Stirrer device

A stirrer and stirring rod technology, which is applied in the fields of agitator devices and electric agitator devices, can solve the problems of decreased output, poor quality, single function, etc., and achieve the effect of increasing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

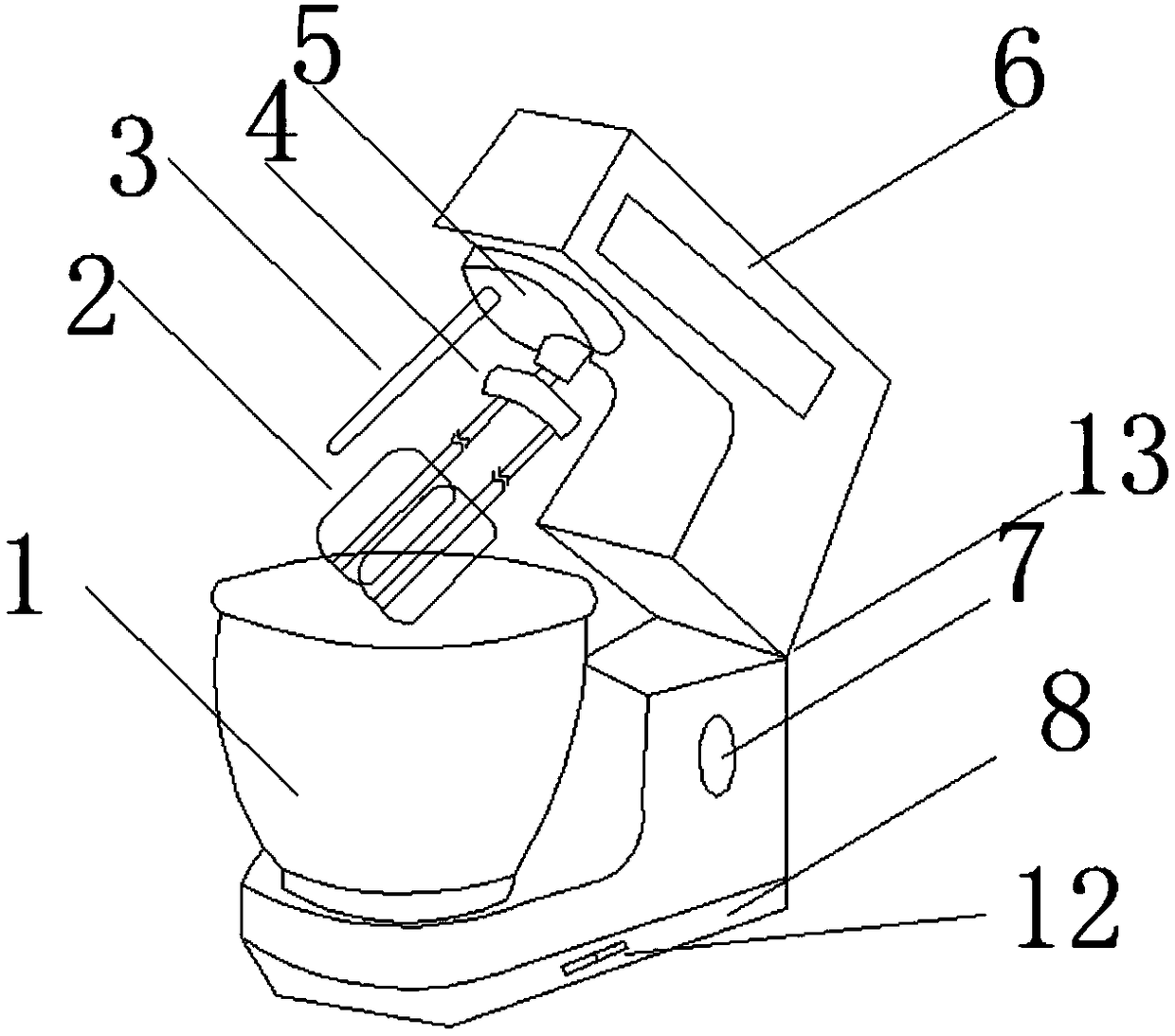

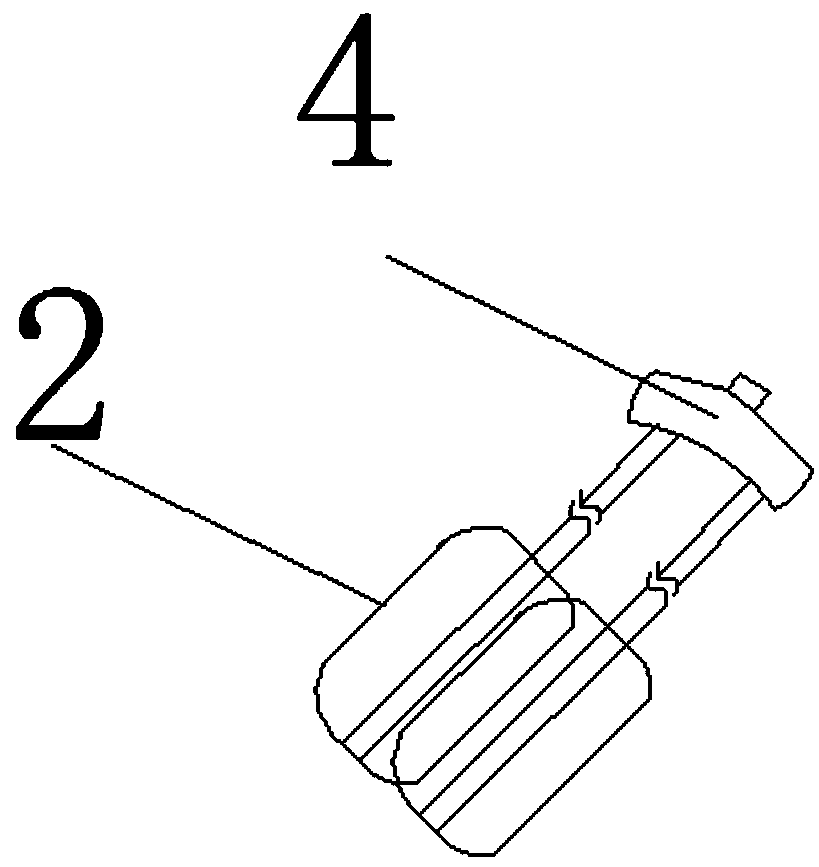

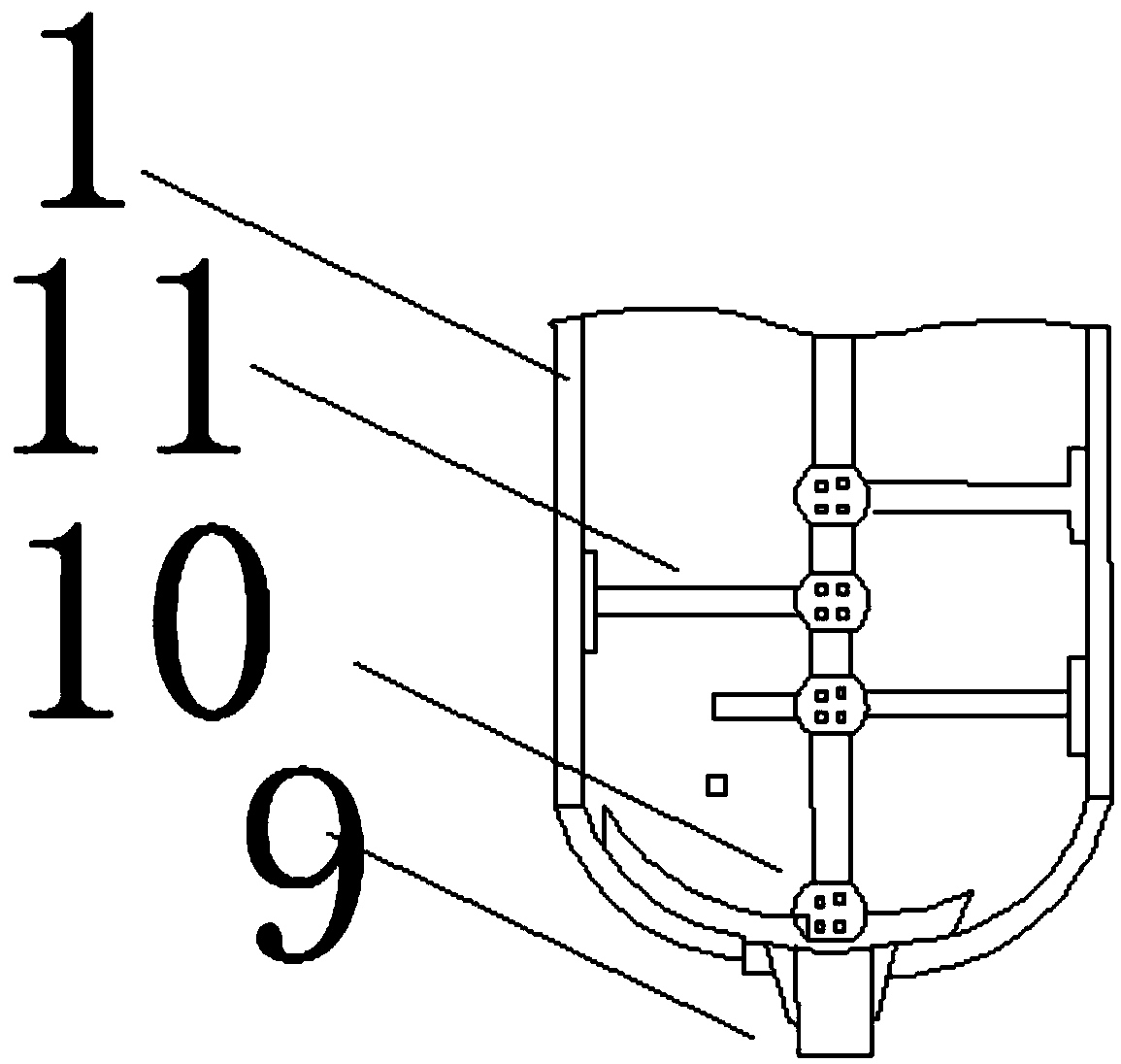

[0014] refer to figure 1 , figure 2 , image 3 and Figure 4 , a stirrer device, characterized in that: its structure includes a liquid container 1, an egg beater 2, a heating rod 3, a rotating chuck 4, a rotating bayonet 5, a handle 6, a temperature adjustment button 7, a base 8, a base Chuck 9, main shaft connection bayonet 10, stirring rod 11, start switch 12, connecting shaft 13; said egg beater 2, stirring rod 11, heating rod 3, handle 6, main shaft connection bayonet 10, liquid container 1 , the base chuck 9, the start switch 12, and the base 8 are sequentially connected to the agitator from top to bottom. fixed on one side, the stirring rod 11 is connected with the rotary chuck 4, the egg-beating rod 2 and the stirring rod 11 are connected with the handle 6 through the rotary chuck 4, and the heating rod 3 is connected with the rotary bayonet 5 The handle 6 is connected to the base 8 through a connecting shaft 13 . The stirring rod 11 is fixed to the stirring rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com