Screen electromagnetic vibration device applied to laser light source projection and capable of eliminating speckle

A technology of laser light source and electromagnetic vibration, applied in projection devices, optics, optical components, etc., can solve the problems of high equipment cost, vibration energy loss, and soft vibration transmission medium, and achieve short vibration transmission distance, low vibration energy loss, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

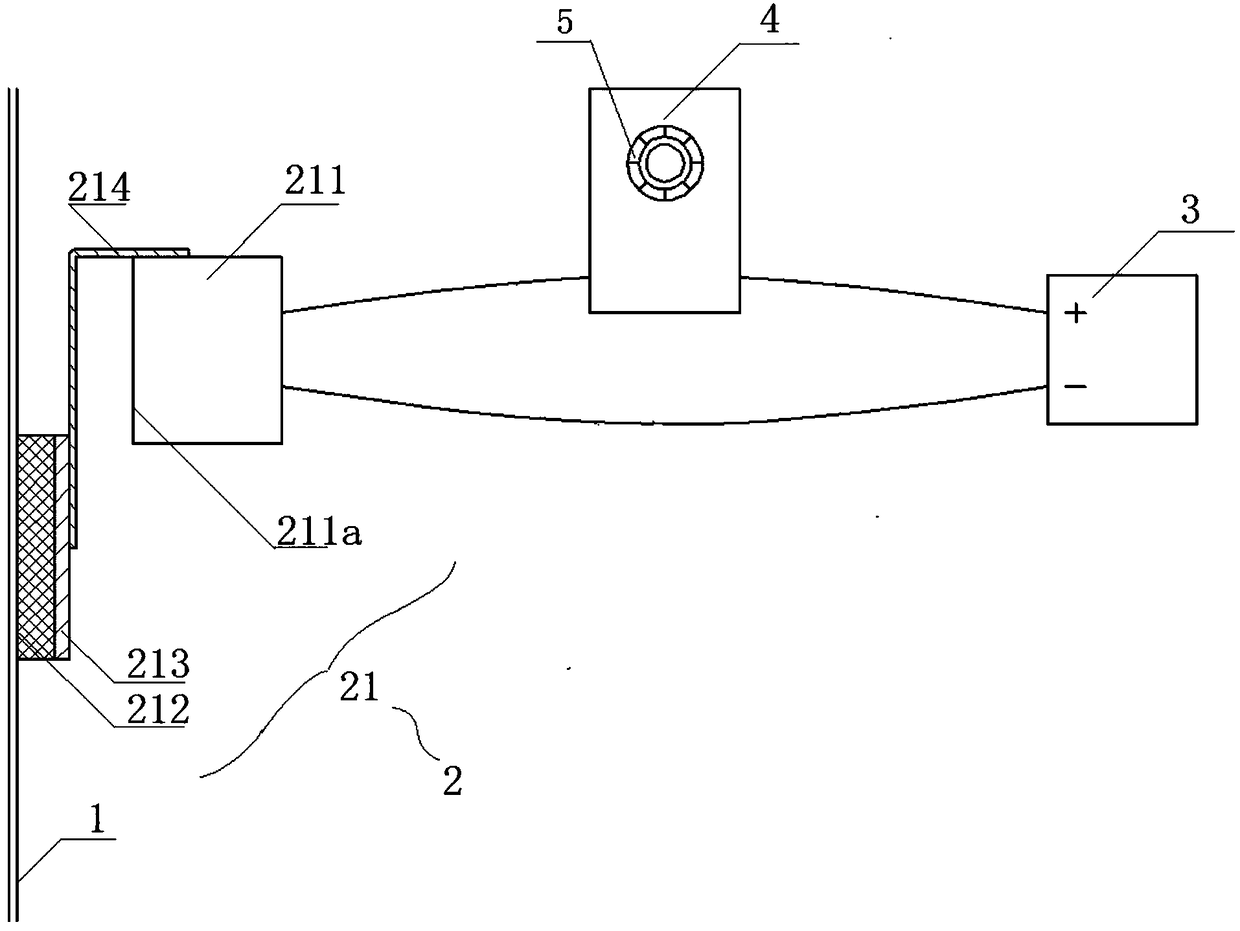

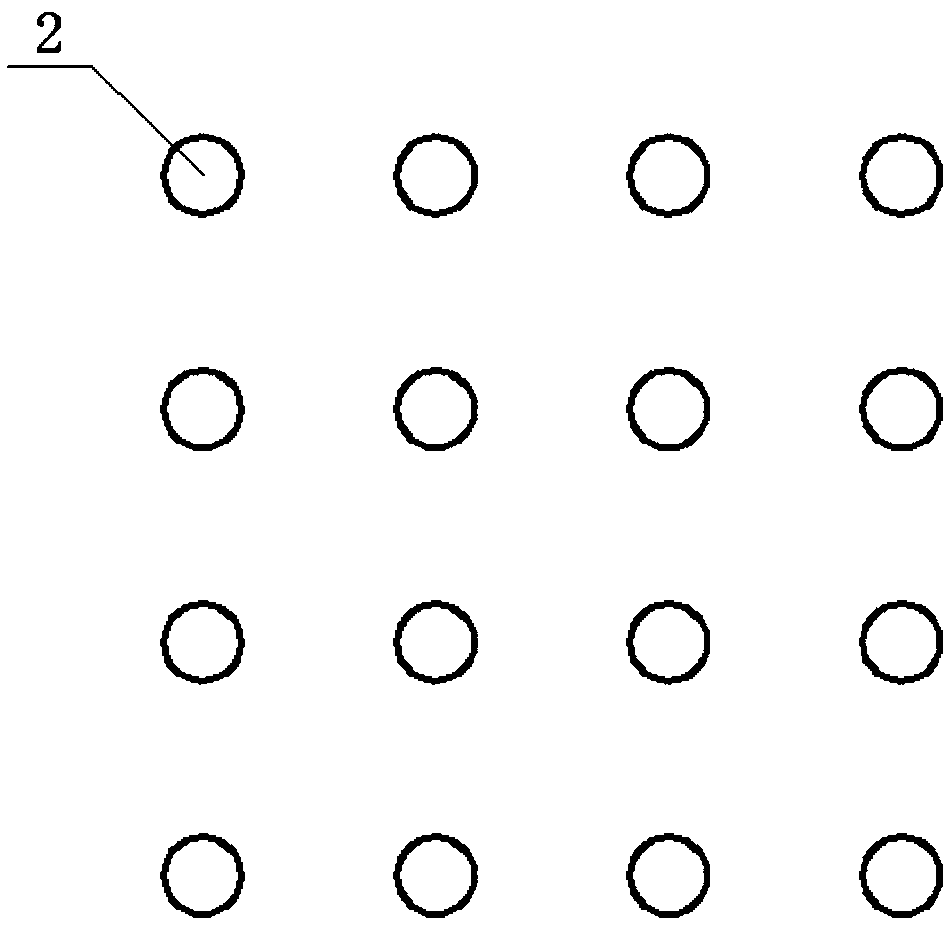

[0036] like Figure 1 to Figure 3 As shown, a screen electromagnetic vibration device applied to laser light source projection to eliminate speckle, including a screen 1, the back of the screen 1 is provided with a vibration unit 2 that drives the screen to vibrate by electromagnetic force to eliminate speckle, and the vibration unit 2 There are several evenly arranged on the screen 1 .

[0037] The vibration unit 2 is a contact structure 21 that directly drives the screen to vibrate.

[0038] The contact structure 21 includes an electromagnetic coil 211, a vibration transmission layer 212 connected to the screen 1, a vibration transmission block 213 connected to the vibration transmission layer 212, one end connected to the vibration transmission block 213 and the other end connected to the electromagnetic coil 211. The vibrating reed 214 on.

[0039] The vibrating reed 214 is arranged parallel to 1 cm in front of the magnetic generating end 211 a of the electromagnetic coi...

Embodiment 2

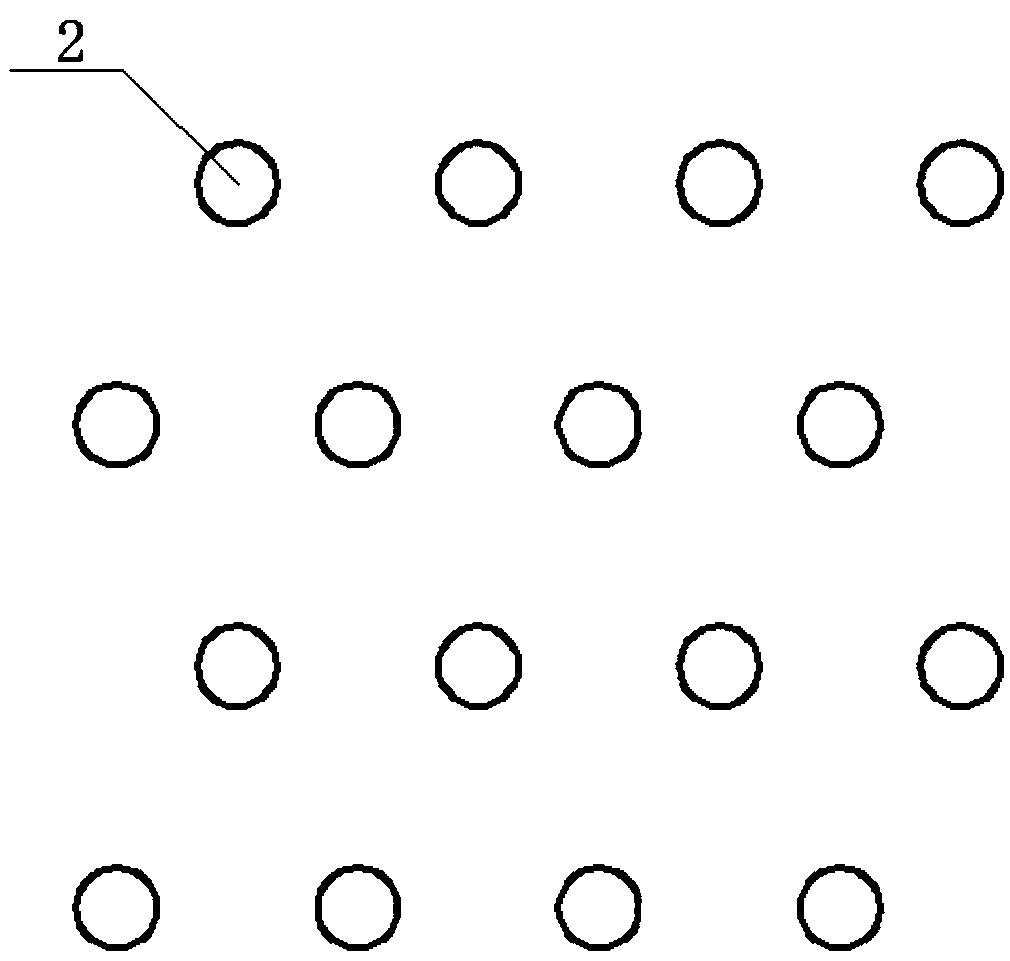

[0050] like Figure 4 , Figure 5 As shown, a screen electromagnetic vibration device applied to laser light source projection to eliminate speckle, including a screen 1, the back of the screen 1 is evenly distributed with several vibration units 2 that drive the screen to vibrate by electromagnetic force to eliminate speckle. The vibration units 2 are distributed in a lattice arrangement.

[0051] The vibration unit 2 is a non-contact structure 22 that indirectly drives the screen to vibrate.

[0052] The vibration units 2 are arranged at equal intervals on the upper and lower sides or around the screen 1 .

[0053]The non-contact structure 22 includes an electromagnetic coil 211, a permanent magnet block 221 connected to the back of the screen 1 and placed above the magnetic generating end 211a of the electromagnetic coil 211; the permanent magnetic block 221 is located at the magnetic generating end 211a of the electromagnetic coil 211 1cm above.

[0054] One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com