Automatic feeding device for forging press

A technology for automatic feeding and forging presses, applied in forging/pressing/hammer devices, operating devices, metal processing equipment, etc., can solve problems such as low work efficiency and danger, and achieve improved work efficiency, high utilization value, and The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

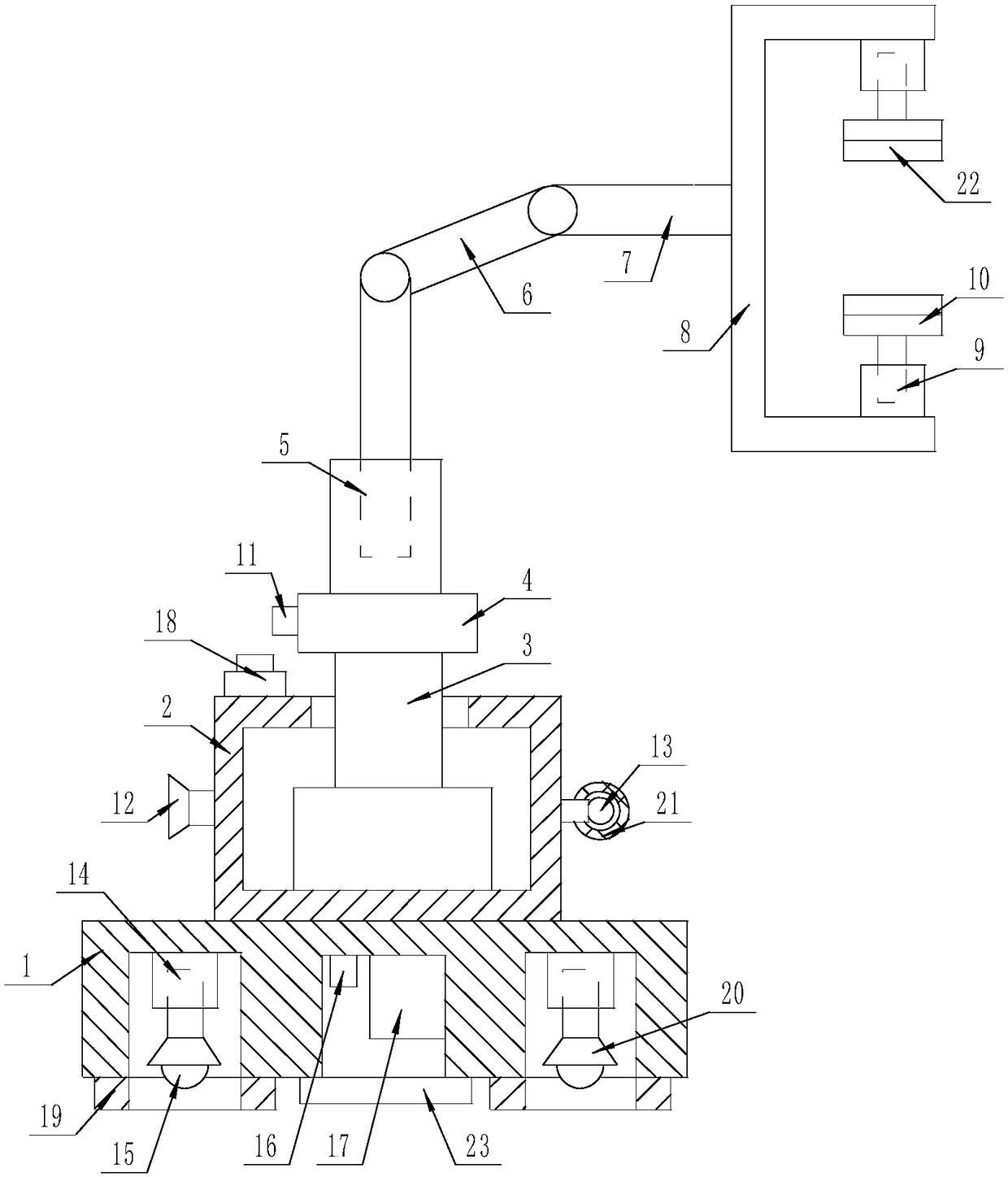

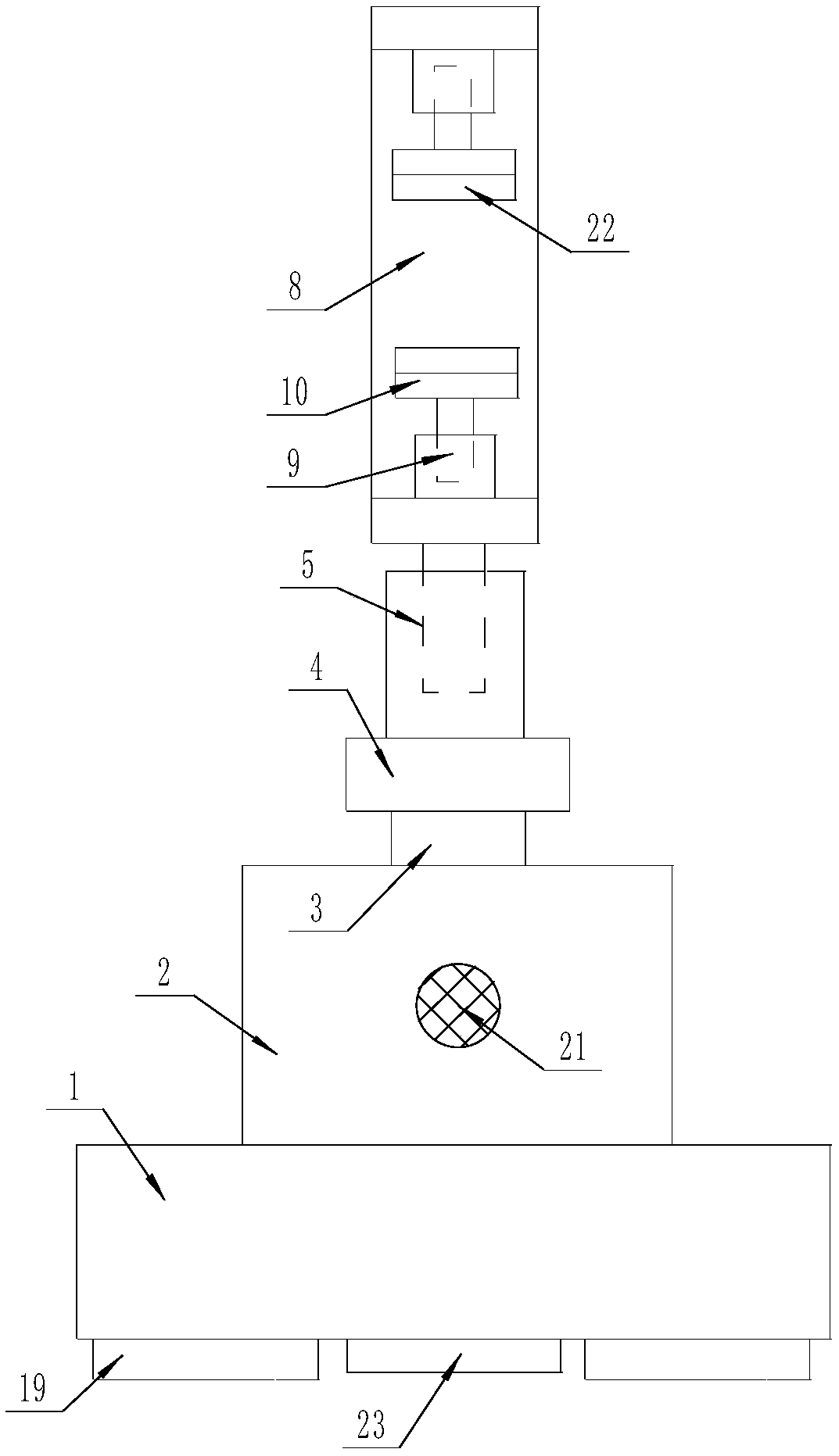

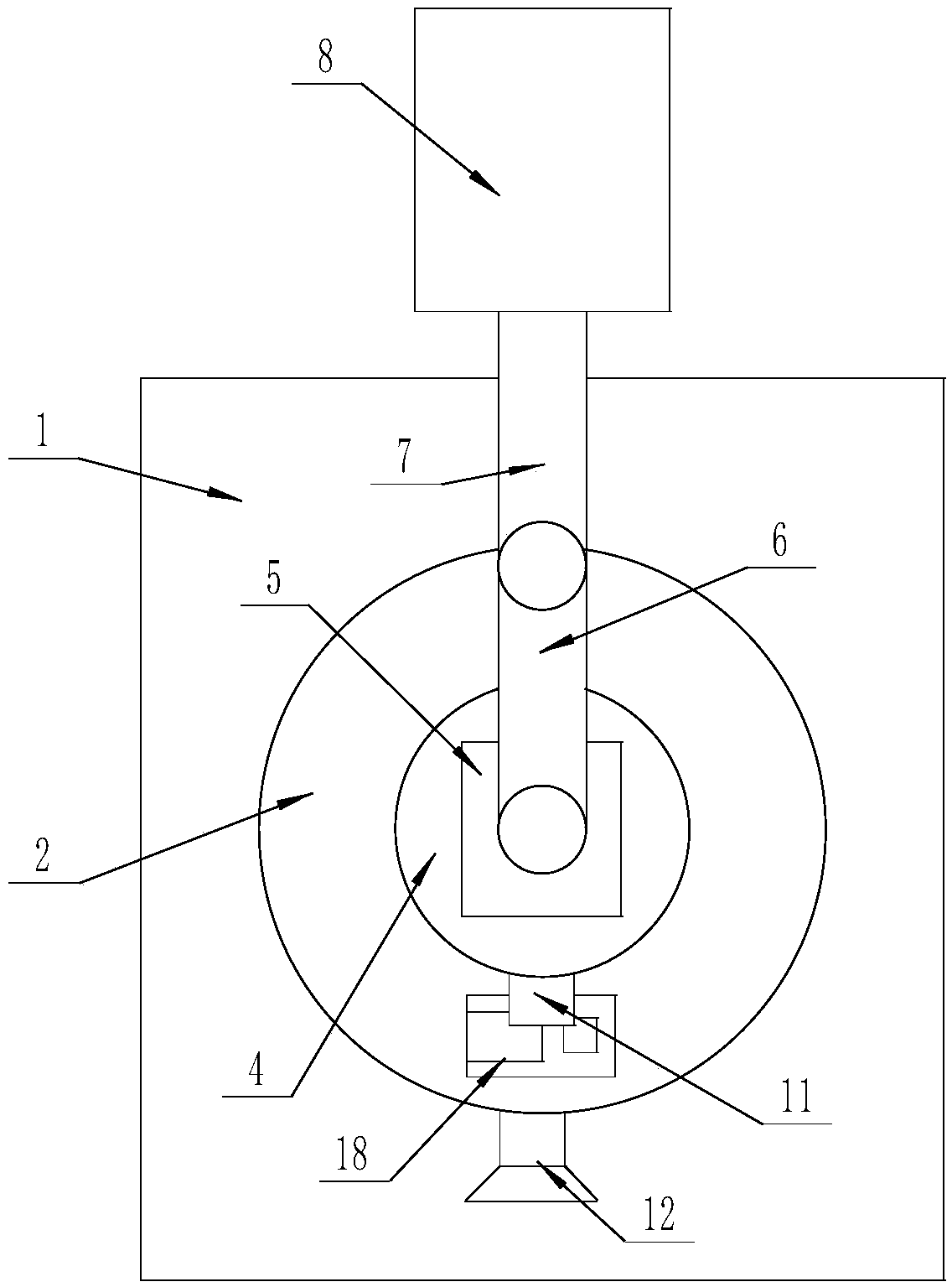

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, an automatic feeding device for a forging press includes a bearing base 1, the upper surface of the bearing base 1 is fixedly connected with a circular motor protection box 2, and the upper surface of the circular motor protection box 2 is processed with a movable opening. The inner and lower surface of the circular motor protection box 2 is fixedly connected with a steering motor 3 whose rotating end is upward, and the rotating end of the steering motor 3 is fixedly connected with a circular carrier plate 4, and the upper surface of the circular carrier plate 4 is fixedly connected with a The hydraulic telescopic rod 5 with the telescopic end upward, the telescopic end of the hydraulic telescopic rod 5 is movably connected to a No. 1 electronically controlled mechanical arm 6, and one end of the No. 1 electronically controlled mechanical arm 6 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com