Electric control system and electric control method for integrated pile driver drill pipe

An electrical control system and a technology for a pile driver, which are applied to the automatic control system of drilling, drilling equipment and method, drill pipe, etc., can solve the problem that the connection between the drill pipe and the grouting mechanism is not easy to disassemble and assemble, and the drilling cannot be carried out in time. Perfusion operation, low degree of automation and other problems, to achieve the effect of high degree of automation, easy installation and disassembly, and not easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

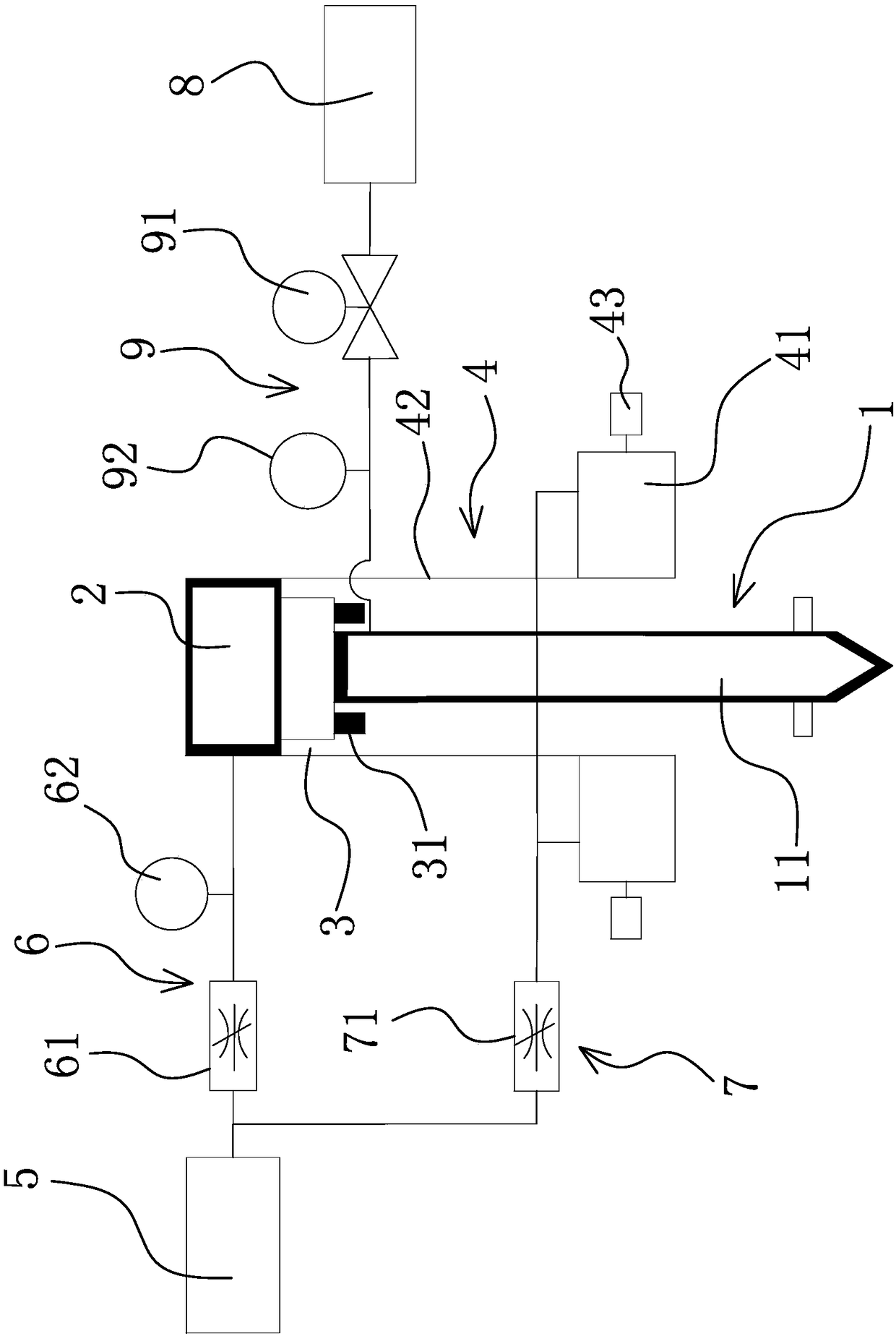

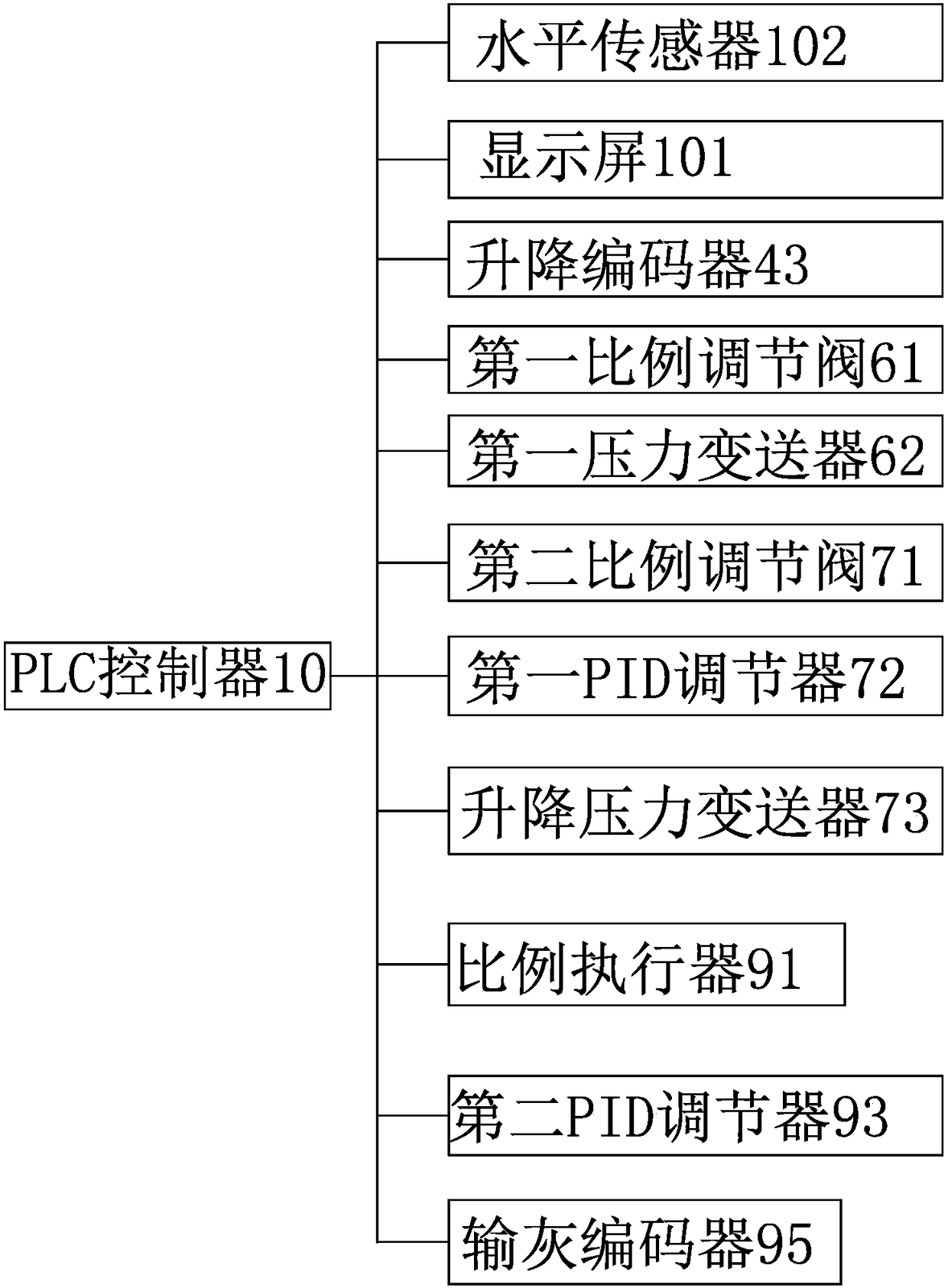

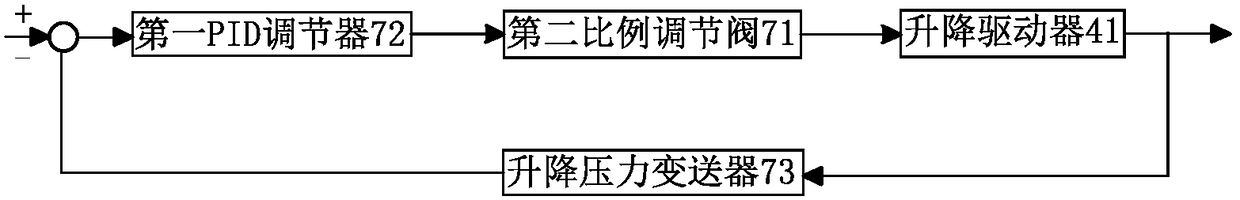

[0028] Such as Figure 1-4 As shown, the drill rod electrical control system of the integrated pile driver includes at least one drill rod assembly 1 with a plurality of drill rod bodies 11. The drill rod assembly 1 is connected with a power head 2 capable of driving the drill rod body 11 to rotate in a circumferential direction. The drill rod assembly 1 is provided with a disassembly and assembly drill rod device 3 capable of docking or separating the power head 2 and the drill rod assembly 1 and having a disassembly and assembly driver 31. The power head 2 is connected to drive the power head 2 to move up and down in the vertical direction. And there is a drill pipe lifting mechanism 4 with a number of lifting drives 41. The power head 2, the disassembly drive 31 and the lifting drive 41 are all connected to a power source 5, and a first power adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com