Leather shoe shaping machine with shoe poLish appLying mechanism

A molding machine and shoe polish technology, applied in shoemaking machinery, footwear, clothing, etc., can solve the problems of shoe polish protection, difficult to fix and apply shoes, etc., and achieve high practical value, high efficiency, improve quality and production level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

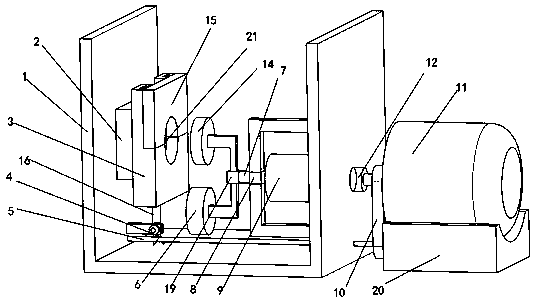

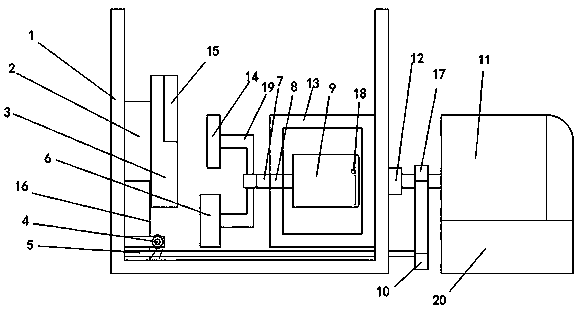

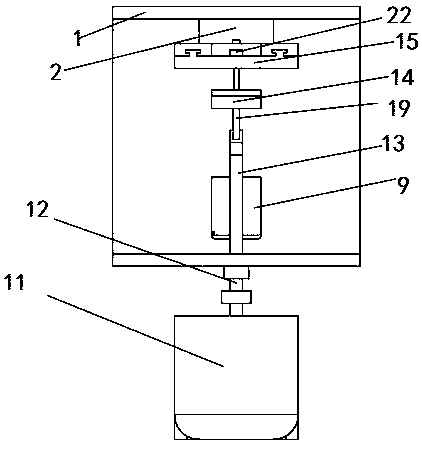

[0024] A leather shoe forming machine with a shoe polish smearing mechanism, comprising a machine base 1 and steel wires 16, a support platform 2 is provided on the inner wall on the left side of the machine base 1, a fixed workbench 3 is provided on the right side of the support platform 2, and the support platform 2 Keep parallel with the table surface of the fixed workbench 3, the upper end of the fixed workbench 3 is provided with a T-shaped track, and the T-shaped track slides in cooperation with the T-shaped groove on the left end surface of the mobile workbench 15, and the mobile workbench 15 is connected with the fixed workbench. Table 3 cooperates to form die cavity 21, and the left side of mobile worktable 15 is provided with boss 22, and described boss 22 is connected with steel wire 16 by spring 23, is provided with opening on the right side of support table 2, and described steel wire 16 is along The opening runs through the support platform 2, and is wound on the ...

Embodiment 2

[0026] A leather shoe forming machine with a shoe polish smearing mechanism, comprising a machine base 1 and steel wires 16, a support platform 2 is provided on the inner wall on the left side of the machine base 1, a fixed workbench 3 is provided on the right side of the support platform 2, and the support platform 2 Keep parallel with the table surface of the fixed workbench 3, the upper end of the fixed workbench 3 is provided with a T-shaped track, and the T-shaped track slides in cooperation with the T-shaped groove on the left end surface of the mobile workbench 15, and the mobile workbench 15 is connected with the fixed workbench. Table 3 cooperates to form die cavity 21, and the left side of mobile worktable 15 is provided with boss 22, and described boss 22 is connected with steel wire 16 by spring 23, is provided with opening on the right side of support table 2, and described steel wire 16 is along The opening runs through the support platform 2, and is wound on the ...

Embodiment 3

[0029]A leather shoe forming machine with a shoe polish smearing mechanism, comprising a machine base 1 and steel wires 16, a support platform 2 is provided on the inner wall on the left side of the machine base 1, a fixed workbench 3 is provided on the right side of the support platform 2, and the support platform 2 Keep parallel with the table surface of the fixed workbench 3, the upper end of the fixed workbench 3 is provided with a T-shaped track, and the T-shaped track slides in cooperation with the T-shaped groove on the left end surface of the mobile workbench 15, and the mobile workbench 15 is connected with the fixed workbench. Table 3 cooperates to form die cavity 21, and the left side of mobile worktable 15 is provided with boss 22, and described boss 22 is connected with steel wire 16 by spring 23, is provided with opening on the right side of support table 2, and described steel wire 16 is along The opening runs through the support platform 2, and is wound on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com