A kind of anti-ablation high-barrier flexible heat-proof soft skirt and preparation method thereof

An anti-ablation and high-barrier technology, which is applied in chemical instruments and methods, thermal protection devices for aerospace vehicles, transportation and packaging, etc., can solve the problems of reduced sealing performance, large overall thickness, and large single-layer thickness, etc., to achieve guaranteed Anti-ablation, good barrier air tightness, and the effect of reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

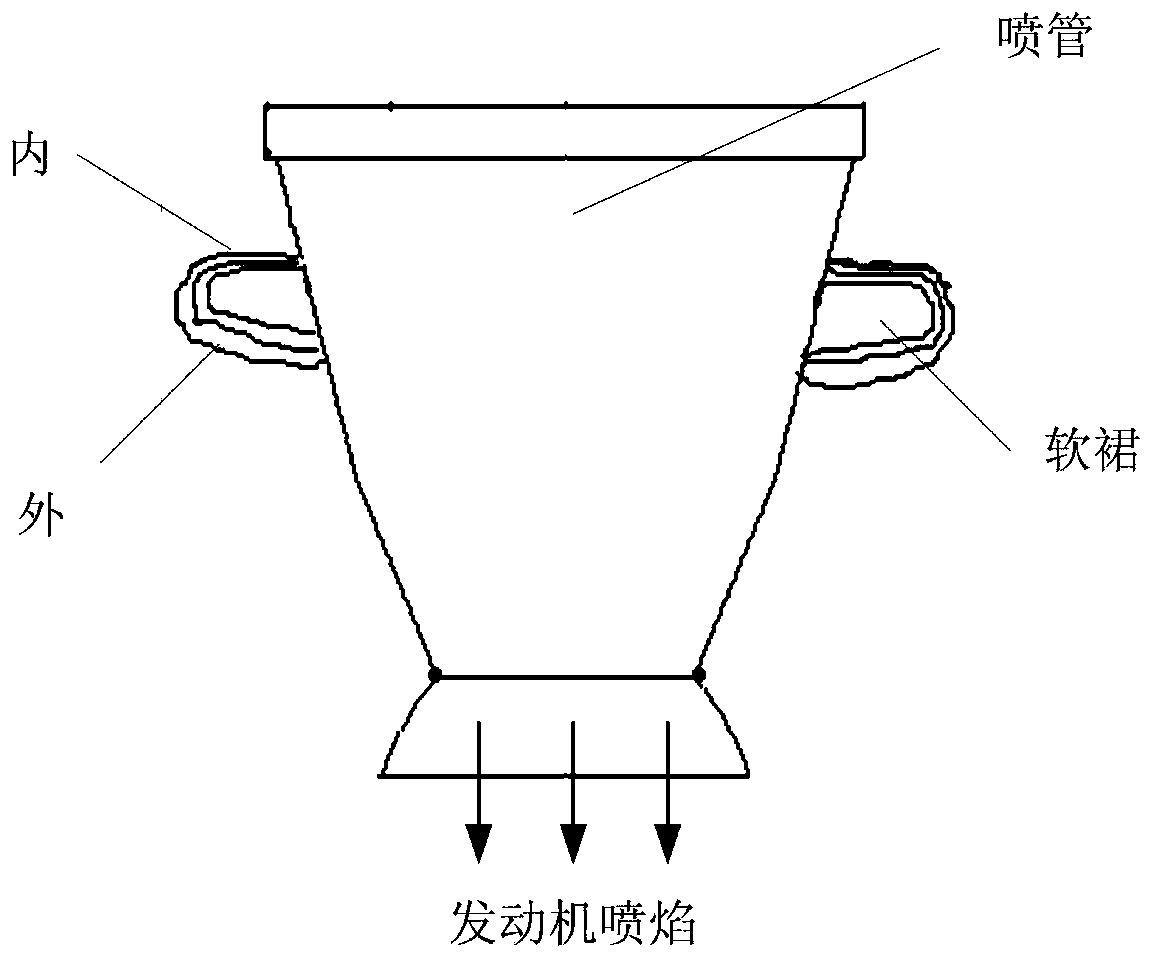

[0043] Soft skirt structure:

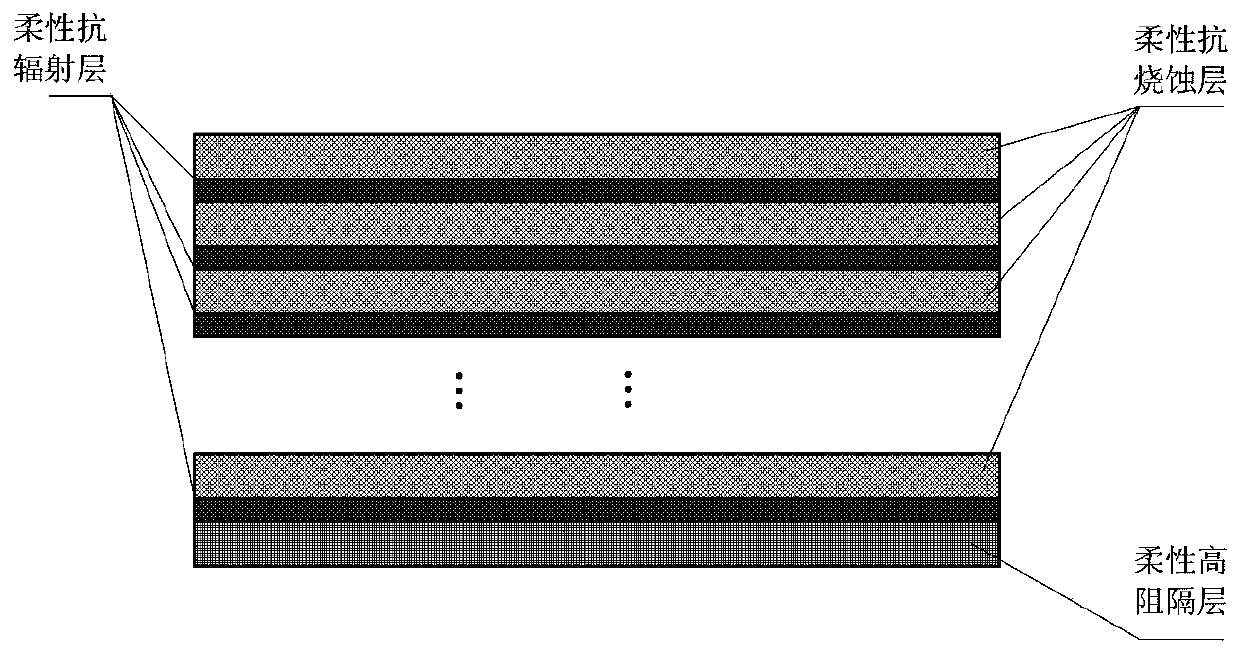

[0044] 4 layers of flexible anti-ablation layer, the content of phenolic resin in the flexible anti-ablation layer is 30%, 20%, 10%, 5%, respectively, and the thickness of each layer is 1.25mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexibility is high The barrier layer has 3 layers, and the thickness of each layer is 0.2mm; the total thickness of the soft skirt is 5.8mm.

[0045] Concrete preparation process is as follows:

[0046] Stir and mix 100 parts of HTV-1 methyl vinyl silicone rubber and 5 parts of benzoyl peroxide (BPO) evenly. Add 0%, 5%, 10%, 20%, 30% phenolic resin into the mixture respectively, mix well and set aside. Then choose the area density as 200g / m 2 The glass fiber plain weave cloth is double-sided coated on a silicone rubber coating machine, and vulcanized at 160-180°C after coating to obtain a silicone rubber-coated fabric. Then prepare aluminum foil with a thickness of 0.05 mm. After ...

Embodiment 2

[0049] Soft skirt structure:

[0050] The flexible anti-ablation layer has 3 layers, the content of phenolic resin in the flexible anti-ablation layer is 30%, 15%, 10%, and the thickness is 1.4mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexible high barrier layer is 3 layers, each Layer thickness 0.2; total thickness 4.95 mm.

[0051] The preparation process is the same as in Example 1.

[0052] The soft skirt prepared in this example is tested for ablation resistance and air tightness according to the relevant national standards of GJB2620-96. The ablation test conditions are: the heat flux in the first 70 seconds is 167.47KW / m 2 , the heat flux in the last 60 seconds is 376.81KW / m 2 After the ablation, inspection found that the surface of the first flexible high-barrier layer had slight ablation marks, and the remaining two flexible high-barrier layers had no ablation, and the airtightness was intact.

Embodiment 3

[0054] Soft skirt structure:

[0055] 5 layers of flexible anti-ablation layer, the content of phenolic resin in the flexible anti-ablation layer is 25%, 20%, 15%, 10%, 5%, and the thickness is 1.0mm; the flexible anti-radiation layer is made of 0.05mm aluminum foil; the flexibility is high The barrier layer has 3 layers, and the thickness of each layer is 0.2mm; the total thickness is 5.85mm.

[0056] The preparation process is the same as in Example 1.

[0057] The soft skirt prepared in this example is tested for ablation resistance and air tightness according to the relevant national standards of GJB2620-96. The ablation test conditions are: the heat flux in the first 70 seconds is 167.47KW / m 2 , the heat flux in the last 60 seconds is 376.81KW / m 2 , after the ablation inspection, it was found that the flexible high barrier layer was intact, no ablation was seen, and the airtightness was intact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com