Aviation blade leading and trailing edge laser contourgraph

A laser profiler, aviation blade technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of inability to measure soft materials and ultra-thin objects, compensation errors of measuring end radius, interference effects, etc., so that no professional Effects of training, flexible use, and low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

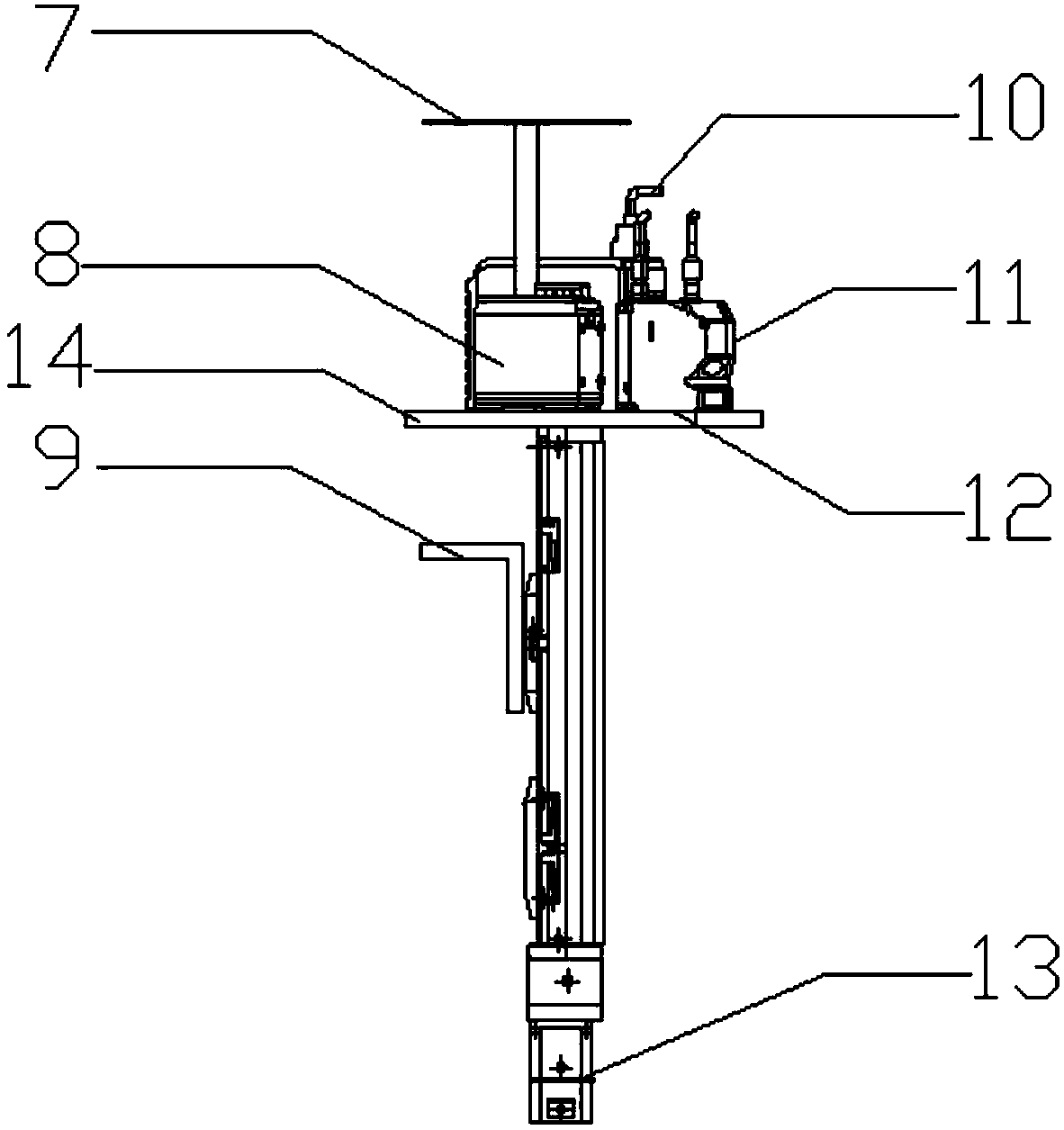

[0036] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

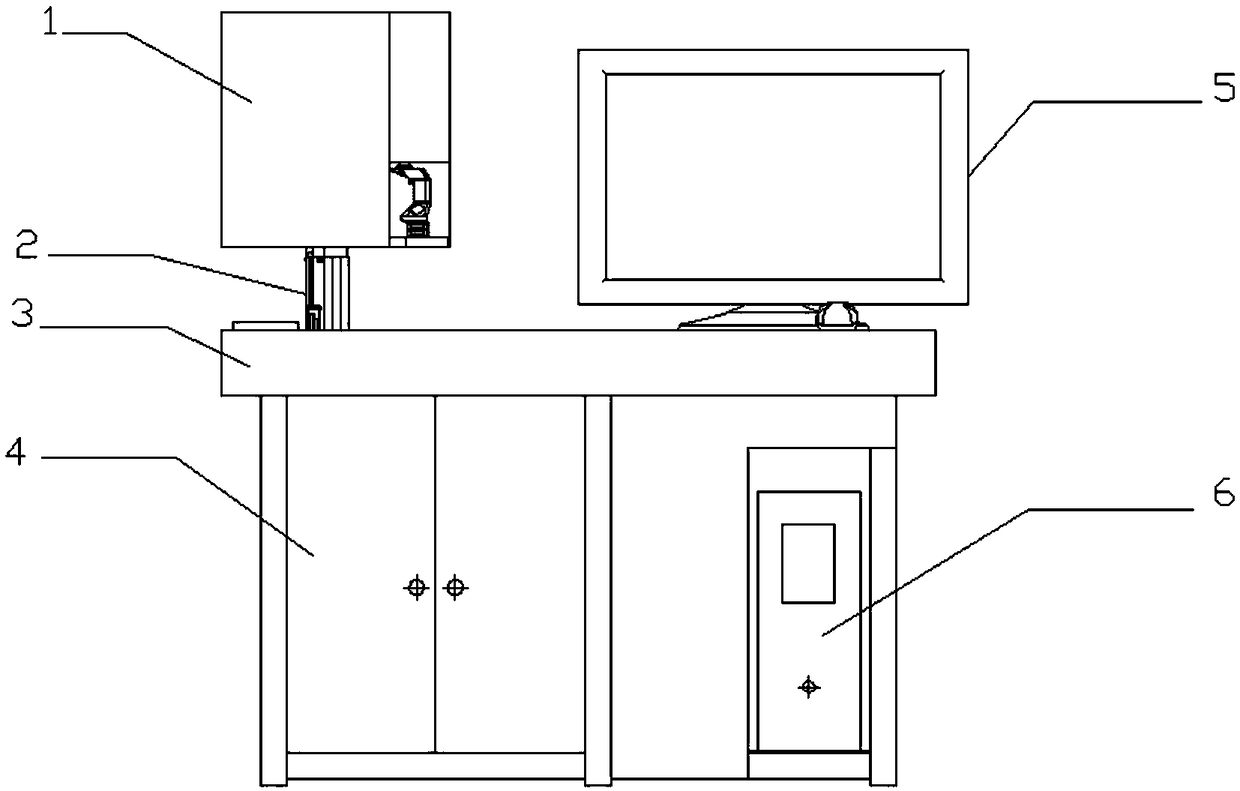

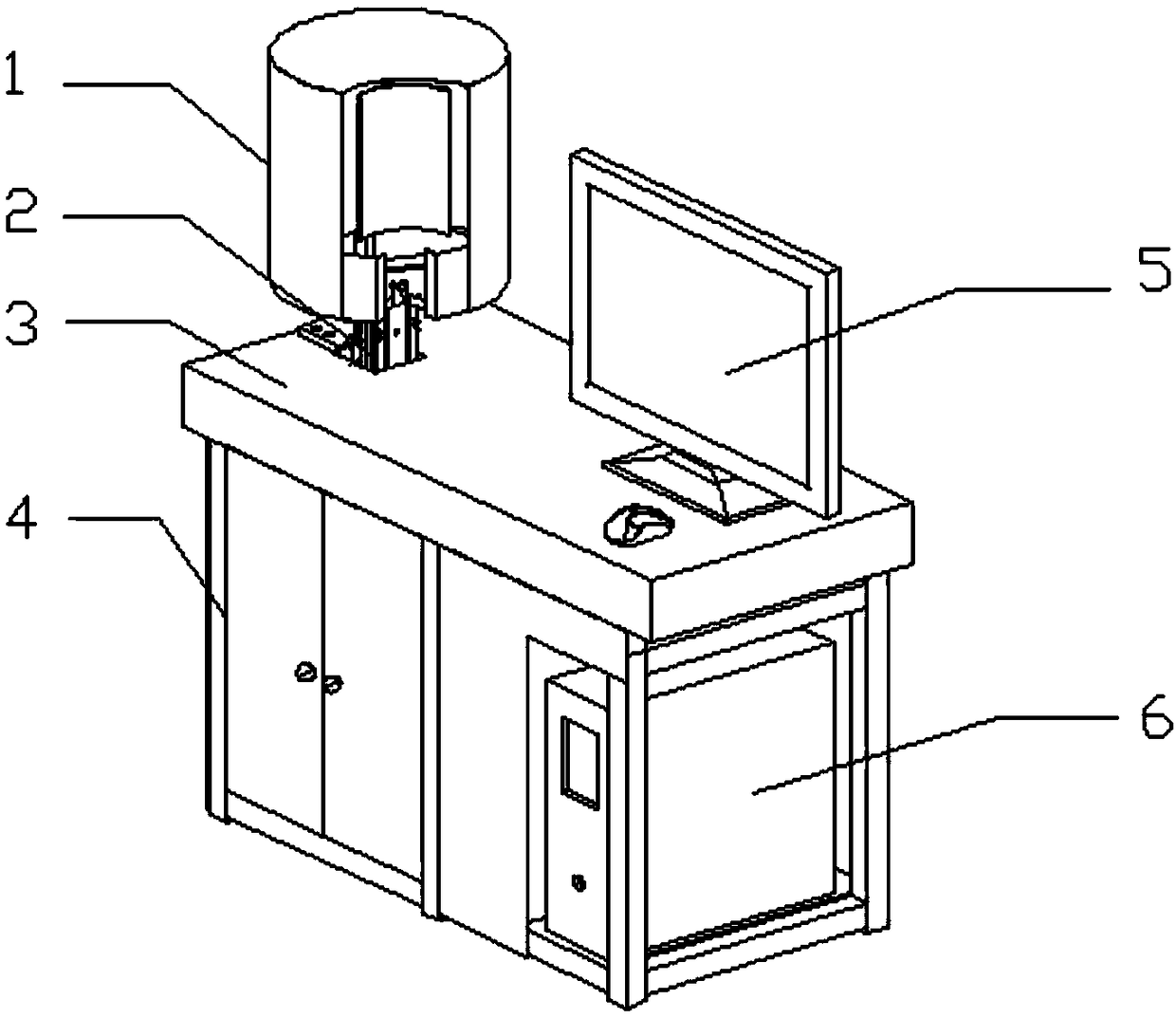

[0037] A laser profiler for the leading and trailing edges of aviation blades, comprising a servo motion device, a sensor measuring device and a measuring platform. The sensor measurement device is fixed on the servo motion device, and the servo motion device is fixed on the measurement platform. The sensor measurement device and the servo motion device are respectively connected with the main control computer 6 of the measurement platform, and the main control computer 6 controls the movement of the sensor measurement device and the servo motion device. .

[0038] The measuring platform includes a marble table 3, a control cabinet 4, a display and a main control computer 6; the marble table 3 is fixed on the upper surface of the control cabinet 4, and is provided with a square hole for fixing a sensor meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com