COB light source capable of uniformly emitting light

A light source, uniform technology, applied in the field of COB light sources with uniform light output, can solve the problems of not meeting the application requirements of non-circular light spots such as rectangles, different lighting conditions, and inhomogeneous light output directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

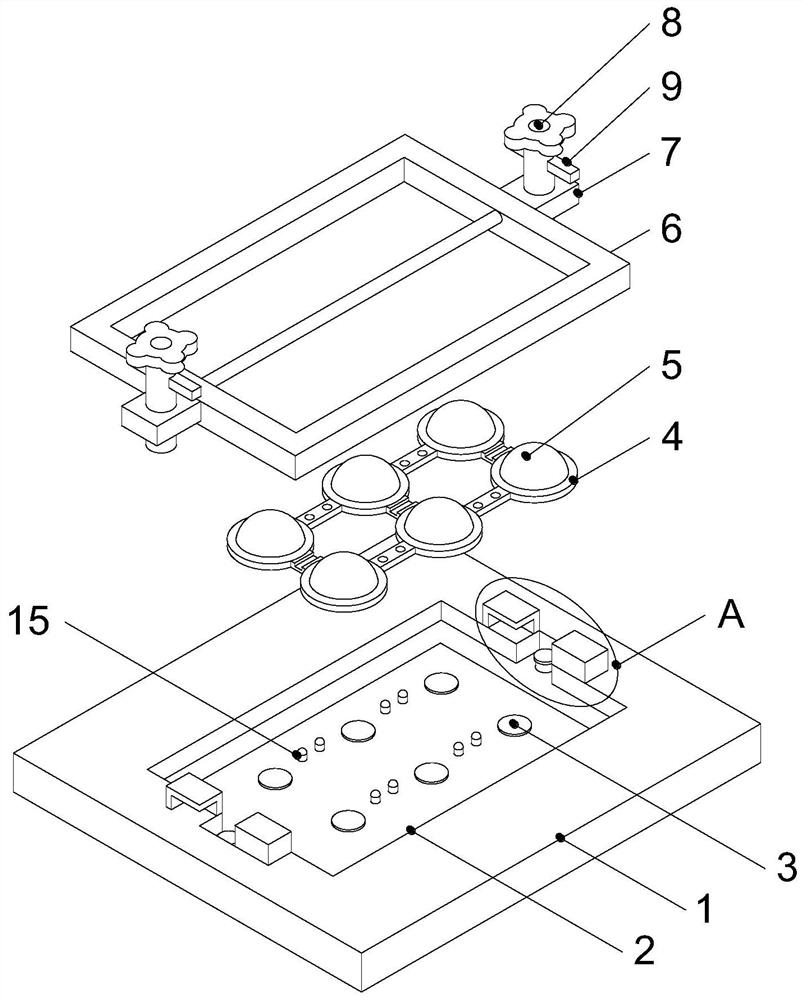

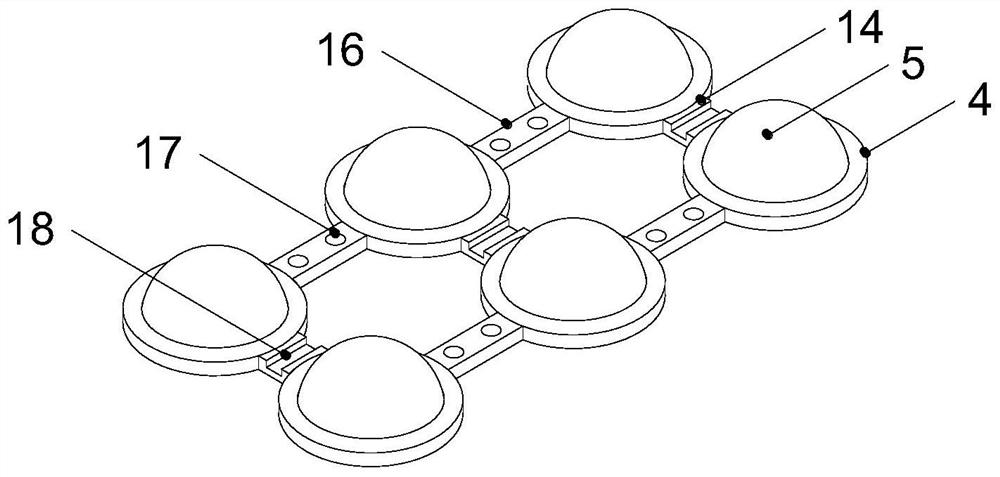

[0023] Example: such as Figure 1-4 As shown, a COB light source with uniform light output in the present invention includes a base 1 and a circuit board. The base 1 is provided with a circuit board groove 2, and the circuit board is installed in the circuit board groove 2. Multiple COB light sources are installed on the circuit board. Block 3, and the surface of COB light source block 3 is provided with lens 5 respectively, the surface of lens 5 is installed on the mounting sleeve 4, and the mounting sleeve 4 is respectively connected by connection block 14 and connection block 2 16, connection block 14 They are respectively arranged between two horizontal installation sleeves 4, and the connecting block 2 16 is arranged between two vertical installation sleeves 4, and an installation frame 6 is provided directly above the installation sleeve 4, and the installation frame 6 and the circuit board groove 2 are matched in size, the mounting frame 6 is a rectangular structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com