Packaging structure for LED

A technology of packaging structure and packaging components, applied in the field of LED plant lighting and horticultural lighting, can solve the problem of uneven LED light output, achieve uniform illumination of plants, convenient and quick assembly, and improve the uniformity of light output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

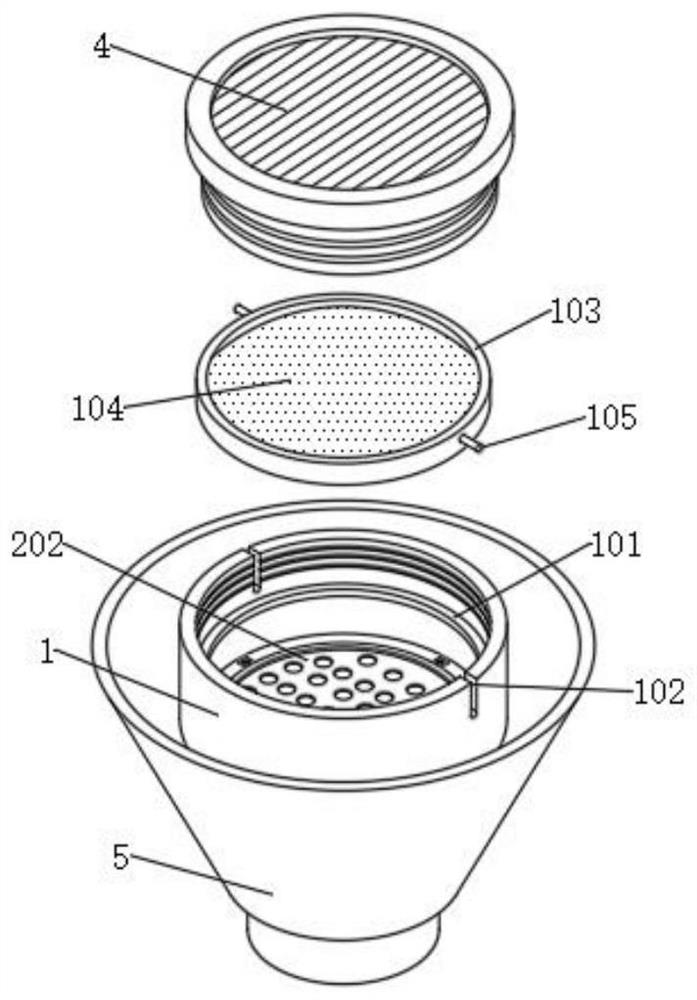

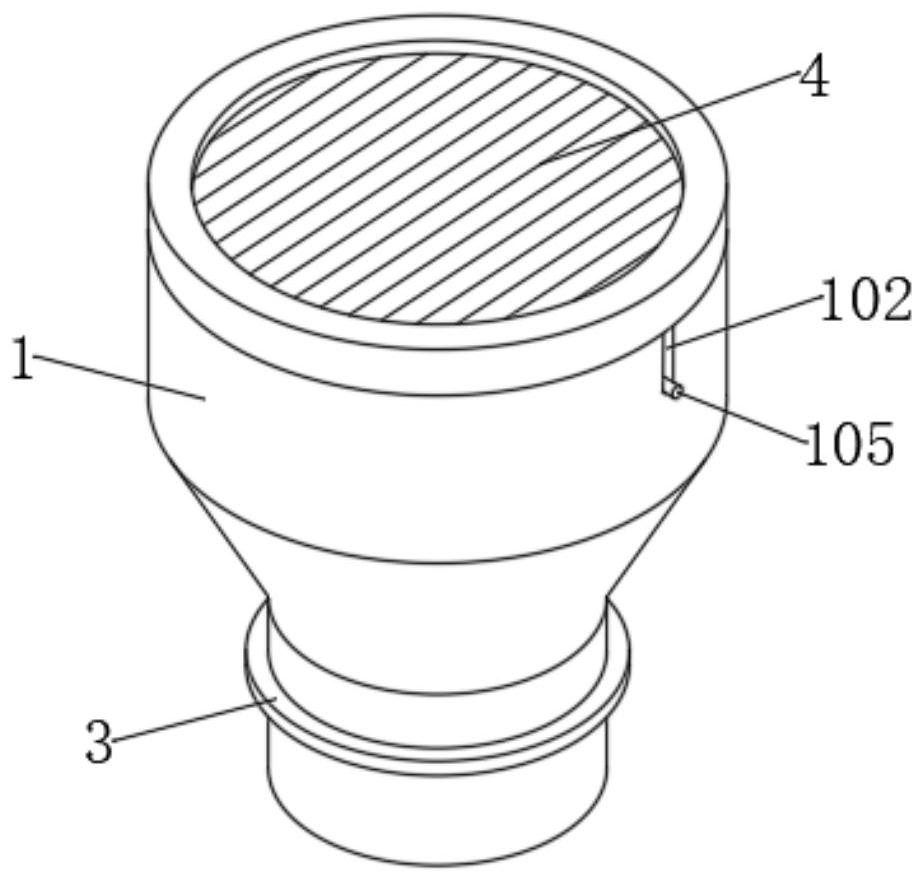

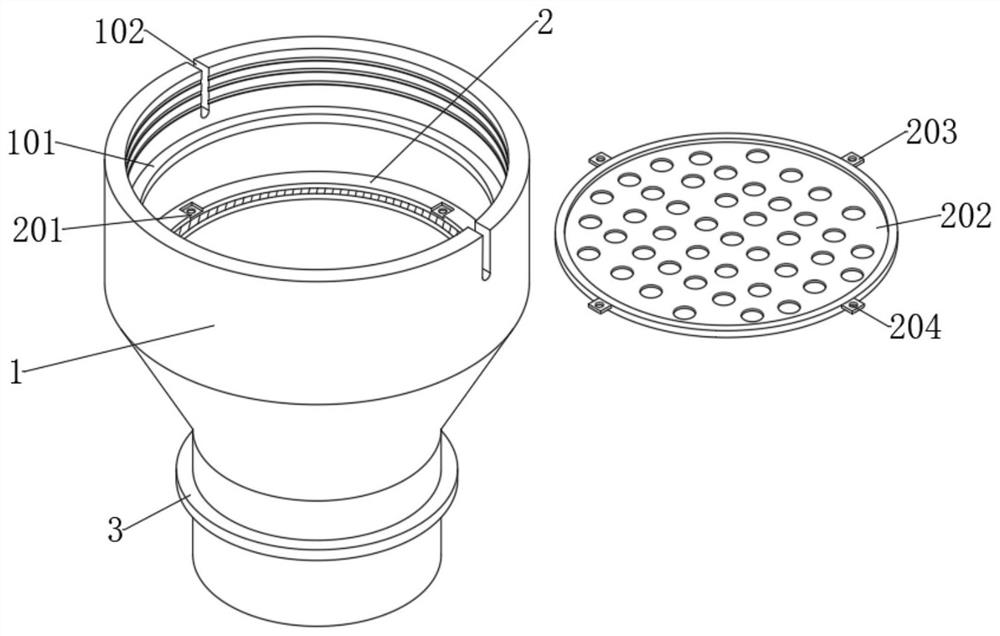

[0050] see figure 1 and figure 2 , an embodiment provided by the present invention: a packaging structure for LED, comprising a lampshade main body 1, an object board 2 and a convex lens packaging assembly, the inner surface of the lampshade main body 1 is installed with a retaining ring 101, the lampshade main body 1 is installed The interior of 1 is provided with an object storage board 2, and the object storage board 2 is located below the retaining ring 101, and the convex lens packaging component is arranged in the lampshade main body 1 and is clamped with the lampshade main body 1.

[0051] The beneficial effects of the above scheme are: the present invention installs the object board 2 and the convex lens package assembly in the lampshade main body 1, so that the convex lens in the convex lens package assembly is installed in the lampshade main body, and the external structure of the LED is improved by adding a convex lens. The convex lens emits light, improves the ph...

Embodiment 2

[0053] see figure 1 and figure 2 , the convex lens package assembly includes: a case 103, a convex lens 104 and a blocking rod 105, the top of the blocking ring 101 is placed with a case 103, the inner surface of the case 103 is fitted with a convex lens 104, the watch A symmetrically arranged blocking rod 105 is installed on the outer surface of the shell 103 , a symmetrically arranged slot 102 is arranged through the outer surface of the lampshade main body 1 , and the socket 102 is in the shape of a long strip. The blocking rod 105 and the slot 102 The cross section of the storage board 2 is "L"-shaped, and the blocking rod 105 on the outer surface of the watch case 103 is moved down along the slot 102 until the blocking rod 105 can be fitted with the bottom end of the socket 102. , at this time, the bottom surface of the watch case 103 will be attached to the retaining ring 101 to play a certain limiting and fixing role, and then the convex lens 104 in the watch case 103...

Embodiment 3

[0059] On the basis of any of Examples 1-2, see Figure 5-12 ,Also includes:

[0060] The outer surface of the lampshade main body 1 is symmetrically provided with two sets of connecting grooves 6, and the connecting grooves 6 are provided with a driving motor 1 7 and a driving threaded rod 8. The output shaft of the driving motor 1 7 is connected with the driving threaded rod. The lower end of the rod 8 is fixedly connected, and a protective cleaning device 9 is slidably sleeved on the outer surface of the lampshade main body 1 .

[0061] The protective cleaning device 9 includes: a protective assembly 10, a dustproof casing 11, a cleaning assembly 12 and a threaded sleeve 13, the dustproof casing 11 is slidably sleeved on the outer surface of the lampshade main body 1, and the top of the dustproof casing 11 The protective assembly 10 is provided, the inner wall of the dust-proof housing 11 close to the connecting groove 6 is fixedly connected with the threaded sleeve 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com