Pulse accelerator control device

A throttle control and pulse technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of wasting gasoline and high cost, and achieve the effect of saving electricity or fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

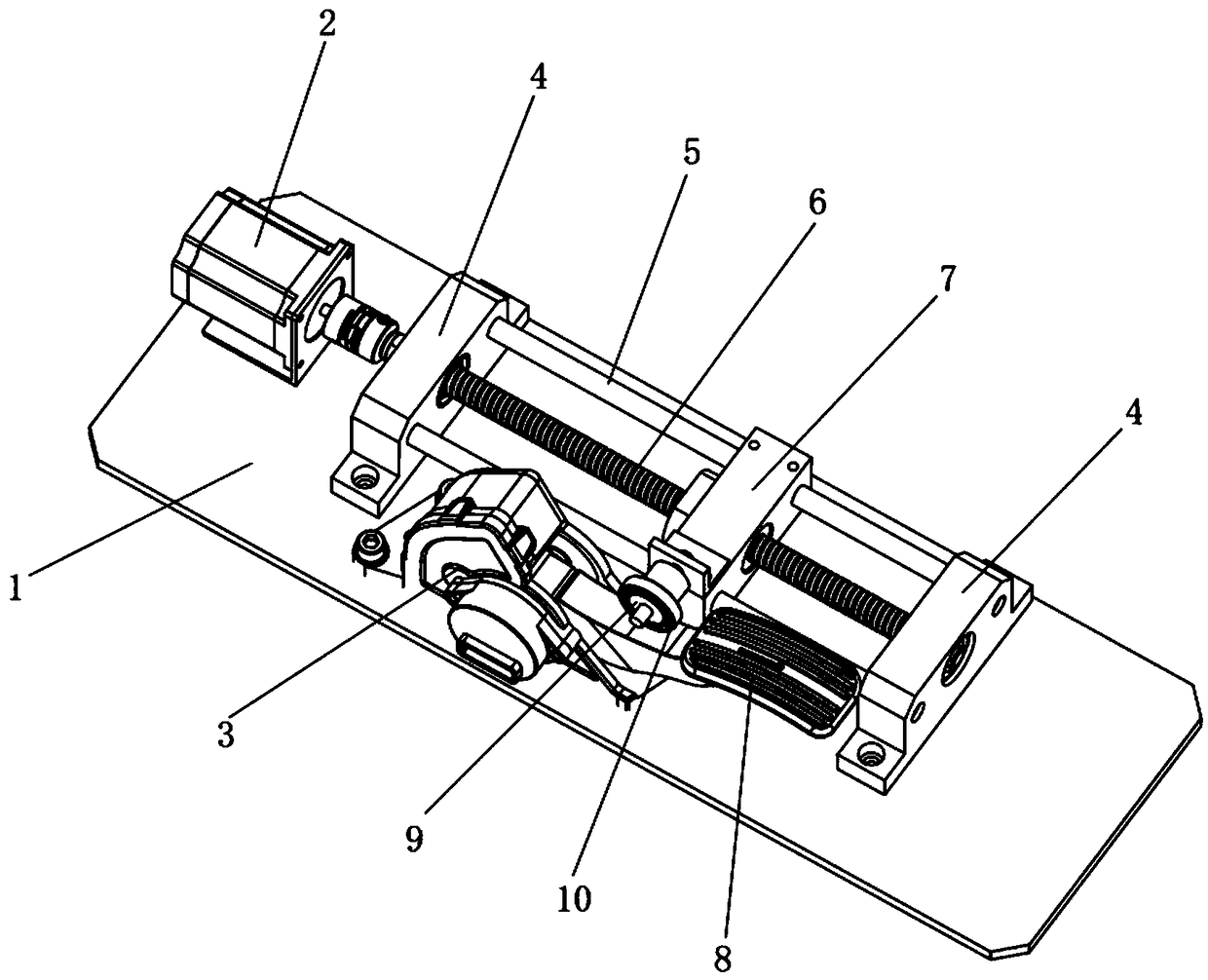

[0016] The invention discloses a pulse throttle control device, such as figure 1 As shown, it includes: a base plate 1, and a stepper motor 2, a support frame 4 and a potential control sensor 3 arranged on the base plate 1; the support frame 4 is provided with a slide bar 5 and a transmission screw 6; the slide bar 5 Set side by side on the support frame 4; the transmission screw mandrel 6 is rotatably installed on the support frame 4, and one end is connected with the output shaft of the stepper motor 2; block 7; the slider 7 can reciprocally slide along the slide bar 5; the slider 7 is provided with a pressing wheel 9; the potential control sensor 3 is provided with a pressing bar 8 linked with it; the pressing wheel 9 It is in conflict with the pressure rod 8 and can slide along its surface; the pressure wheel 9 is sleeved with a bearing 10; the pressure rod 8 is arranged in an inclined shape.

[0017] Preferably, when the present invention is applied to an electric vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com