Processing method for tobacco filling materials

A filler and tobacco technology, which is applied in the field of tobacco, can solve the problems that ordinary equipment cannot cut shreds and add flavoring agents, the output of shredded tobacco products is low, the quality effect is low, and the spraying of flavoring agents is uneven, so as to improve the flavoring effect. The effect of practical performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

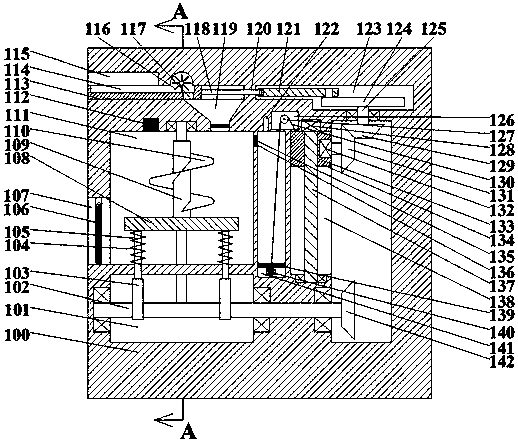

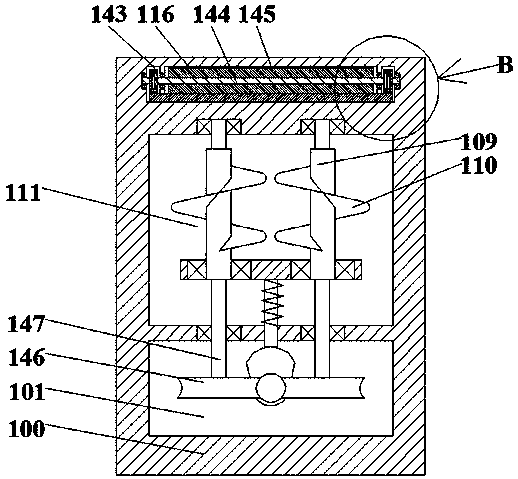

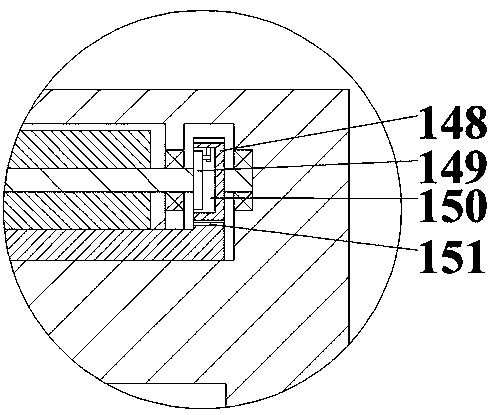

[0018] Such as Figure 1-Figure 3As shown, the tobacco filler processing equipment of the present invention includes a body 100, a first cavity 111 disposed in the body 100 and a second cavity 152 disposed in the body 100, the first cavity A third cavity 101 is arranged in the bottom wall of a cavity 111, and a first sliding block 108 that can move up and down is arranged in the first cavity 111, and left and right symmetrical fixed installations are arranged on the bottom wall of the first sliding block 108. The first guide bar 105 extending downwards, the extension end of the bottom of the first guide bar 105 penetrates the bottom wall of the first cavity 111 and extends into the third cavity 101, and the bottom of the first slide block 108 Between the end surface and the bottom wall of the first cavity 101, there is elastically arranged a first pressure spring 104 surrounding the first guide rod 105, and a front and rear symmetrical rotating rod is rotatably arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com