Peanut cleaning equipment for food processing

A technology for food processing and cleaning equipment, applied in food processing, application, food science and other directions, can solve the problems of restriction, large energy consumption, large water consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

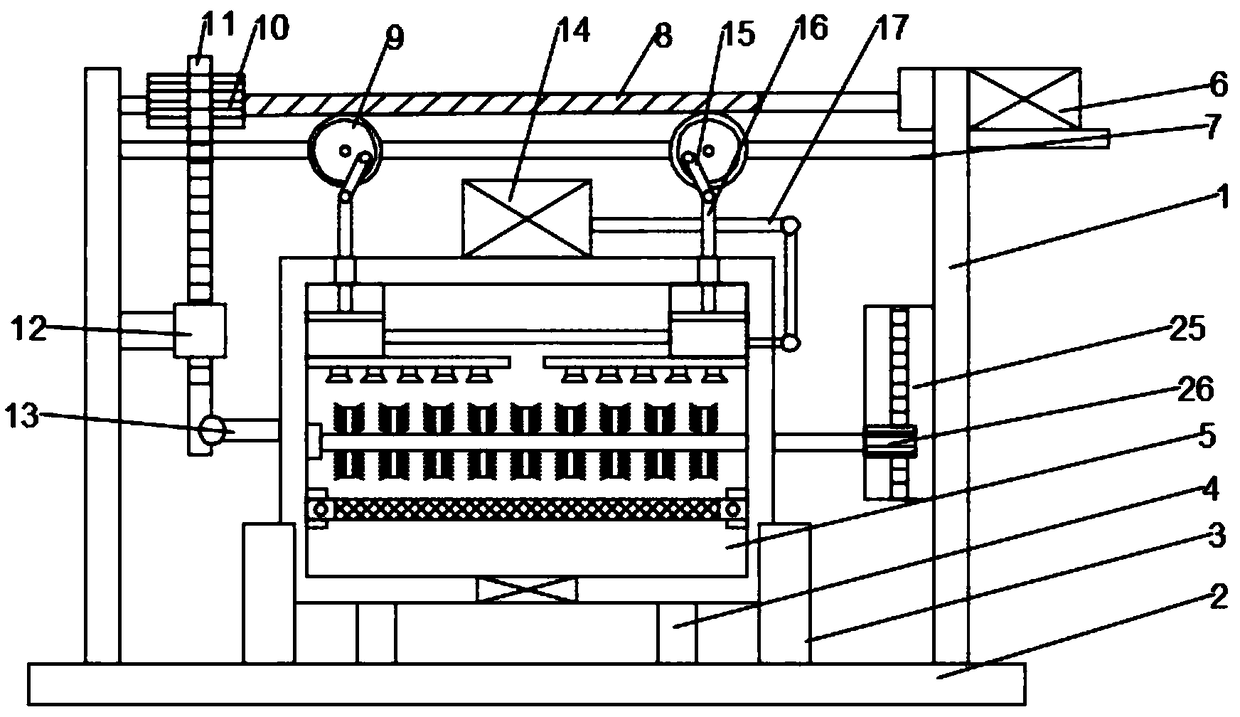

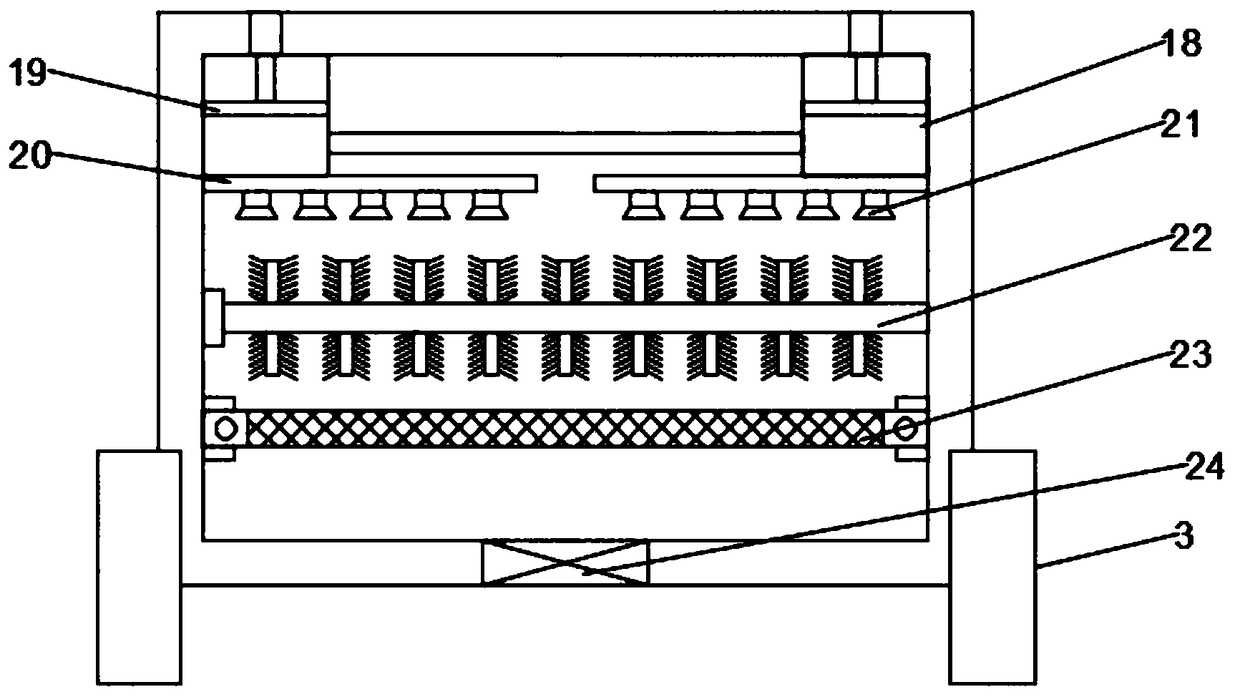

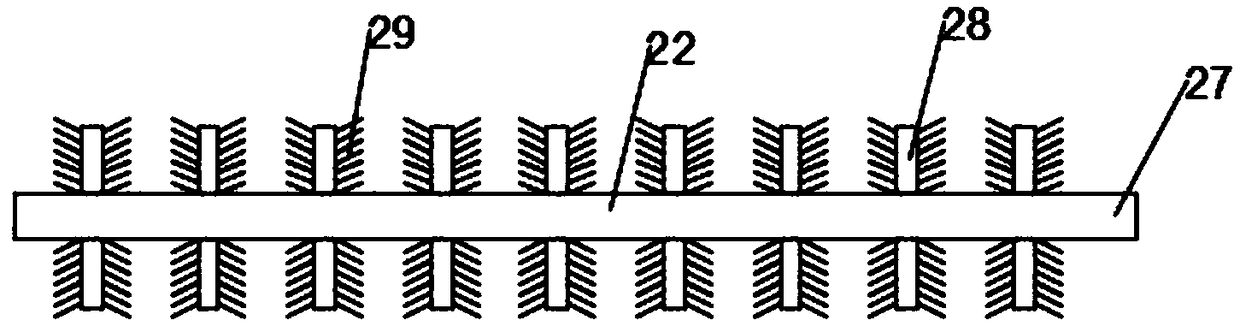

[0020] See Figure 1~3 In the embodiment of the present invention, a peanut cleaning equipment for food processing includes a support frame 1, a base 2, a vertical limit guide 3, a cleaning box 5, a working motor 6 and a cleaning assembly 22, the support frame 1 A welding base 2 is fixed at the bottom. A cleaning box 5 is arranged above the base 2, and a cleaning assembly 22 is arranged inside the cleaning box 5. The cleaning assembly 22 includes a cleaning shaft 27, a stirring blade 28 and a cleaning brush 29. The cleaning box 5 The two side walls are slidably connected to the vertical limit guide 3, the vertical limit guide 3 is fixedly welded to the upper surface of the base 2, and the vertical limit guide 3 can be set to the cleaning box 5 To limit the position, a telescopic rod 4 is arranged between the vertical limit guide rails 3, and both ends of the telescopic rod 4 are fixed and hinged on the upper surface of the base 2 and the lower surface of the cleaning box 5. The...

Embodiment 2

[0026] Such as Figure 4 As shown, in this embodiment, the upper end of the second hinge rod 16 is hinged to the connecting crossbar 7; other structures are the same as in Embodiment 1. The second hinge rod 16 and the connecting crossbar 7 can also be hingedly arranged The intermittent release of the clean water in the clean water compression release box 18 is realized, and the peanuts can be cleaned quickly and efficiently.

[0027] The working principle of the present invention is: peanuts are put in from the rear door (not shown in the figure) of the cleaning box 5, the working motor 6 is started, and the working motor 6 starts forward rotation, which can drive the worm 8 and the first A gear 10 rotates, and the rotation of the first gear 10 drives the first rack 11 to move vertically upward along the guide block 12, so that the guide block 12 drives the cleaning box 5 along the vertical limit. The vertical slide of the position guide rail 3 helps to realize the cleaning of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com