Bullet marking and sorting device

A sorting device and marking technology, applied in the direction of sorting, etc., can solve the problems of low automation of inventory and management, achieve the effect of safe and automatic storage and management, and avoid classification errors or disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

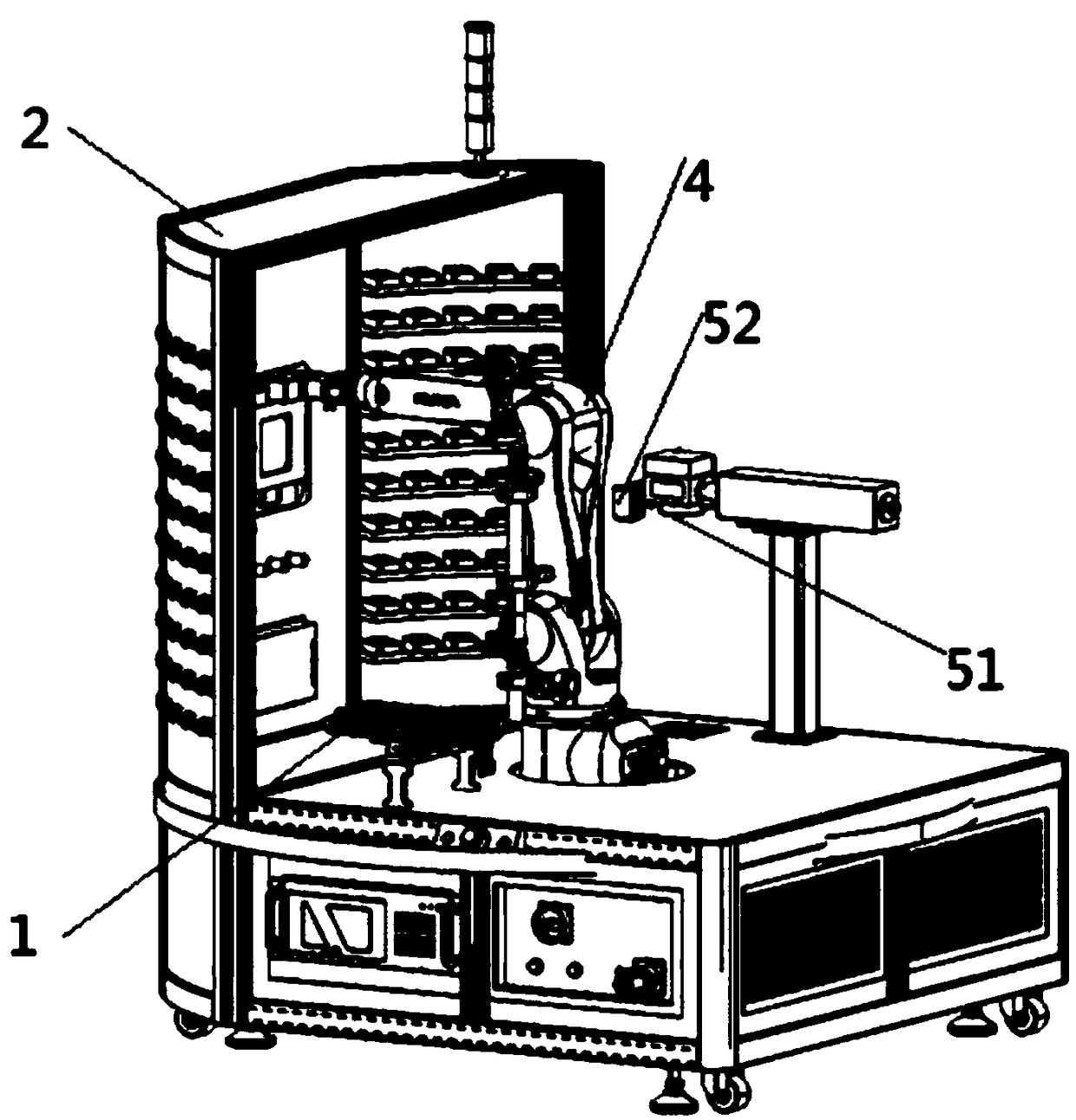

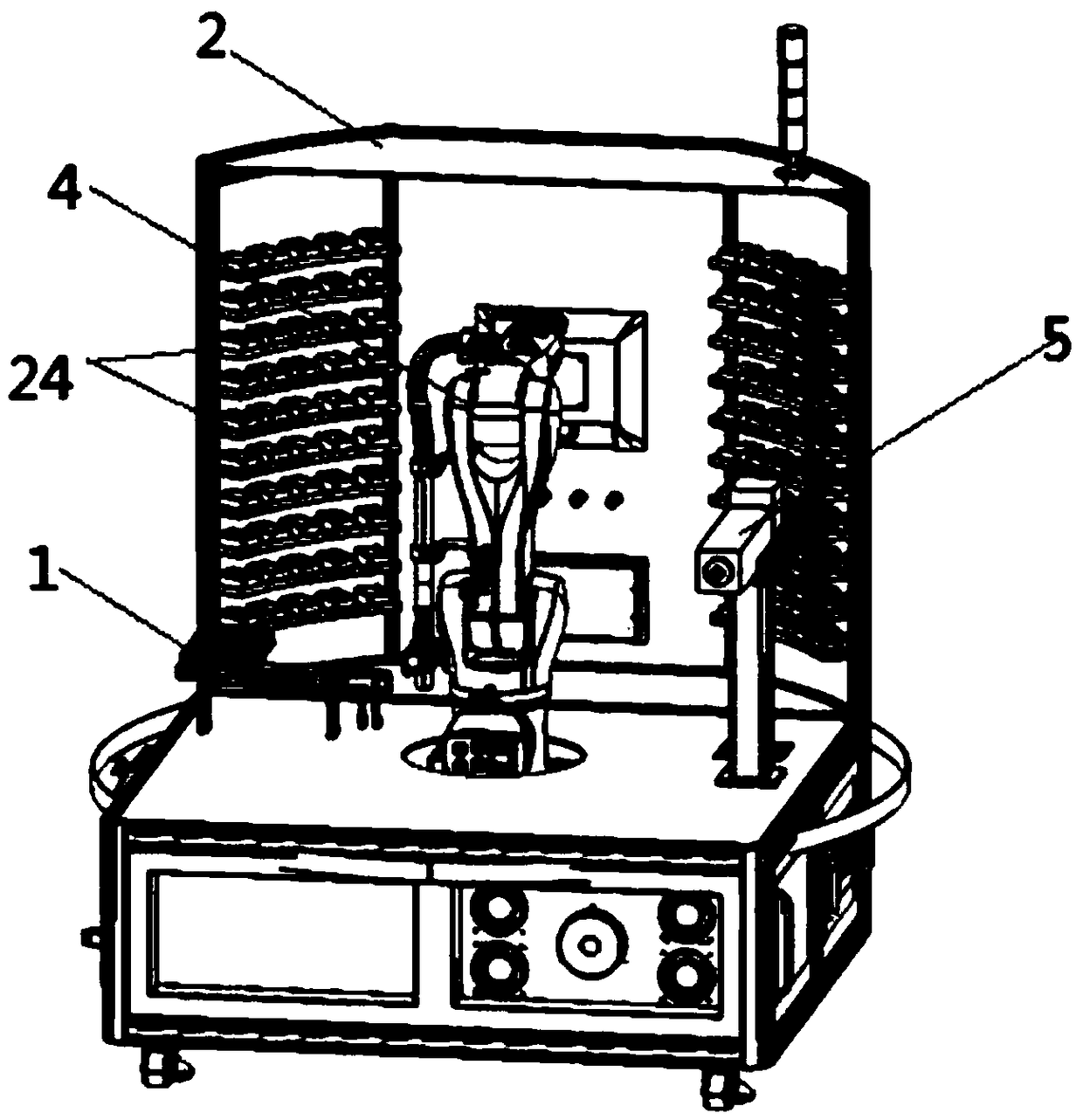

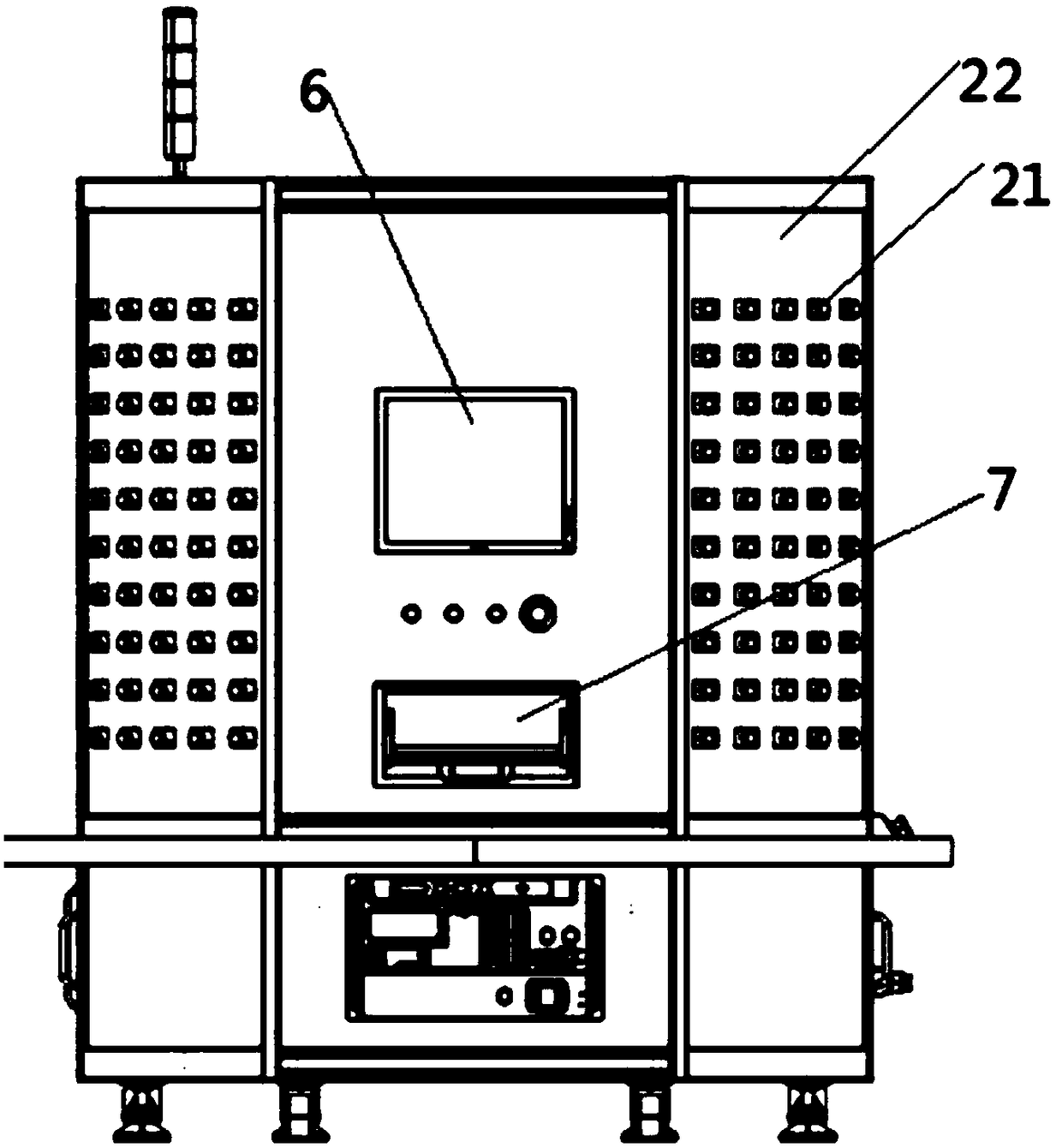

[0041] Such as Figure 1-2 As shown, the present invention discloses a bullet marking and sorting device, which mainly includes a feeding mechanism 1, a storage mechanism 2, a marking and sorting mechanism, an input and output mechanism and a control mechanism (not shown in the figure), Wherein the marking and sorting mechanism includes an execution unit 4 and a marking recognition unit 5, such as image 3 As shown, the input and output mechanism in this embodiment includes a display screen 6 and a keyboard 7, wherein the display screen 6 is arranged on the material storage rack 22, and is arranged towards the outside of the material storage rack 22, and the keyboard 7 is foldable and stored in the storage material When it needs to be used, it can be opened from the material storage rack 22 by the handle, and it can be stored in the material storage rack 22 when not in use. The input and output mechanism, the executive mechanism and the mark recognition unit are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com