Glass aspherical lens manufacturing equipment for precise mold pressing

A technology for manufacturing equipment and aspheric surfaces, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as high manufacturing costs, glass lens errors, waste of resources, etc., to reduce manual operations, stabilize processing and manufacturing, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

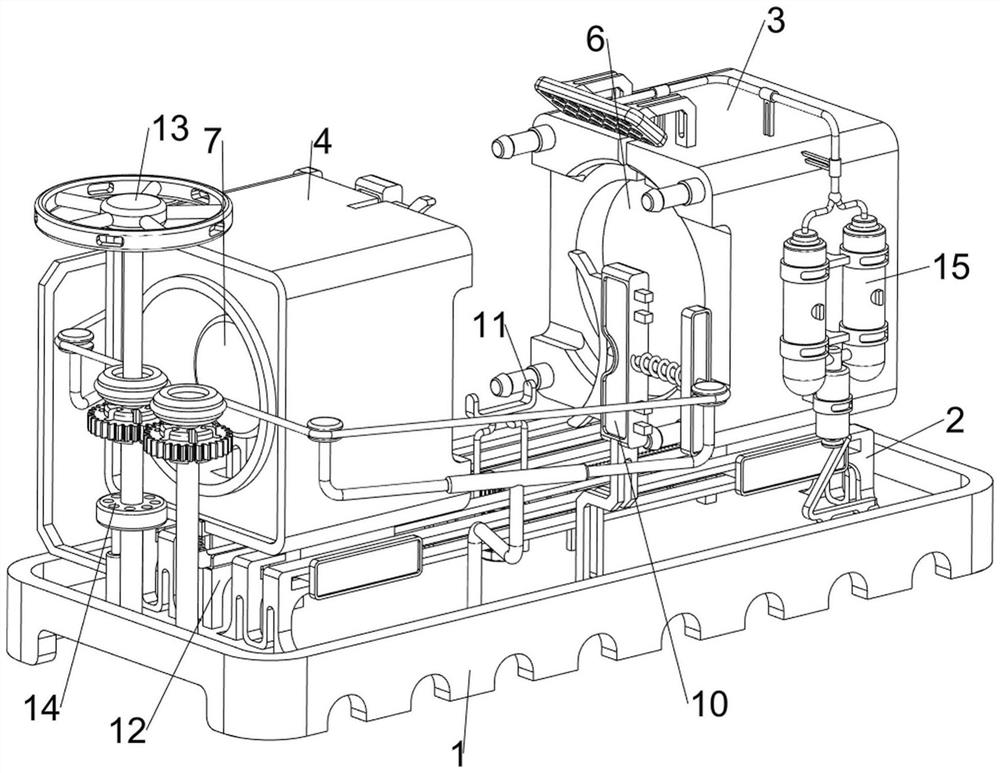

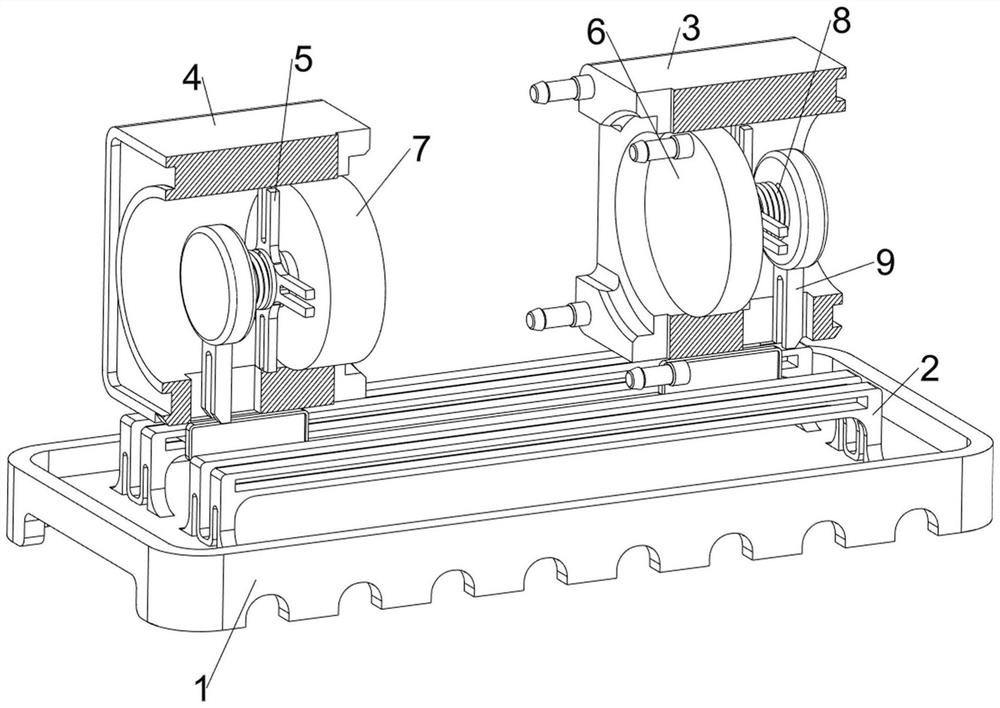

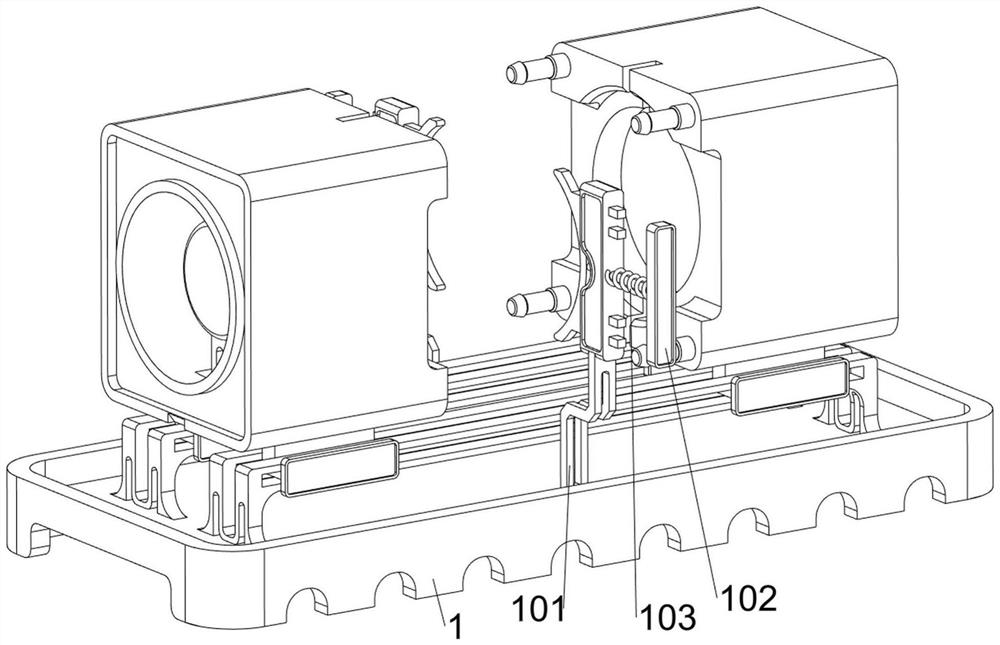

[0090] A precision molded glass aspheric lens manufacturing equipment such as Figure 1-Figure 6 As shown, it includes a bottom plate 1, a first support frame 2, a first sliding module 3, a second sliding module 4, a first fixed block 5, a first sliding mold 6, a second sliding mold 7, a first return spring 8, The first connecting block 9, the clamping mechanism 10 and the placement mechanism 11, the first supporting frame 2 is provided on the front and rear sides of the top of the bottom plate 1, and the first sliding module 3 is slidable between the right sides of the two first supporting frames 2 , the second sliding module 4 is slidingly arranged between the left sides of the two first support frames 2, and the first fixing block 5 is arranged inside the first sliding module 3 and the second sliding module 4, and the first fixing block on the right side 5. The left sliding type is provided with a first sliding mold 6. The first sliding mold 6 is slidingly matched with the ...

Embodiment 2

[0097] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12, Figure 13 , Figure 14 and Figure 15 As shown, the transmission mechanism 12 is also included, and the transmission mechanism 12 includes a support plate 121, a second connection block 122, a rack 123, a second wedge block 124, a first connection spring 125, a motor 126 and a first gear 127, and the bottom plate 1 There are support plates 121 on the left and right sides of the top, and a second connecting block 122 is provided on the left and right sides of the top of the bottom plate 1, and a rack is provided between the supporting plate 121 on the same side and the upper part of the second connecting block 122 in a sliding manner 123, two racks 123 outer tops are slidingly provided with a second wedge block 124, the second wedge block 124 on the left side is in contact with the second sliding module 4, and the second wedge block 124 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com