Hydraulic double-cylinder corner breaking shear expander and working method thereof

A hydraulic cylinder and corner technology, which is applied in the field of hydraulic double-cylinder corner breakaway shear expanders, can solve the problems of difficult operation, weak adaptability, and small working radius, and achieve high operational reliability, improved applicability, and easy portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

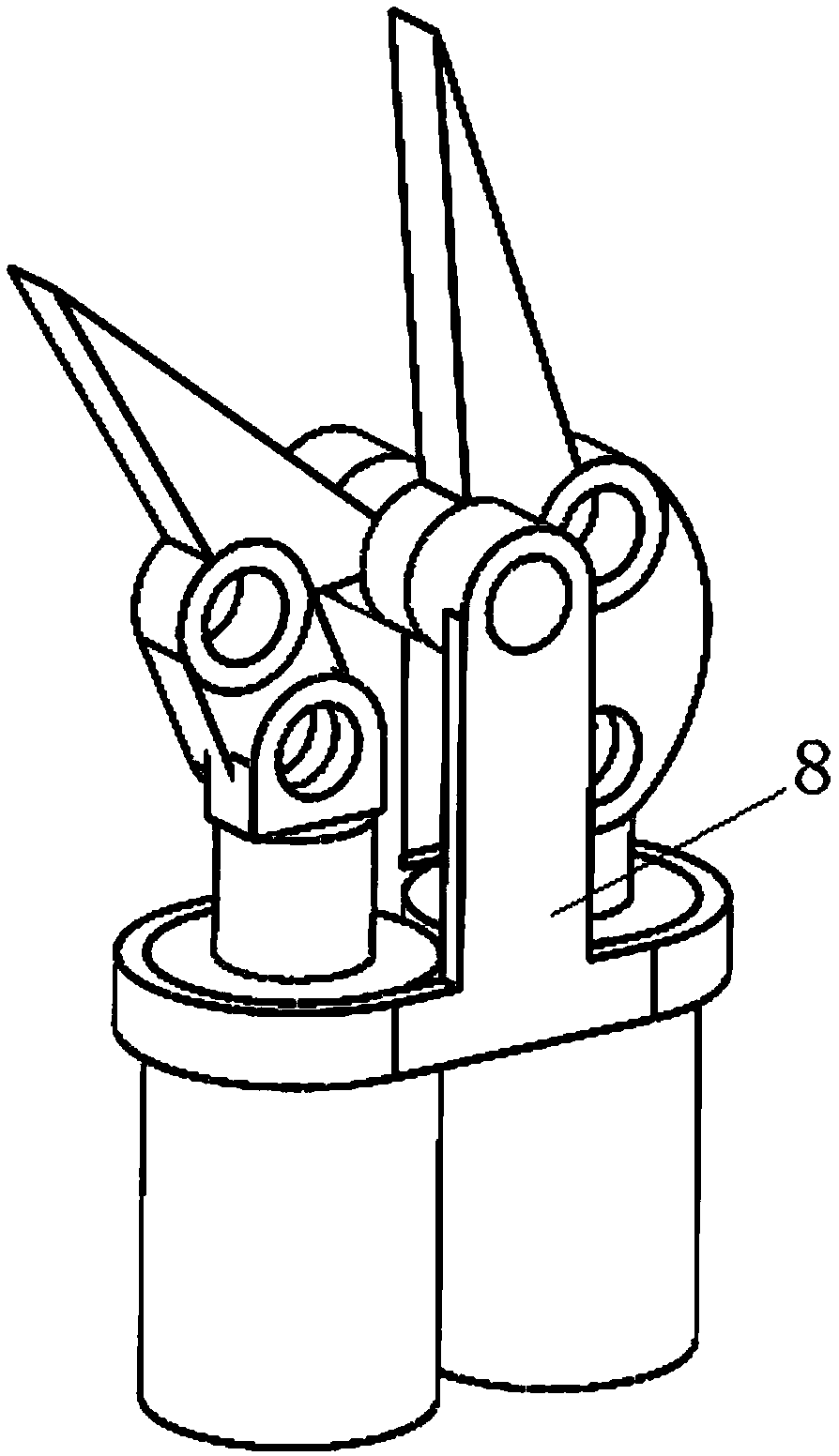

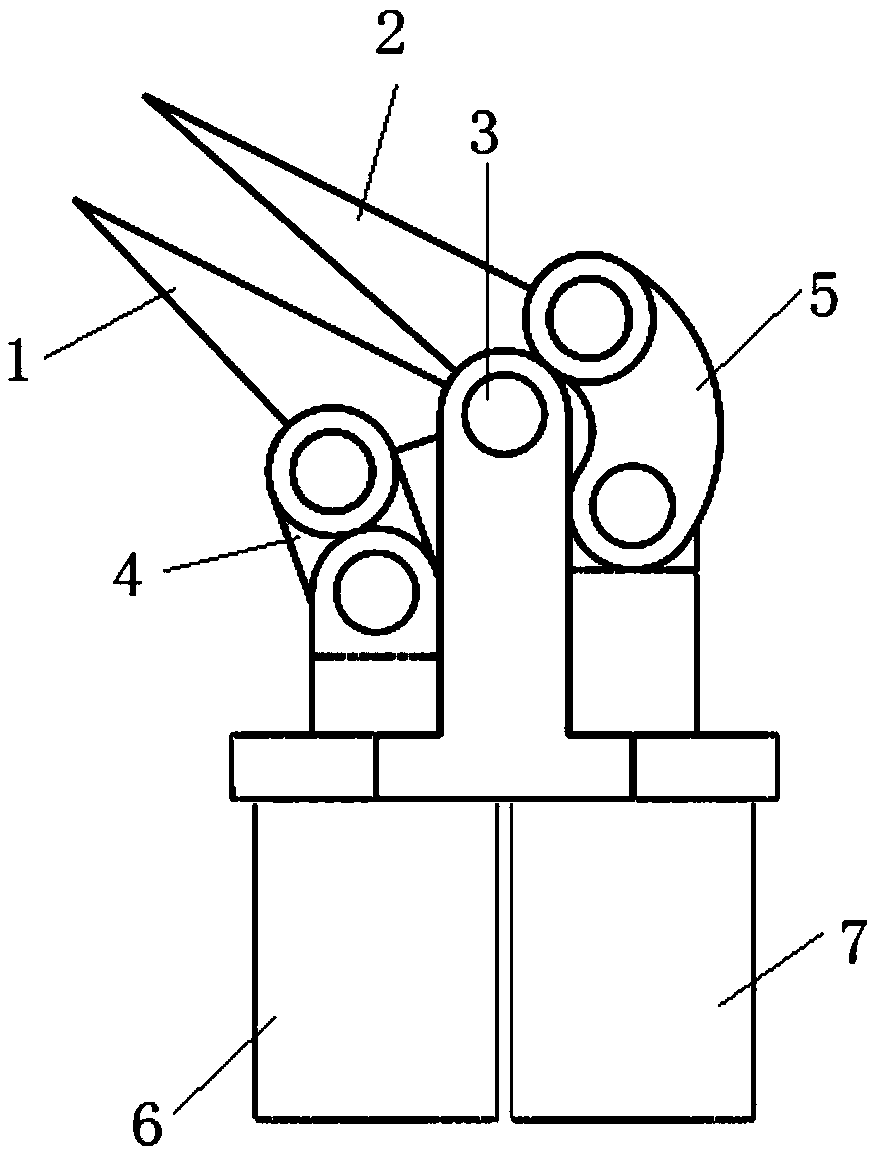

[0026] see Figure 1-7 , a kind of hydraulic double-cylinder breakable corner shearing expander, comprising: inner tool pliers 1, outer tool pliers 2, both of which are hinged on the rotating shaft 3 at the same time; inner hydraulic cylinder 6, outer hydraulic cylinder 7; inner hydraulic cylinder pressure relief When the upper end of the ejector rod shrinks to the lowest plane a, it is lower than the b plane where the upper end of the ejector rod shrinks to the lowest point when the outer hydraulic cylinder is released; straight connecting rod 4, curved connecting rod 5; the upper end of straight connecting rod 4 and the inner tool clamp 1 is hinged, the lower end is hinged with the ejector rod of the inner hydraulic cylinder; the upper end of the curved connecting rod 5 is hinged with the outer tool tongs 2, and the lower end is hinged with the ejector rod of the outer hydraulic cylinder; the inner hydraulic cylinder 6 is depressurized, and the ejector rod of the outer hydrau...

Embodiment 2

[0034] The structure of the hydraulic double-cylinder breakable shear expander is the same as that of the embodiment.

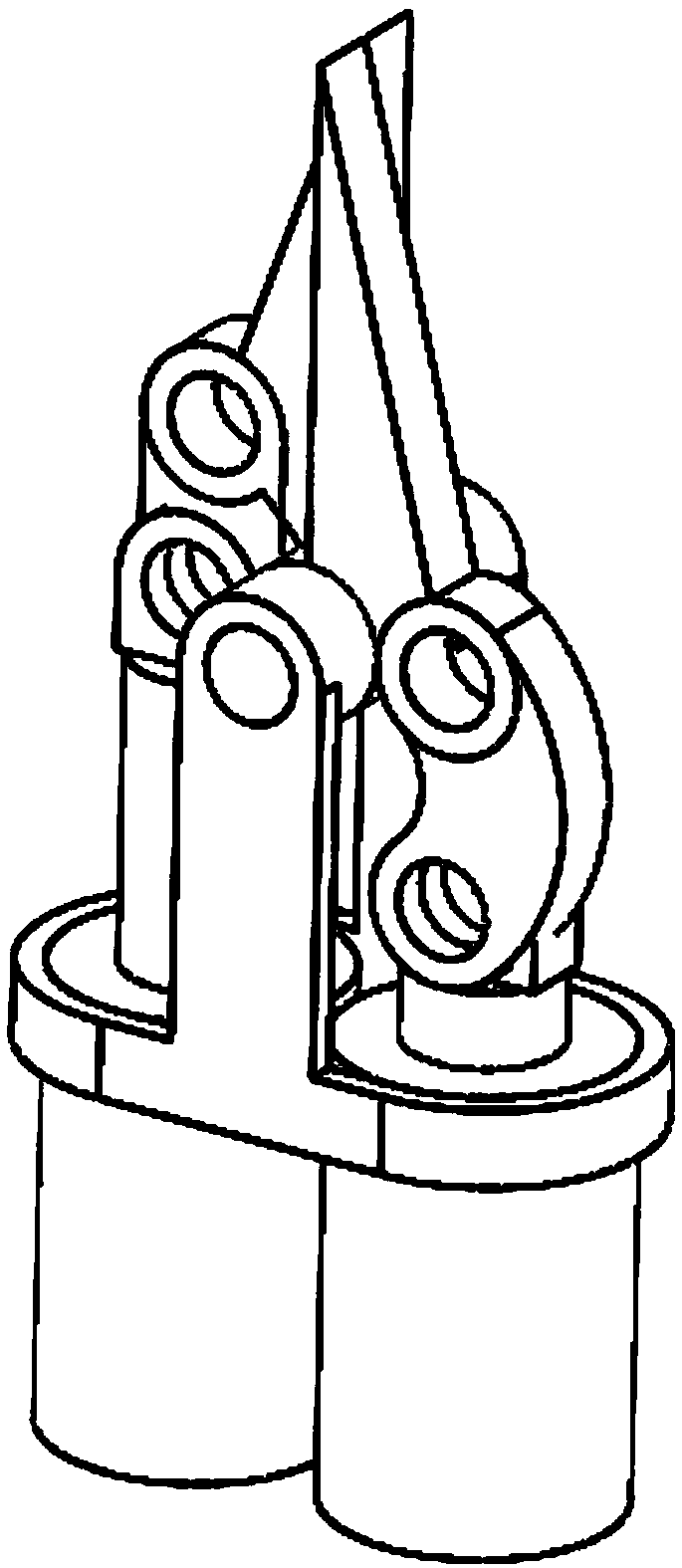

[0035] see Figure 5 , the inner hydraulic cylinder 6 releases pressure, and when the ejector pin of the outer hydraulic cylinder 7 travels to the maximum stroke, the inner tool clamp 1 and the outer tool clamp 2 are closed and rotated 90° to the inside at the same time. Then, a pair of tool pliers is simultaneously stretched into the part to be expanded; the inner hydraulic cylinder 6 and the outer hydraulic cylinder 7 are started simultaneously to drive the pair of tool pliers to rotate in reverse to implement expansion.

Embodiment 3

[0037] The structure of the hydraulic double-cylinder breakable shear expander is the same as that of the embodiment.

[0038] Outer hydraulic cylinder 7 releases pressure, and when inner hydraulic cylinder 6 ejector rods travel to the maximum stroke, inner tool tongs are in an upright position, corresponding to the position of the object to be cut; then, outer hydraulic cylinder 7 drives curved connecting rod 5 to drive The outside tool pliers 2 rotate inwardly around the axis of rotation 3 and implement shearing, such as Image 6 shown.

[0039] The left and right tongs of the hydraulic double-cylinder corner breakable shear expander of the present invention can realize a 0-90° turning angle. Two hydraulic rods respectively drive the left and right tool tongs to realize the opening and closing of the tool tongs; and when the left tongs turn to the limit state, the working pressure can be maintained; when the left and right tongs rotate to a certain angle to the left, the le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap