Flatness detecting device

A detection device and flatness technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as low accuracy and low work efficiency, and achieve the effects of simple operation, ensuring detection accuracy, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

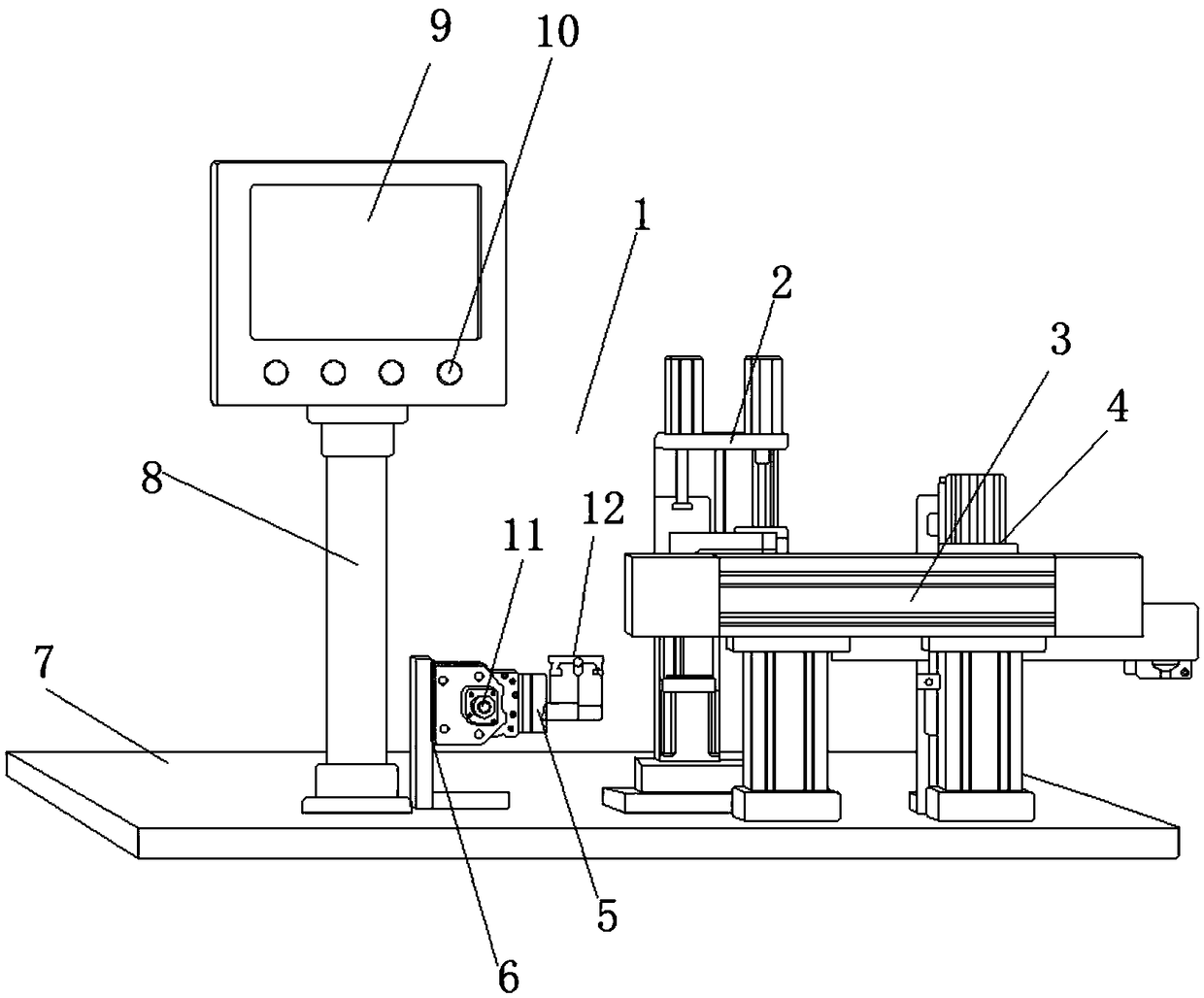

[0029] Such as Figure 1-5 As shown, the present invention provides a flatness detection device, which includes a device body 1, a base plate 7 is provided at the bottom of the device body 1, an operation panel 9 is installed at one end of the device body 1, and a support rod 8 is provided at the bottom end of the operation panel 9. , one side of the support rod 8 is equipped with a feeding seat 6, one side of the feeding seat 6 is equipped with a leveling device 2 and an air claw device 3, and one side of the leveling device 2 is provided with an unloader 4;

[0030] A feed seat cylinder 11 is installed on the feed seat 6, and one end of the feed seat 6 is provided with a telescopic rod 5, and one end of the telescopic rod 5 is provided with a first product seat 12;

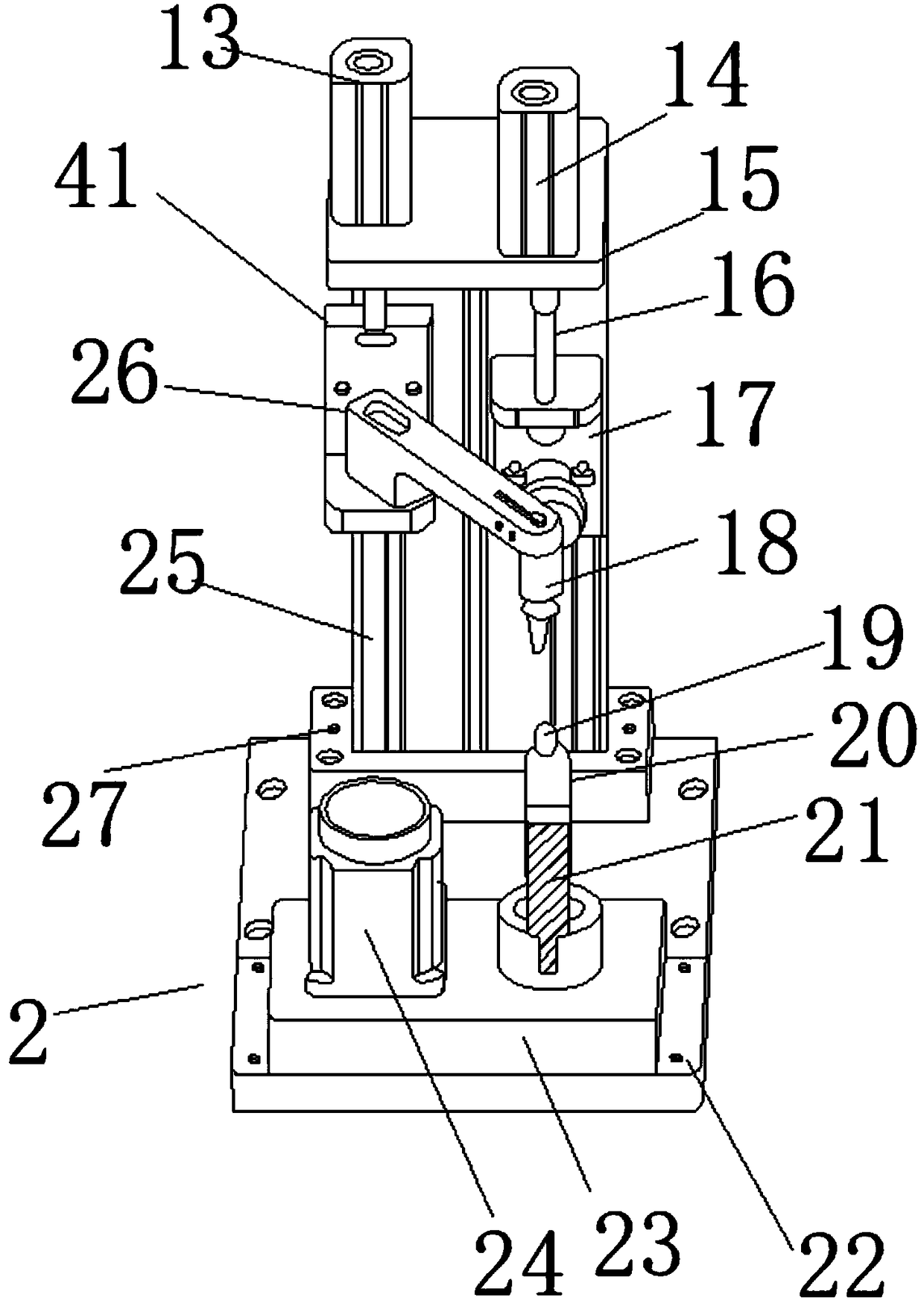

[0031]The bottom end of the leveling device 2 is provided with a base 22, one end of the base 22 is provided with a first fixed plate 23, the other end of the base 22 is provided with a second fixed plate 27, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com