Arc extinguishing nozzle and preparation method thereof

A technology of arc extinguishing nozzle and polytetrafluoroethylene, which is applied in the direction of high-voltage air circuit breaker, high-voltage/high-current switch, electrical components, etc., can solve the problem of high material cost, achieve the goal of improving overall performance, saving sintering time, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

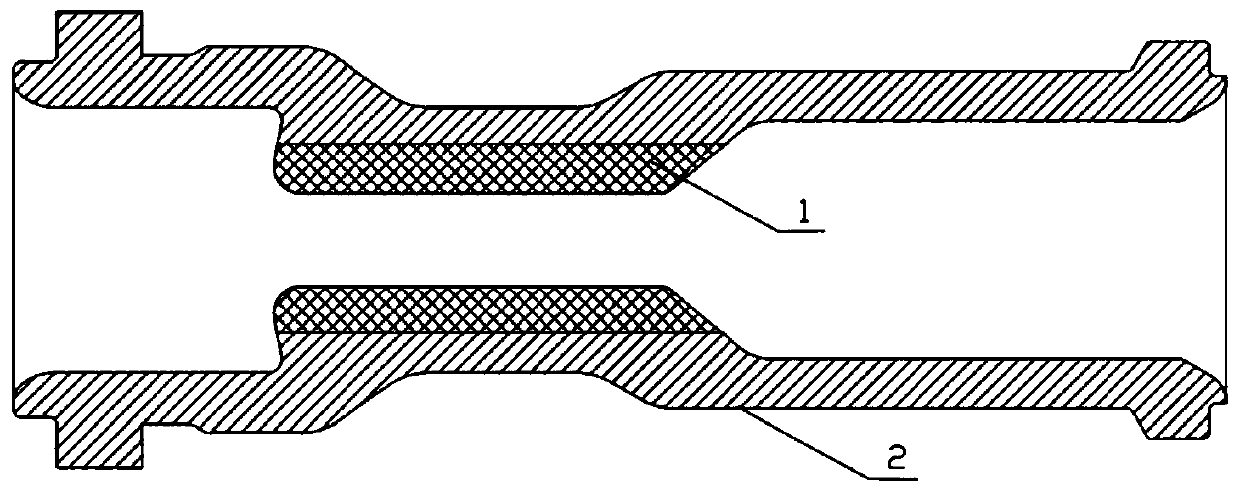

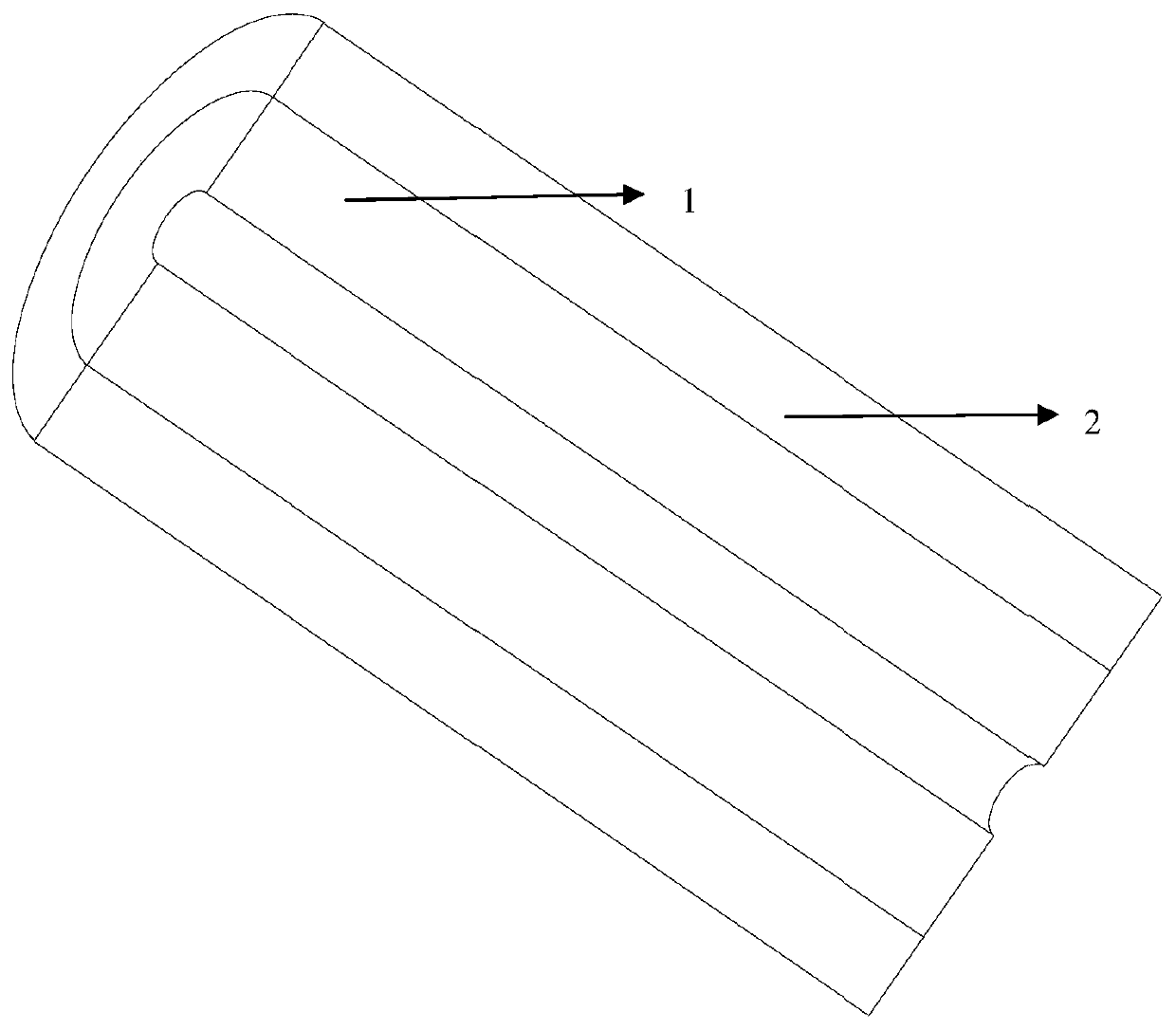

[0042] The arc extinguishing nozzle of this embodiment is a functional gradient type arc extinguishing nozzle, and the structure is as follows figure 1 shown. The arc extinguishing nozzle is obtained by cutting an arc extinguishing nozzle blank, and includes an inner functional layer 1 and an outer functional layer 2 . The structure of the arc extinguishing nozzle blank is as follows figure 2 As shown, it includes an inner functional layer 1 and an outer functional layer 2 arranged radially from inside to outside. The inner functional layer is composed of polytetrafluoroethylene and molybdenum disulfide, wherein molybdenum disulfide accounts for 0.3% of the mass of the inner functional layer. The outer functional layer is composed of polytetrafluoroethylene and boron nitride, wherein boron nitride accounts for 5% of the mass of the outer functional layer.

[0043] The preparation method of the arc extinguishing nozzle of the present embodiment comprises the following steps...

Embodiment 2

[0049] The arc extinguishing nozzle of this embodiment is a functional gradient type arc extinguishing nozzle, and the structure is as follows figure 1 shown. The arc extinguishing nozzle is obtained by cutting the arc extinguishing nozzle blank. The structure of the arc extinguishing nozzle blank is as follows: figure 2 As shown, it includes an inner functional layer 1 and an outer functional layer 2 arranged radially from inside to outside. The inner functional layer is composed of polytetrafluoroethylene and molybdenum disulfide, wherein molybdenum disulfide accounts for 0.2% of the mass of the inner functional layer. The outer functional layer is composed of polytetrafluoroethylene and boron nitride, wherein boron nitride accounts for 8% of the mass of the outer functional layer.

[0050] The preparation method of the arc extinguishing nozzle of the present embodiment comprises the following steps:

[0051] 1) According to the size of the inner and outer functional lay...

Embodiment 3

[0056] The arc extinguishing nozzle of this embodiment is a functional gradient type arc extinguishing nozzle, and the structure is as follows figure 1 shown. The arc extinguishing nozzle is obtained by cutting the arc extinguishing nozzle blank. The structure of the arc extinguishing nozzle blank is as follows: figure 2 As shown, it includes an inner functional layer 1 and an outer functional layer 2 arranged radially from inside to outside. The inner functional layer is composed of polytetrafluoroethylene and molybdenum disulfide, wherein molybdenum disulfide accounts for 0.5% of the mass of the inner functional layer. The outer functional layer is composed of polytetrafluoroethylene and boron nitride, wherein boron nitride accounts for 3% of the mass of the outer functional layer.

[0057] The preparation method of the arc extinguishing nozzle of the present embodiment comprises the following steps:

[0058] 1) According to the size of the inner and outer functional lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com