Cathode for magnetic plasma power thruster

A magnetic plasma and thruster technology, applied in the field of magnetic power, can solve the problems of cathode cracking and low emission efficiency, and achieve the effects of strong electron emission capability, enhanced plasma, and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A nanocomposite doped magnetic plasma power thruster cathode, directly adding nano oxides and alloy elements and metal elements with magnetic corresponding. The key to the thermal emission stability and long life of the tungsten electrode with oxide added is that the melting point and work function of the oxide are lower than those of pure tungsten, and the ablation rate is faster than that of tungsten. During the working process, the oxide in the matrix tungsten migrates and diffuses in time The surface of the electrode is used to replenish the oxides lost by surface evaporation. The oxide particles on the electrode surface are easy to cause discharge, and the subsequent discharge process is easy to occur on these oxides. Adding a certain amount of metal alloy elements can improve the density, toughness and thermal stability of the electrode, and can also reduce ablation and control the diffusion of oxides. Adding a certain amount of metal alloy elements can improve th...

Embodiment 2

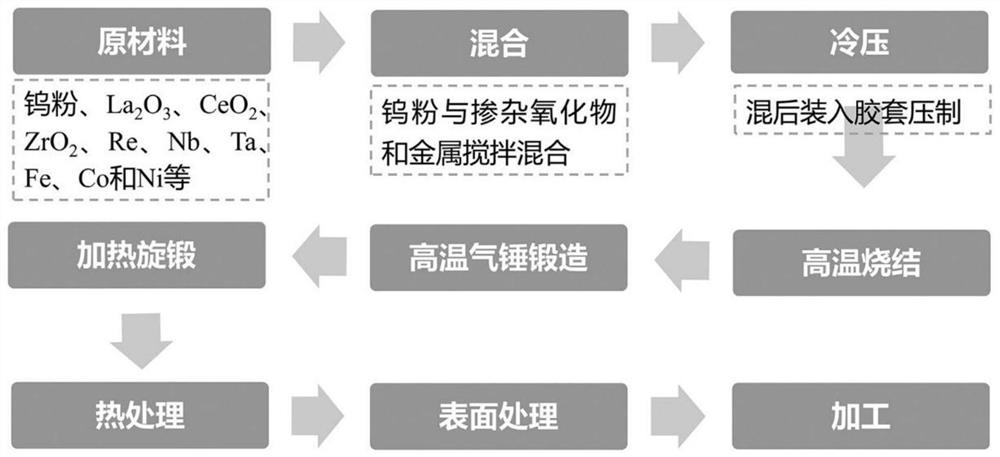

[0046] Based on Example 1, using the powder metallurgy method, by adding CeO 2 , ZrO 2 and La 2 o 3 Nano-scale oxides such as Re, Nb, Ta, Fe, Co, Ni and other alloy elements with magnetic response are mixed with tungsten powder and pressed and sintered to prepare a nanocomposite doped magnetic plasma power thruster cathode. The thruster cathode material has a lower work function than the tungsten electrode, which greatly reduces the working temperature of the electrode, reduces ablation, stabilizes the arc plasma, and improves the service life of the thruster cathode. The specific preparation method is as figure 1 shown.

[0047] The preparation of nano-composite doped magnetic plasma power thruster cathode includes nine stages of raw material selection, raw material mixing, cold pressing, high temperature sintering, high temperature air hammer forging, heating swaging, heat treatment, surface processing and cathode processing.

[0048] Preferably, the selected tungsten p...

Embodiment 3

[0063] A composition for the cathode of a magnetoplasma power thruster, in mass percentage, the composition is composed of the following compounds:

[0064] Doped oxides and alloying elements with a mass percentage not exceeding 20%;

[0065] Metal elements with magnetic response not exceeding 5% by mass;

[0066] The rest is tungsten;

[0067] The doped oxide is La 2 o 3 , CeO 2 , ZrO 2 One or more combinations of; the alloy element is one or more combinations of Re, Nb, Ta; the magnetically responsive metal element is one or more combinations of Fe, Co, Ni.

[0068] Preferably, the particle size of the tungsten powder is 0.5um-5.0um, and the oxygen content is ≤40ppm.

[0069] Preferably, the particle size of the doped oxide is 50nm-500nm.

[0070] A preparation method for a cathode of a magnetic plasma power thruster, using the above composition, comprising the steps of:

[0071] Mix tungsten powder, doped oxides, alloy elements, and metal elements with magnetic resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com