Automobile part cleaning equipment

A technology for cleaning equipment and auto parts, which is applied in the field of auto parts processing, can solve problems such as uncleanness and difficulty in cleaning, and achieve the effect of avoiding time-consuming and laborious, good cleaning effect, and strengthening the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

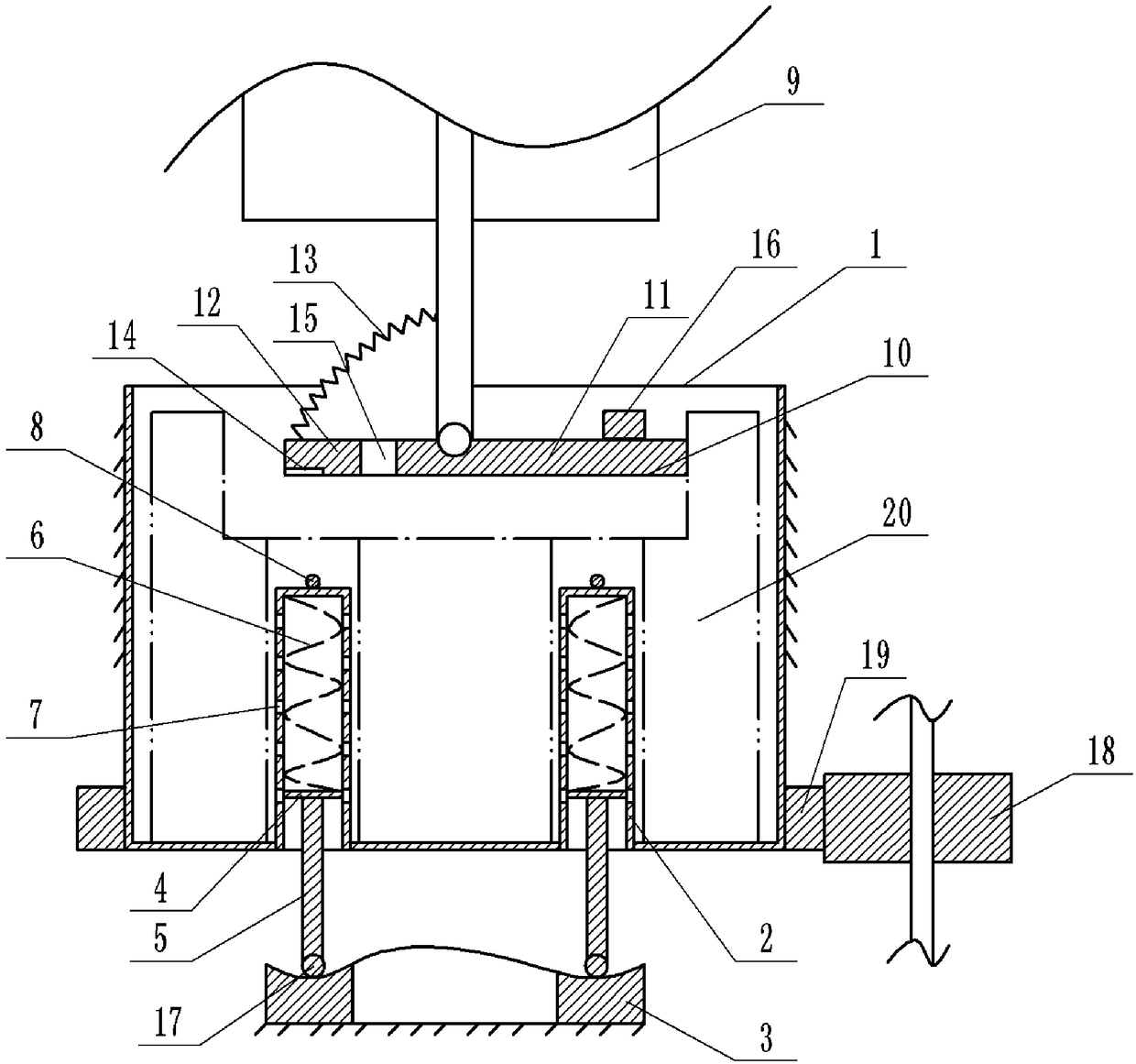

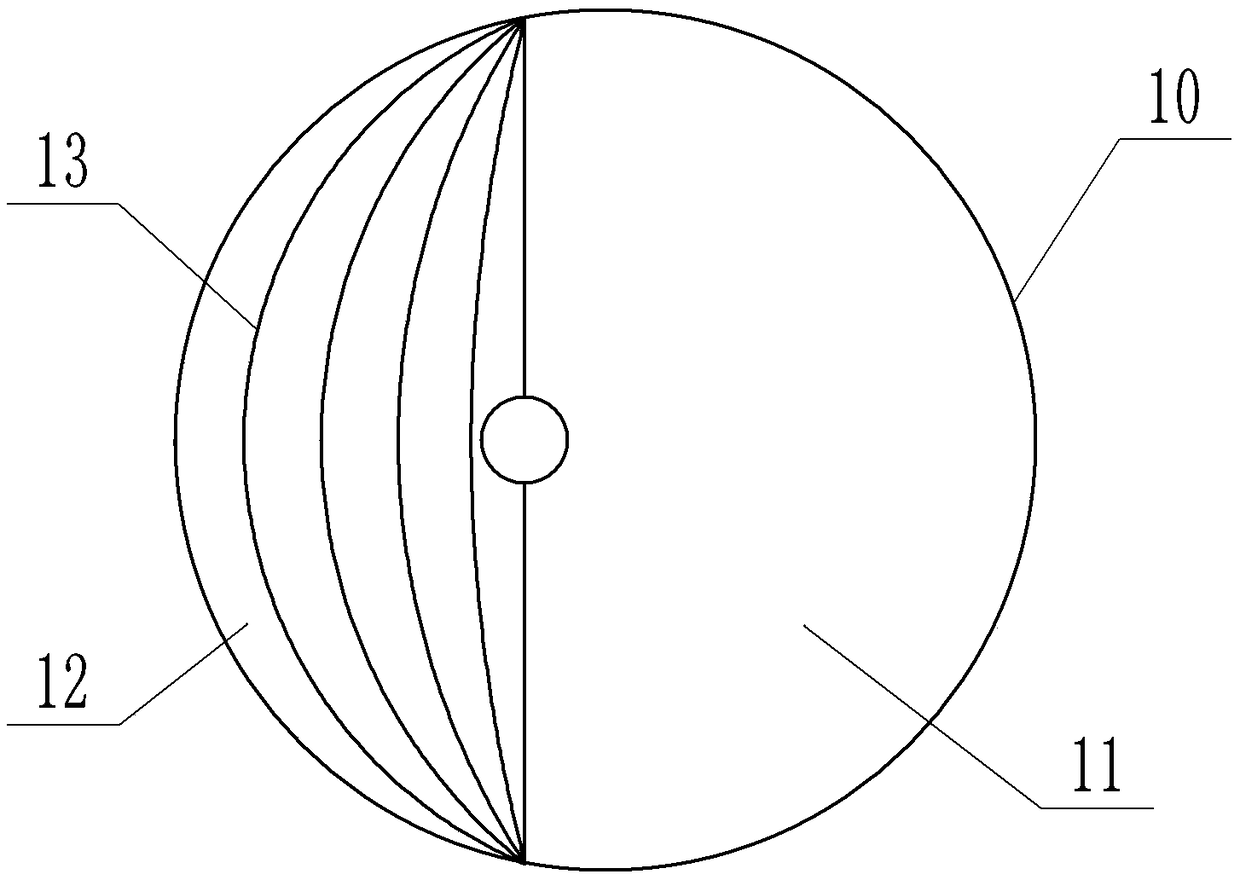

[0021] Further detailed explanation through specific implementation mode below:

[0022] The reference signs in the drawings of the description include: cleaning cylinder 1, cleaning roller 2, end face cam 3, piston plate 4, piston rod 5, spring 6, cleaning hole 7, first magnet 8, driving cylinder 9, scrubbing plate 10, Long part 11, short part 12, corrugated air bag 13, second magnet 14, air outlet 15, counterweight 16, spherical ball 17, gear 18, ring gear 19, parts 20.

[0023] The implementation of auto parts cleaning equipment such as figure 1 Shown: including the frame, the cleaning drum 1 rotatably connected to the frame, the driving mechanism for driving the cleaning drum 1, the cleaning roller 2 rotating and sealingly connected in the cleaning drum 1, the end face cam 3 arranged under the cleaning drum 1 and The scrubbing mechanism that is installed on the frame above the cleaning cylinder 1 and can clean the inner wall of the parts. The driving mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com