shaped C-shaped single-valve-plate-type electric four-way valve

A technology of four-way valve and single valve, which is applied in the field of cone C-shaped single-valve electric four-way valve, which can solve the problems of increased steering torque, pressure suppression when the flow is cut off, increased maintenance volume, etc., and achieves friction reduction , Eliminate impact, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

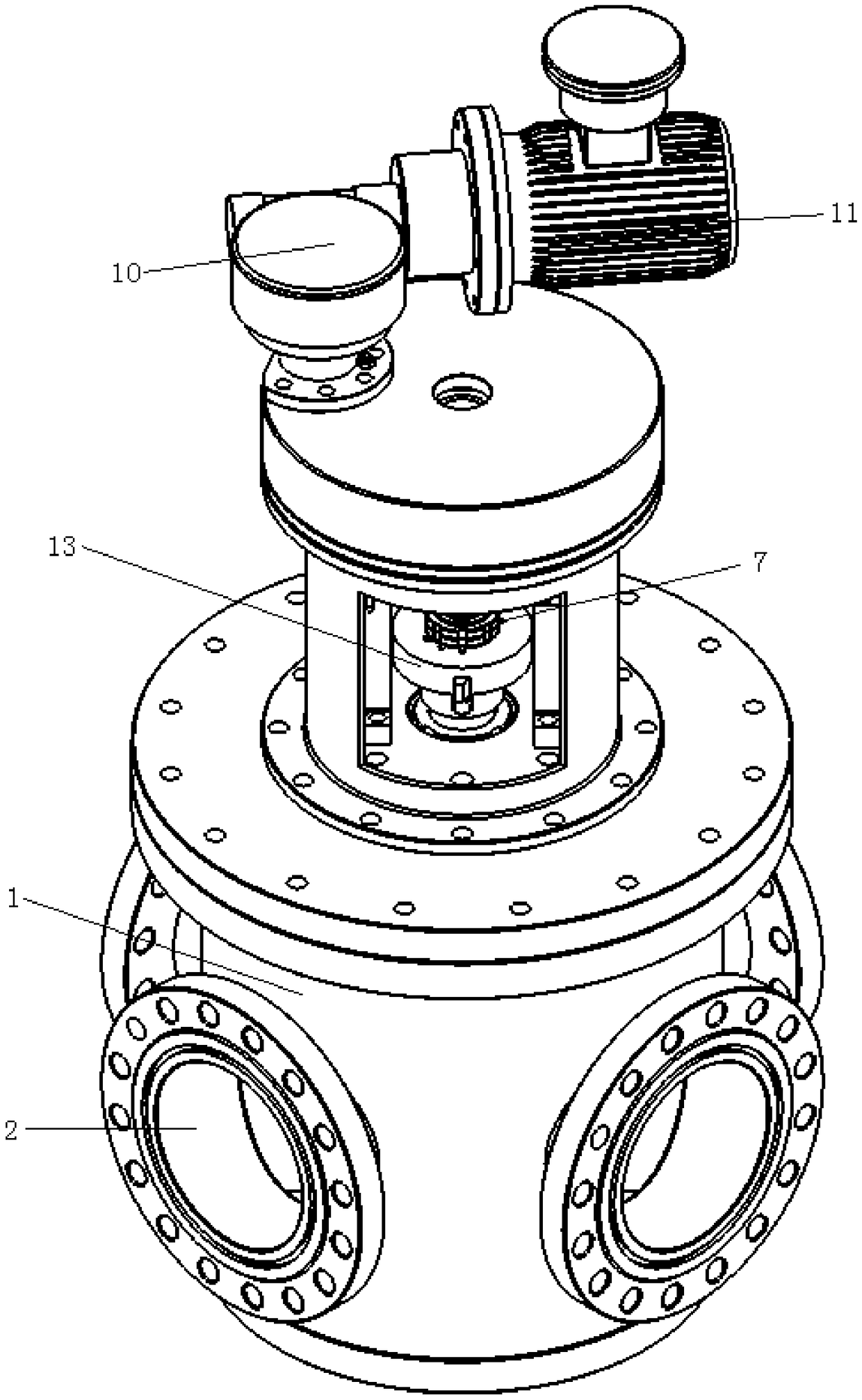

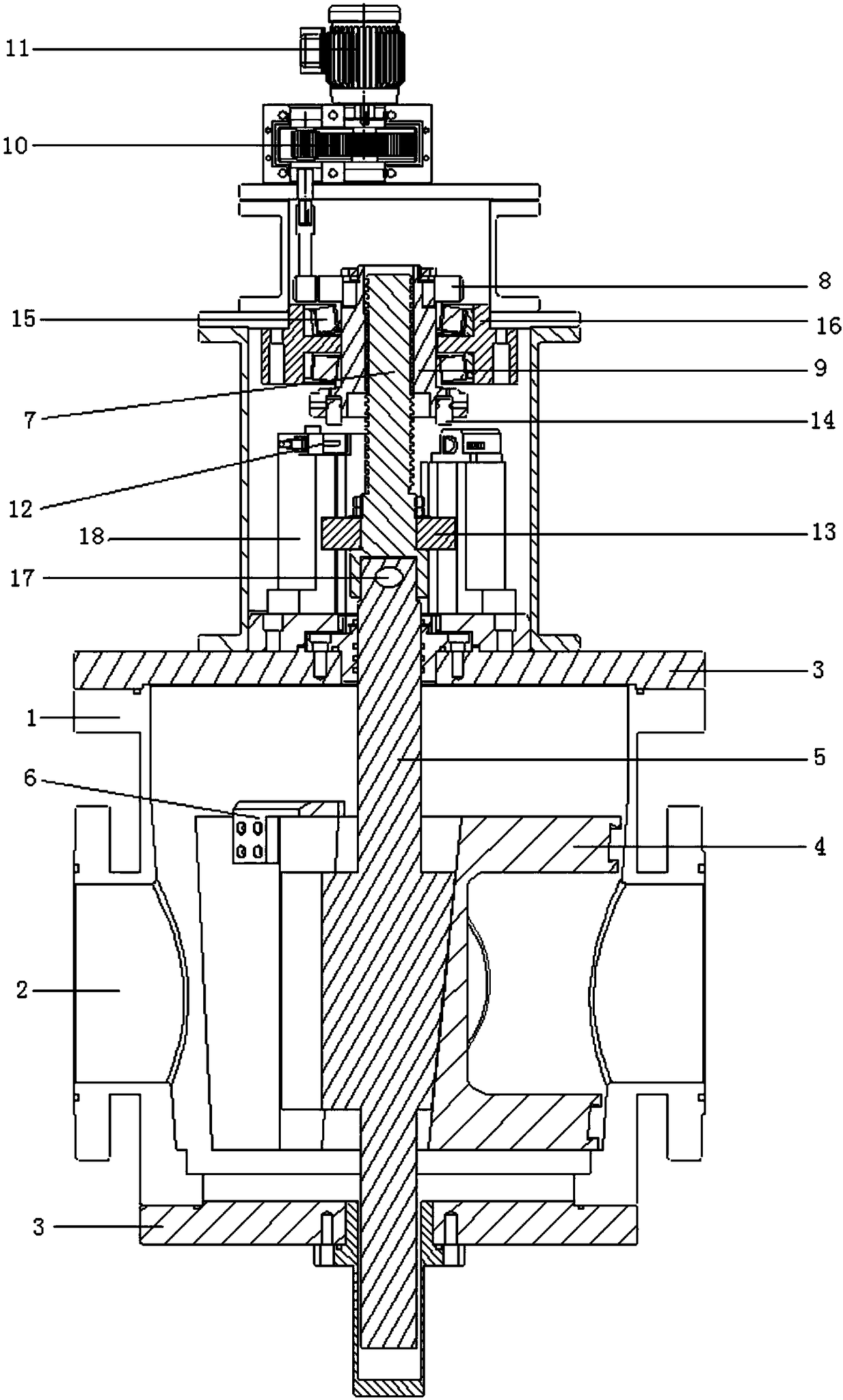

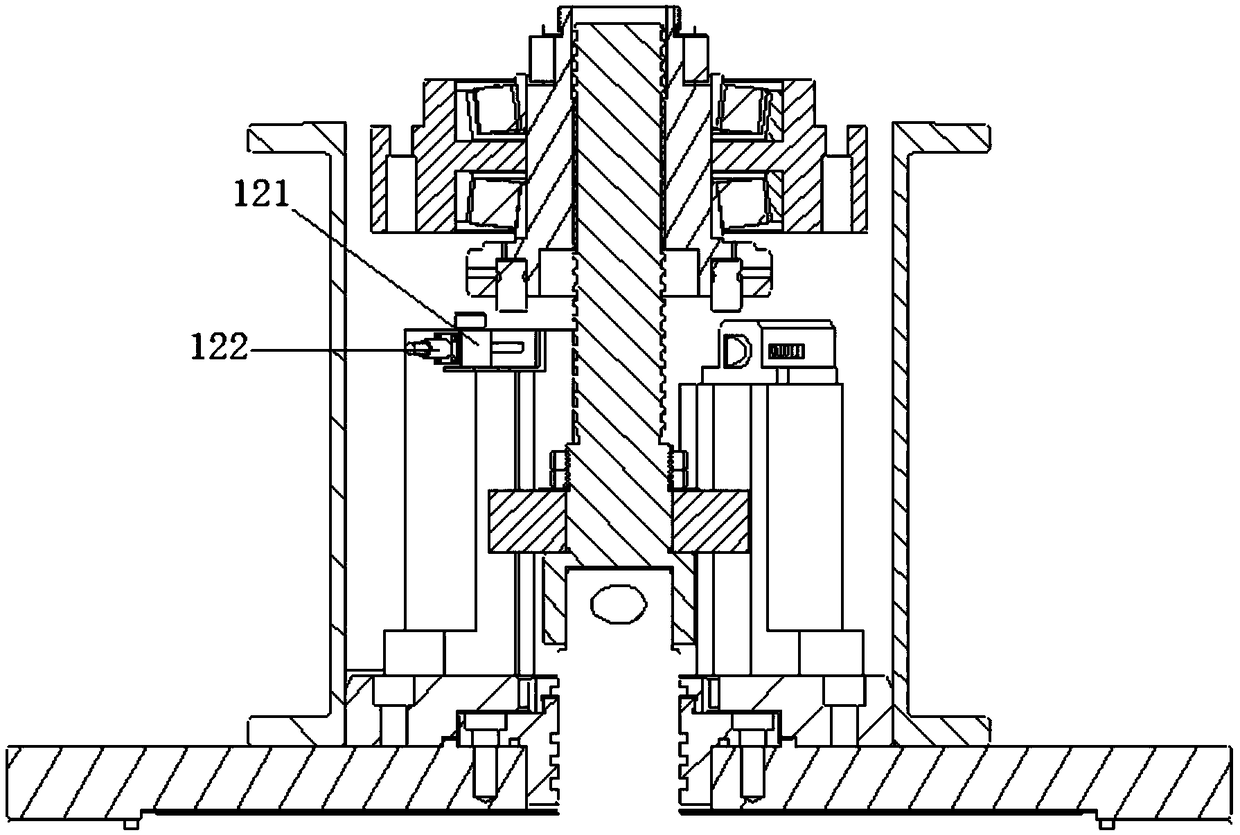

[0032] A conical C-shaped single-valve electric four-way valve, refer to Figure 1-5 , including a tapered cylindrical valve seat 1, the valve seat 1 protrudes from the same horizontal surface and four perpendicular liquid pipes 2, the upper and lower ends of the valve seat 1 are provided with flanges 3 for sealing, the valve seat 1 The inner cavity is provided with a spool 4 and a spool shaft 5 connected with the spool 4, the upper and lower ends of the spool shaft 5 pass through the center of the flange 3, a positioning copper sleeve is provided between the spool shaft 5 and the flange 3, and Seal the connection. The upper end of the spool shaft 5 is connected to control its transmission control mechanism for up and down and rotation, refer to Figure 6-11 , the spool 4 is provided with a C-shaped liquid port, the spool 4 is provided with a vertical card slot on the opposite side of the C-shaped liquid port, and the spool shaft 5 is provided with a card block matching the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com