Processing method and processing device for butterfly optical cable pigtail

A processing device and butterfly cable technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of reducing work efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 is a processing method for butterfly cable pigtails disclosed by the present invention, comprising the following steps:

[0052] Step1, when producing the optical fiber pigtail of length a, first intercept the optical fiber of length 2a;

[0053] Step2. Install leather wire connectors at both ends of the optical fiber;

[0054] Step3, detecting the optical fiber whose length is 2a;

[0055] Step4. After the detection is completed, the optical fiber with a length of 2a is cut into two optical fiber pigtails with a length of a;

[0056] In Step1, when cutting the optical fiber, it is cut by winding. In the process of cutting the optical fiber, a mark is added to the optical fiber with a length of a. After the optical fiber with a length of a is wound, the winding is stopped. Use a marker pen or wrap a deformable material similar to a steel wire for marking. When marking, you can reserve 10-20cm of optical fiber material. After adding the mark, wrap the rubb...

Embodiment 2

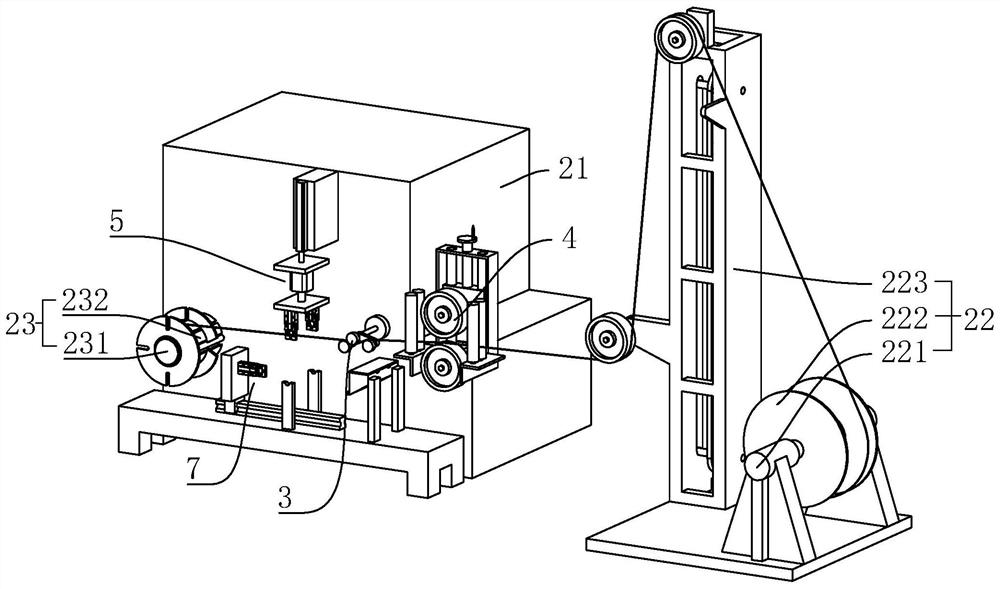

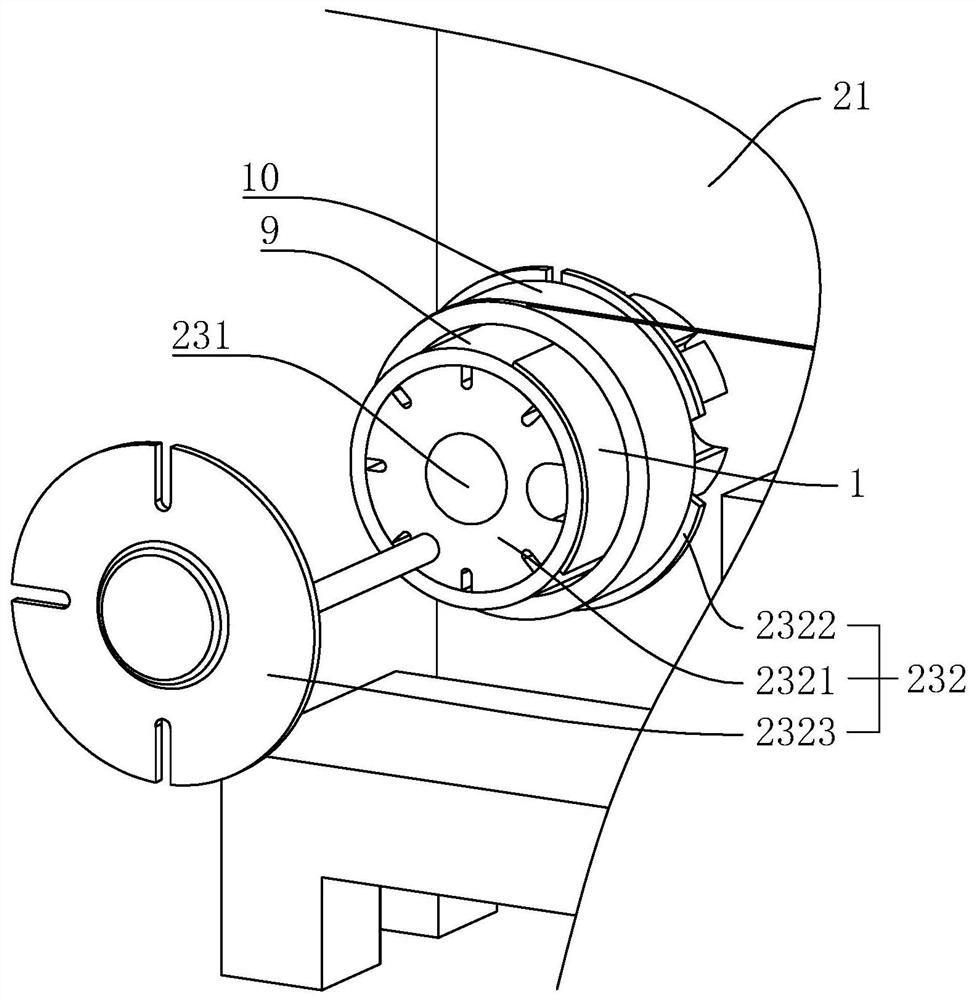

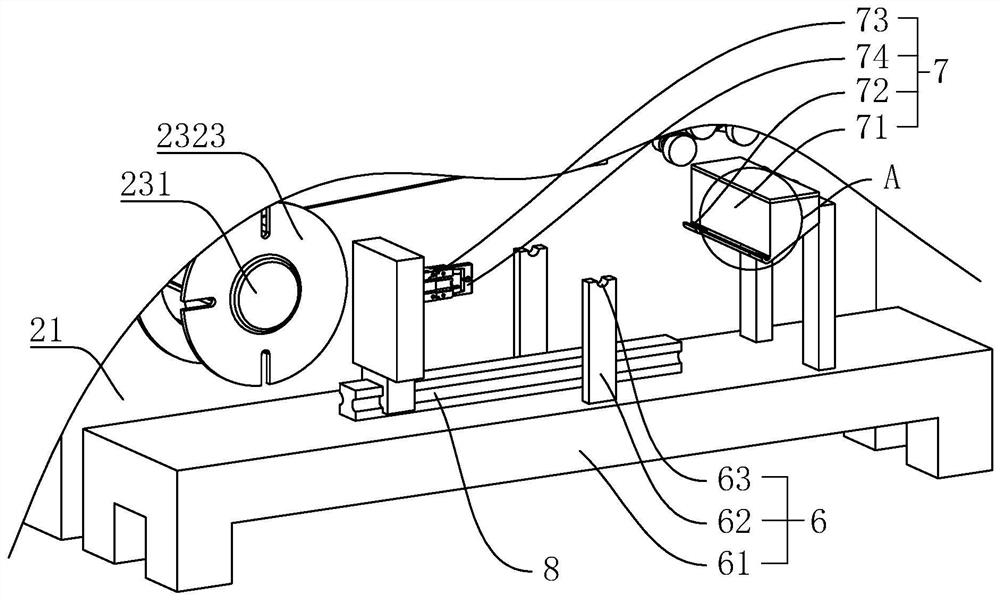

[0057] Embodiment two, such as figure 1 As shown, a processing device for butterfly optical cable pigtails includes a sheath cable cutting machine, and the sheath cable cutting machine includes a frame 21, an unwinding assembly 22 and a winding assembly 23 arranged on the frame 21, During the operation of the leather wire cable mining machine, the unwinding assembly 22 cooperates with the winding assembly 23 to realize the unwinding and winding of the optical fiber, and a guiding swing is provided between the unwinding assembly 22 and the winding assembly 23 Component 3, the guiding and swinging component 3 can make the optical fibers be arranged in an orderly manner during the winding process. An automatic winding component 5 and an automatic feeding component 7 are arranged between the guiding and swinging component 3 and the winding component 23. The material component 7 and the automatic winding component 5 can cooperate with each other to realize the winding and marking o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com