Wet process deironing equipment and method for electrolytic manganese dioxide

A wet method and equipment technology, applied in the field of deep wet iron removal of electrolytic manganese dioxide, can solve the problems of limited iron removal capacity, small operating space, cumbersome operation, etc., and achieve no risk of material blocking and strong coping ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Selection test of magnetic field strength of iron remover

[0055] At normal temperature and pressure, place 300g of the manganese dioxide sample ground by the mill in a beaker, then add 500ml of water to the beaker, and stir for 5 minutes with a mechanical stirrer. At this time, the pH value of the slurry is about 1.6, and the manganese dioxide After stirring with water evenly, put the magnetic bar and move the magnetic bar along all directions of the beaker, so that the magnetic bar can fully contact the manganese dioxide slurry, and the iron in the manganese dioxide slurry can be fully absorbed by the magnetic field of the magnetic bar. Adsorbed on the magnetic rod, the magnetic rod was taken out after 5 minutes, and the manganese dioxide slurry in the beaker after iron removal was dried to measure the iron content. The magnetic rod adopts the NdFeB magnetic rod produced by Foshan Jinchuang Magnetic Equipment Co., Ltd.

[0056] According to laboratory data, iron r...

Embodiment 2

[0061] Selection of magnetic rod and magnetic rod sheath of iron remover

[0062] The invention provides a wet method iron removal equipment, and the magnetic material is neodymium iron boron. The magnetic rod is composed of multi-layer NdFeB, the diameter of NdFeB is Φ25~35mm, and 0.2~2mm iron sheet is installed between each layer of NdFeB as the magnetic material and strengthens the magnetic field strength, with a thickness of 0.4~5mm 304, 316 stainless steel or PVC wrapped fastening.

[0063] The material of the magnetic bar sheath is 304, 316 stainless steel or PVC. The inner diameter of the magnetic bar sheath is 1-6mm larger than the outer diameter of the magnetic bar, and the thickness is 0.4-5mm. The bottom of the magnetic bar is conical or frustum-shaped, and the top is installed according to the size of the sheath Φ30 ~ 40mm installation fixed side.

Embodiment 3

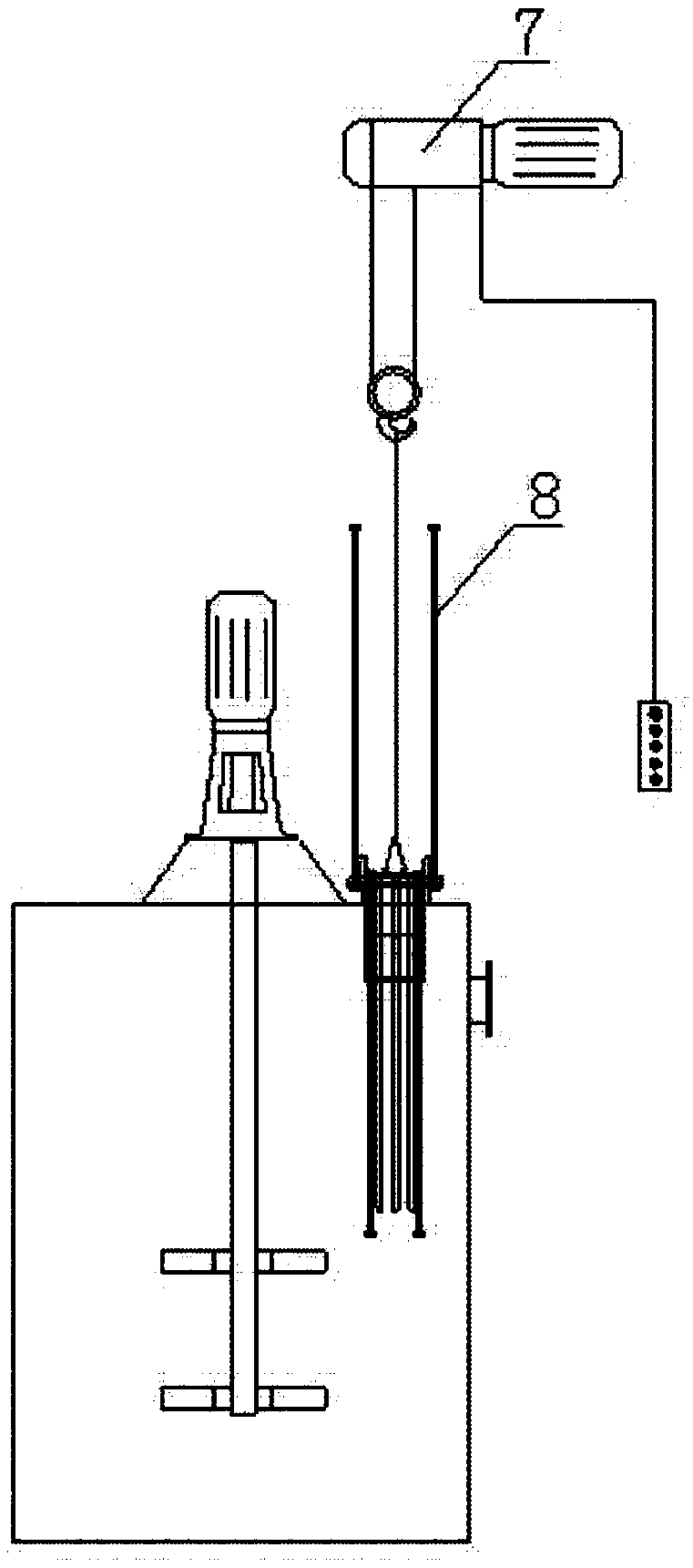

[0065] The iron removal equipment consists of two parts: the iron remover body and the iron removal auxiliary mechanism. The design height of the iron remover body is 1000-1800mm, the length of the magnetic rod is 800-1700mm, and the height of the iron removal operation is 1000-1500mm. The installation or stripping operations are all assisted by lifting devices. The design fully considers the characteristics of equipment installation and operation. The equipment design conforms to the principles of ergonomics, and the operation is simple and convenient.

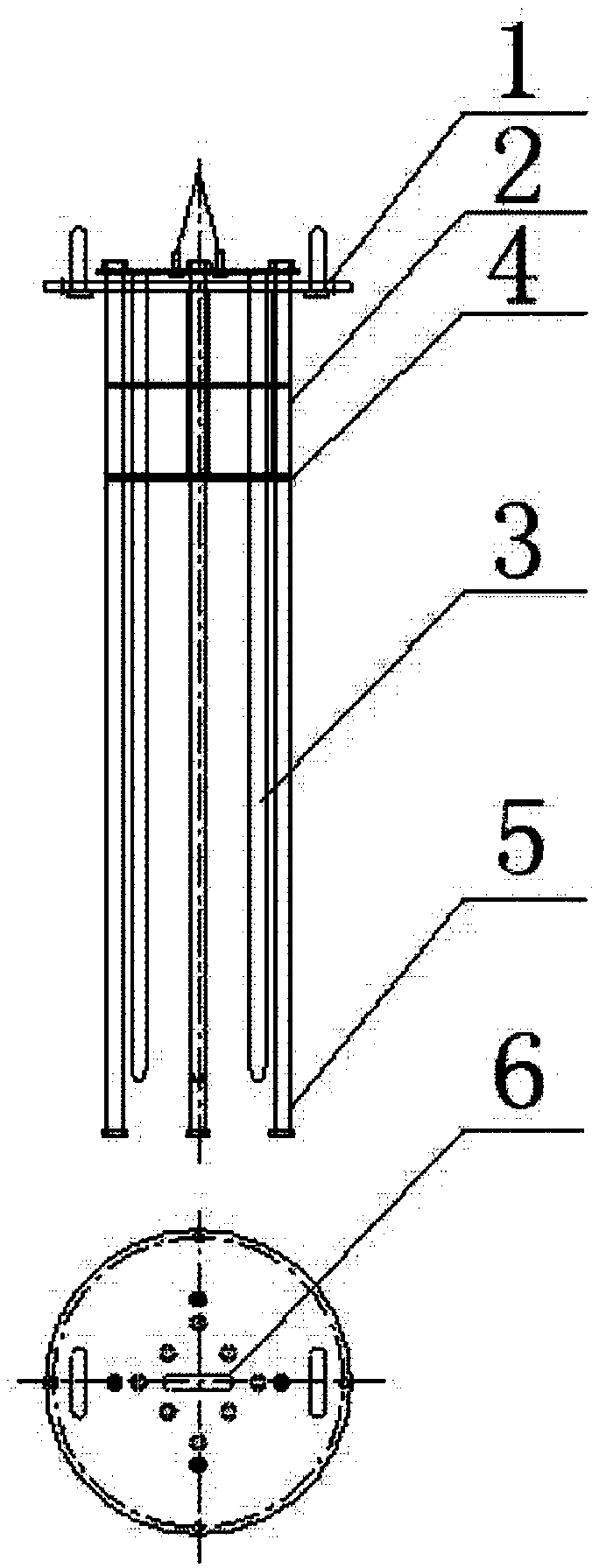

[0066] The main body of the iron remover is composed of static and dynamic parts. The "static" part includes the main mechanism components such as the mounting flange 1, the magnetic rod mounting base 2, and the iron removal plate 4, which realize the installation and fixation of the iron remover and the function of removing the iron adsorbed on the magnetic rod. The "moving" part is composed of magnetic rod, magnetic rod sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com