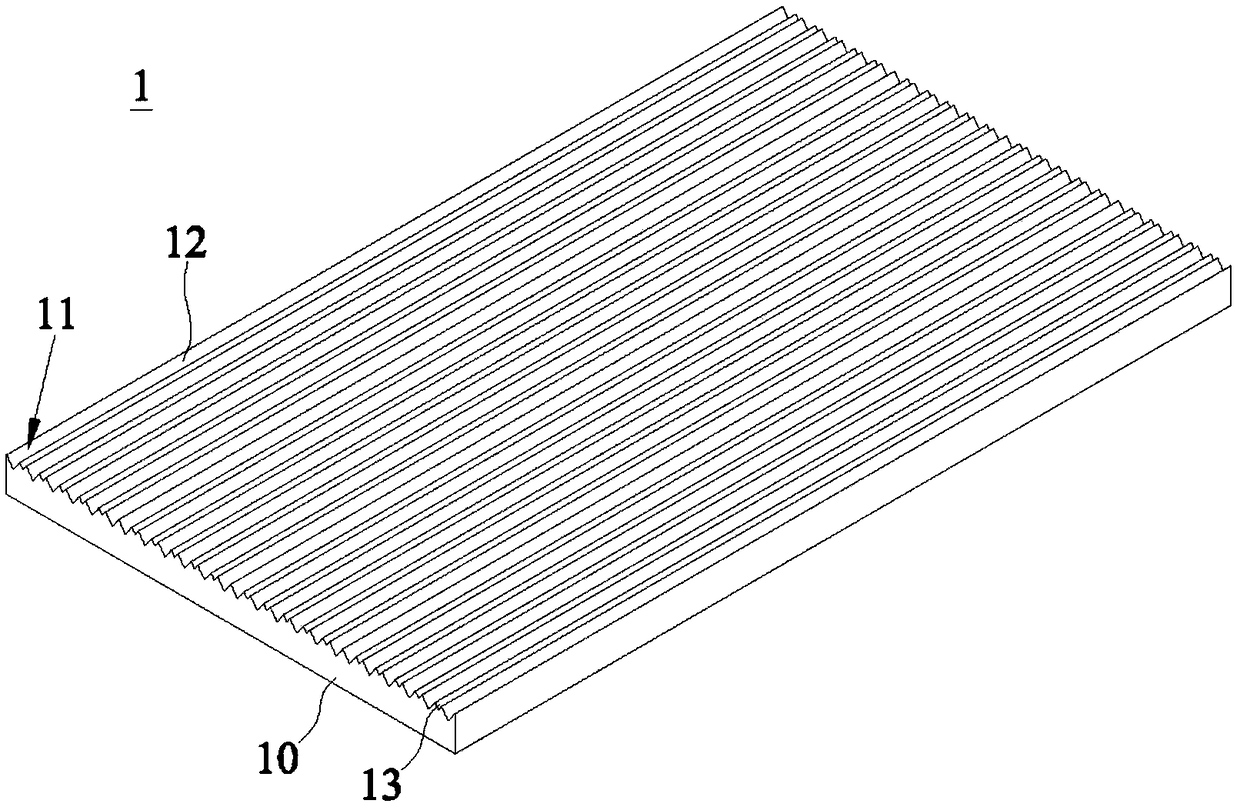

Light guide plate with high outgoing light uniformity, and manufacturing method for light guide plate

A manufacturing method and technology for a light guide plate, applied in the directions of light guide, optics, optical components, etc., can solve the problems of poor light uniformity and low production speed of the light guide plate, so as to ensure the uniformity of the overall light output, solve difficult processing, and prevent bright light. dark uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

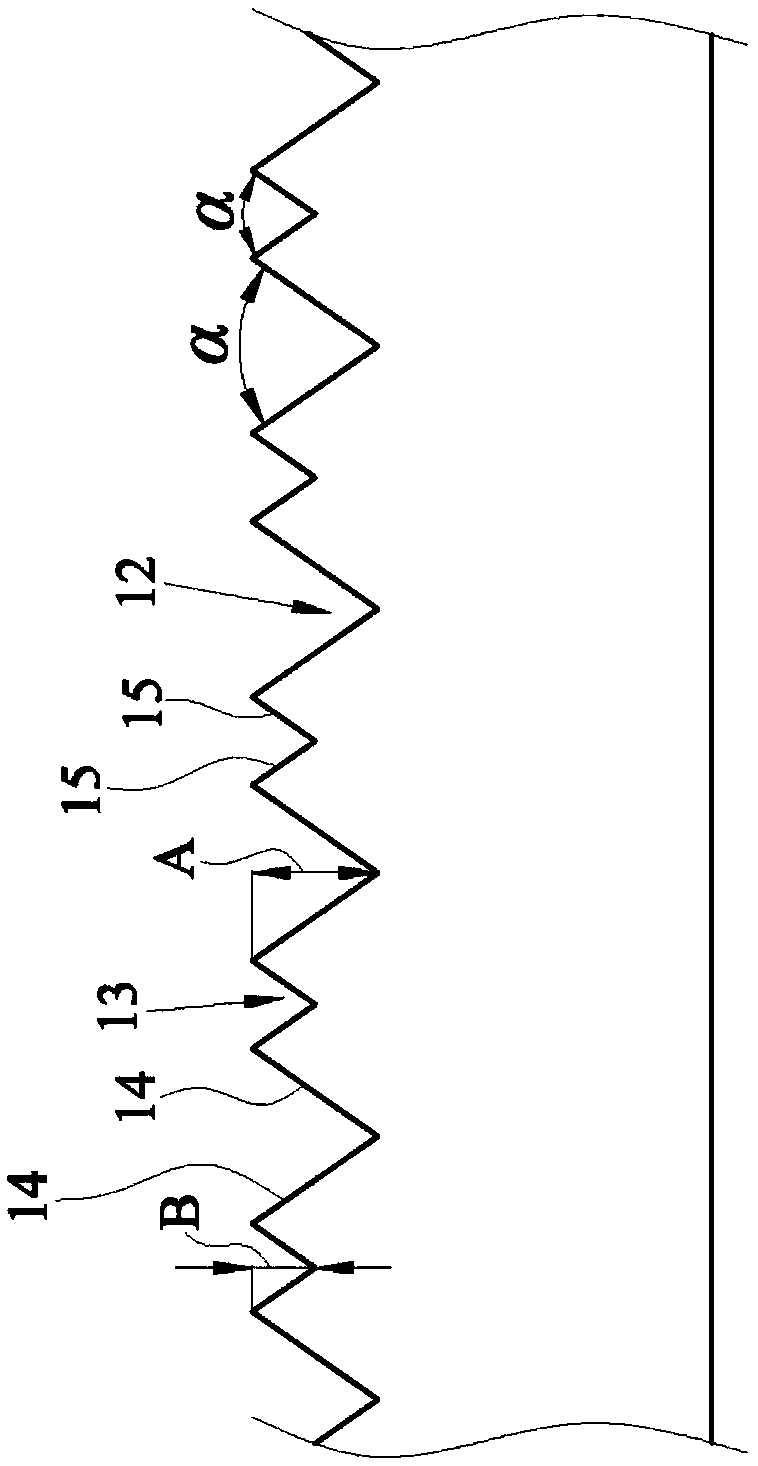

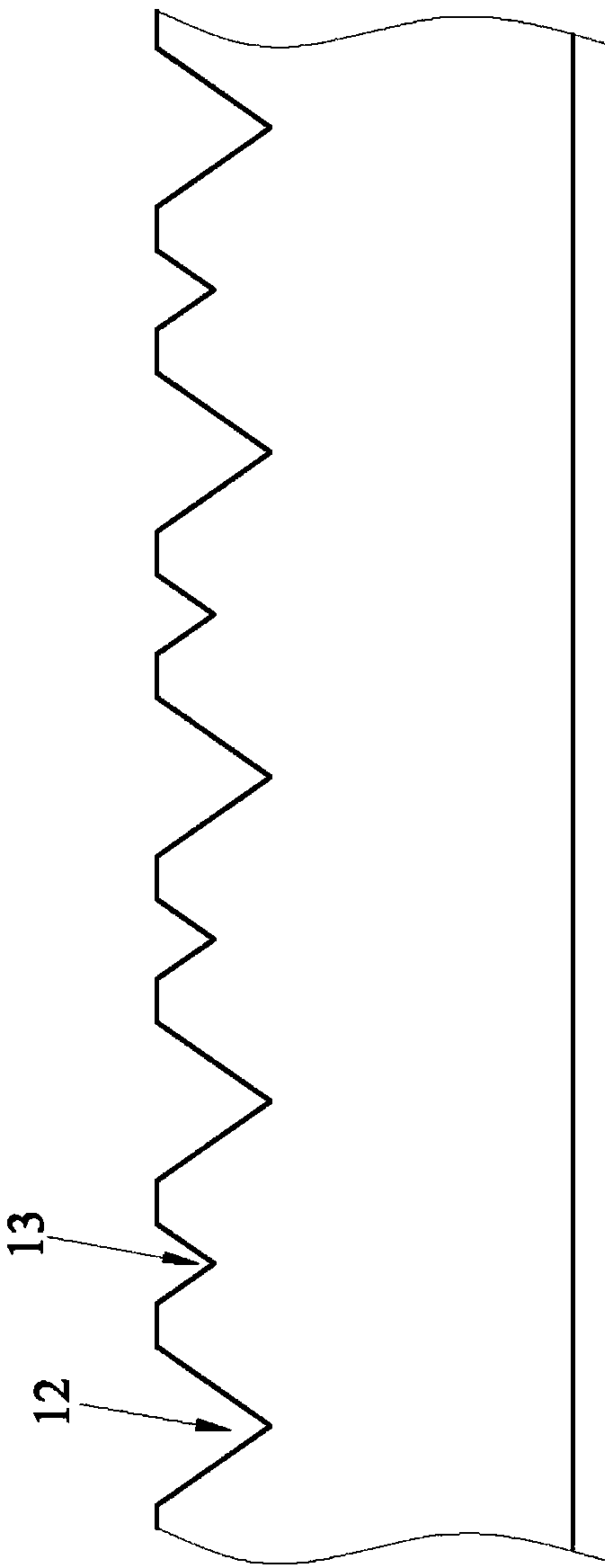

[0043] Nowadays, in order to improve the uniformity of light output from the light guide plate, a plurality of groove structures with the same depth are usually arranged on the surface of the light guide plate, so that the brightness and uniformity of light output from the light guide plate can be improved by using the groove structure. However, the inventors have found through actual operation and experiments that although the groove structure can increase the brightness of light output, the groove structure will cause adverse effects such as uneven distribution of light and dark or excessive brightness in some areas of the light output surface. The reason for the influence is the groove depth. When the depth of the groove structure is shallow, excessive light-splitting staggered lines will be generated in the area adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com