Salt and alkali soil improvement device

A soil improvement and salinity-alkali technology, which is applied in the direction of soil lifting machinery, shovels, plows, etc., can solve the problems of low service life of the device, formation of salt damage, plant death, etc., to increase service life, improve crushing efficiency, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

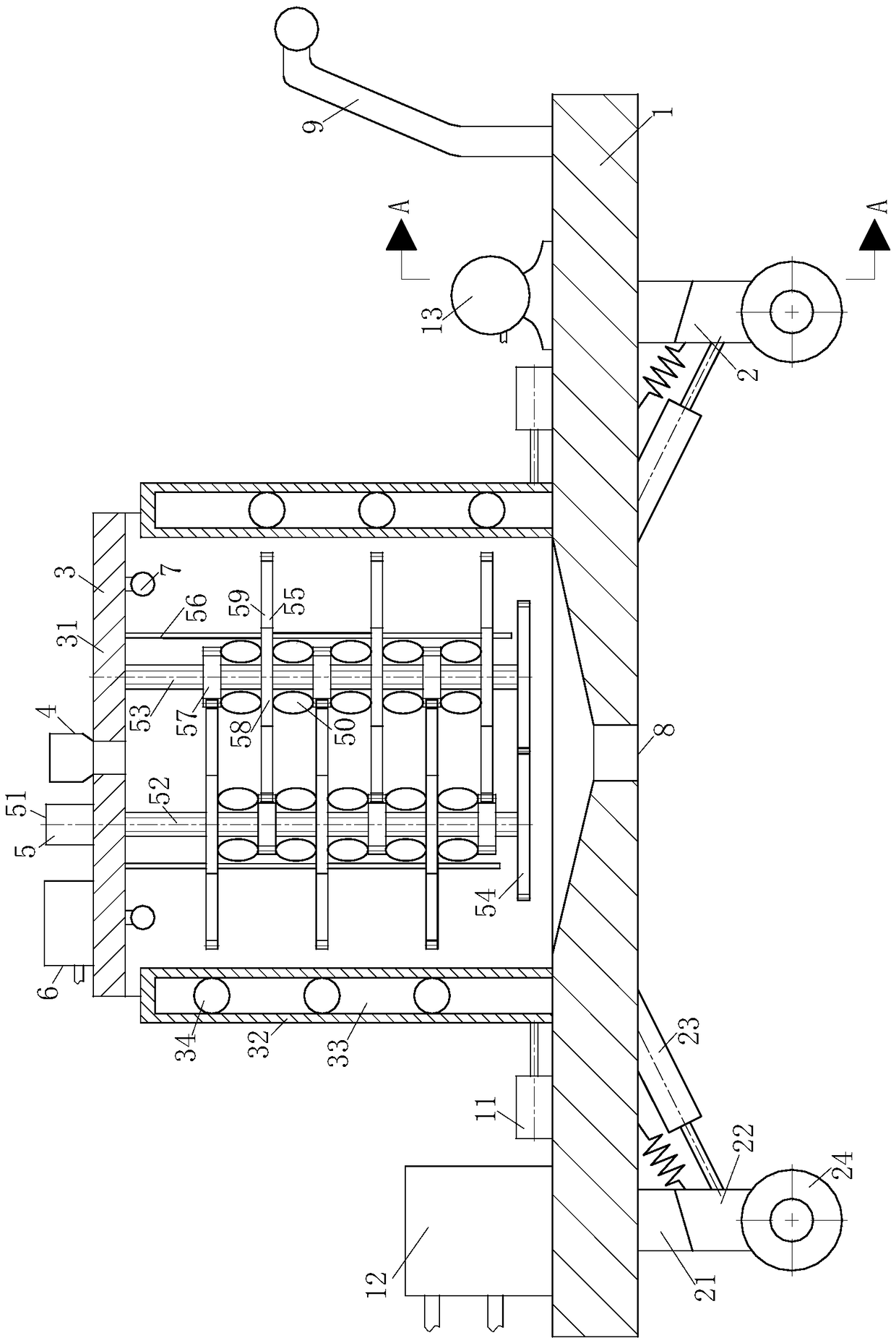

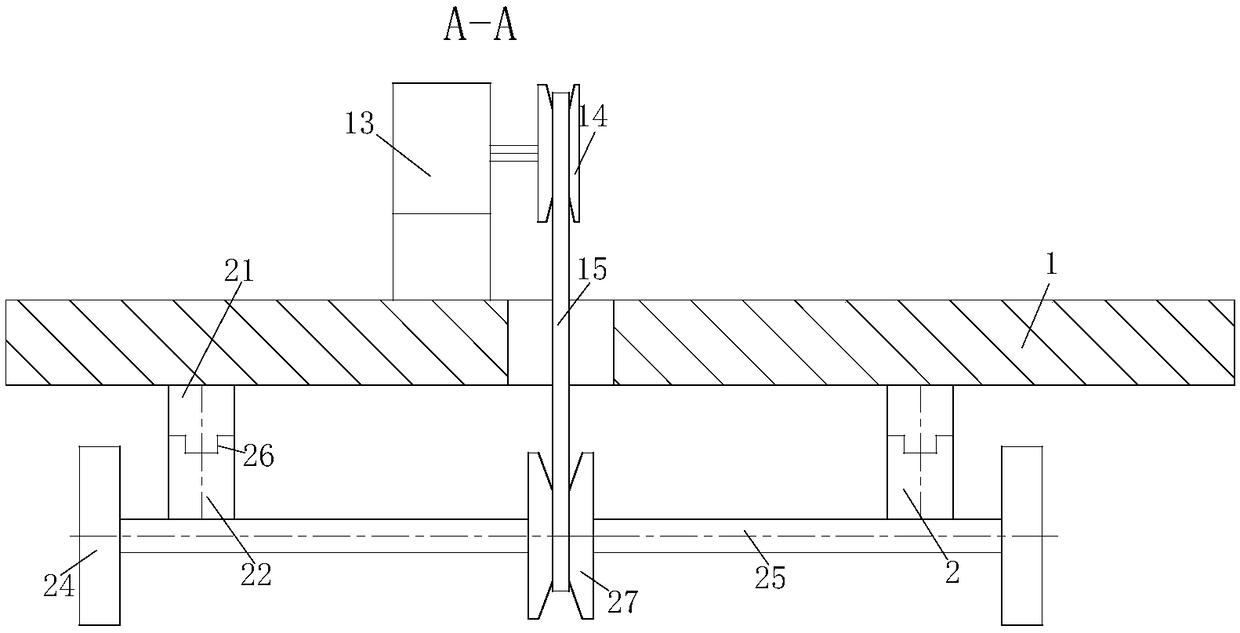

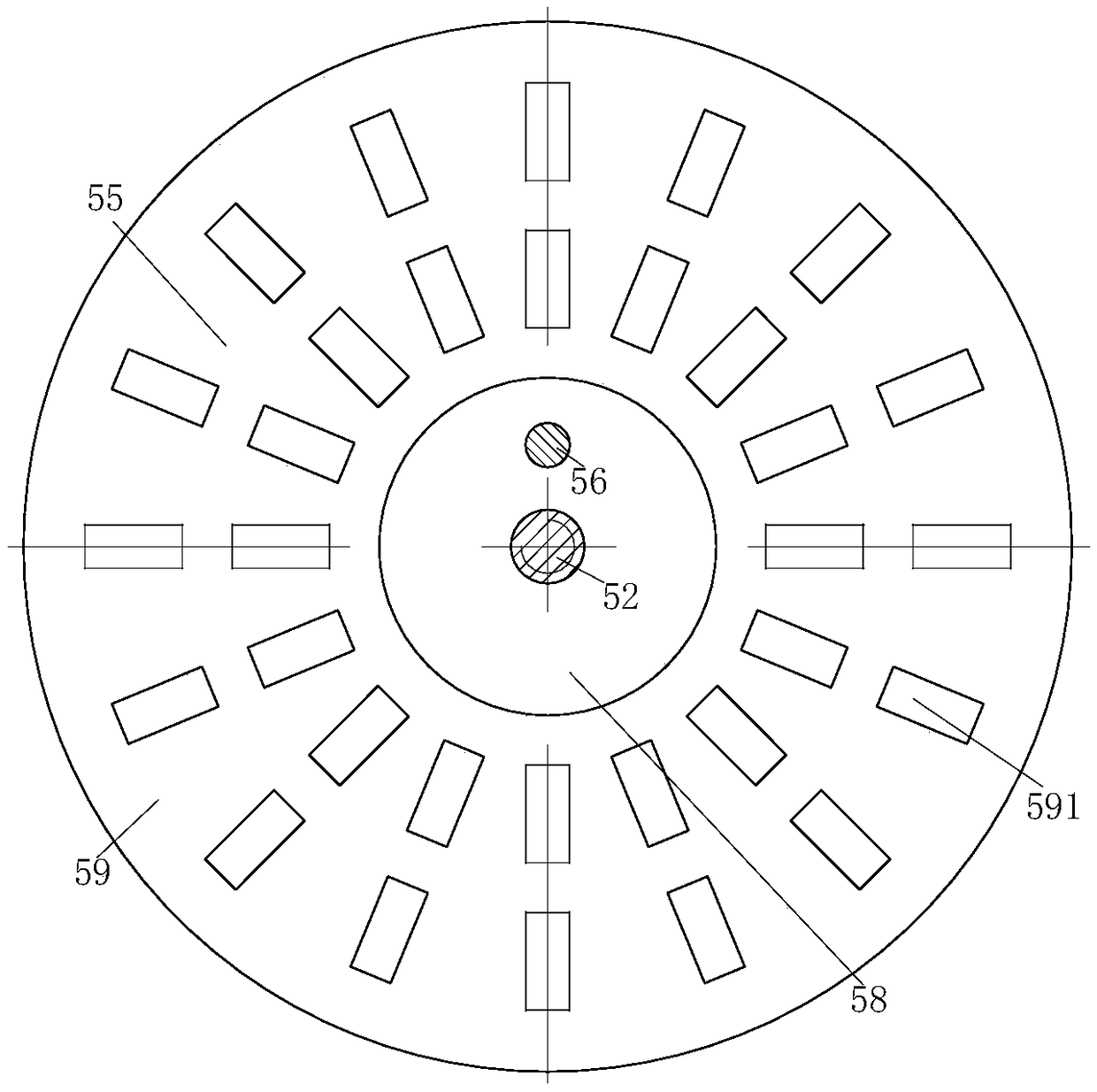

[0018] use Figure 1-Figure 3 The structure of the saline-alkaline soil improvement apparatus which concerns on one Embodiment of this invention is demonstrated below.

[0019] Such as figure 1 As shown, a kind of saline-alkaline soil improvement device according to the present invention includes a base plate 1, a moving module 2, a box body 3, a feed port 4, a crushing module 5, a medicine box 6, a nozzle 7, a discharge port 8 and Handrail 9; the movement module 2 is installed under the bottom plate 1, and the movement module 2 is used to drive the movement of the bottom plate 1; the box body 3 includes a main frame 31 and a panel 32 opposite to the left and right, and the main frame 31 is fixedly connected to the bottom plate 1 , the panel 32 can move left and right on the bottom plate 1; the feed port 4 is located at the top of the box body 3, and the feed port 4 is used to input soil into the box body 3; the crushing module 5 is located in the box body 3, and the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com