A welding machine and automatic welding method based on vision positioning

A visual positioning, welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as welding defects, reduce hazards, reduce production costs, and improve welding quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

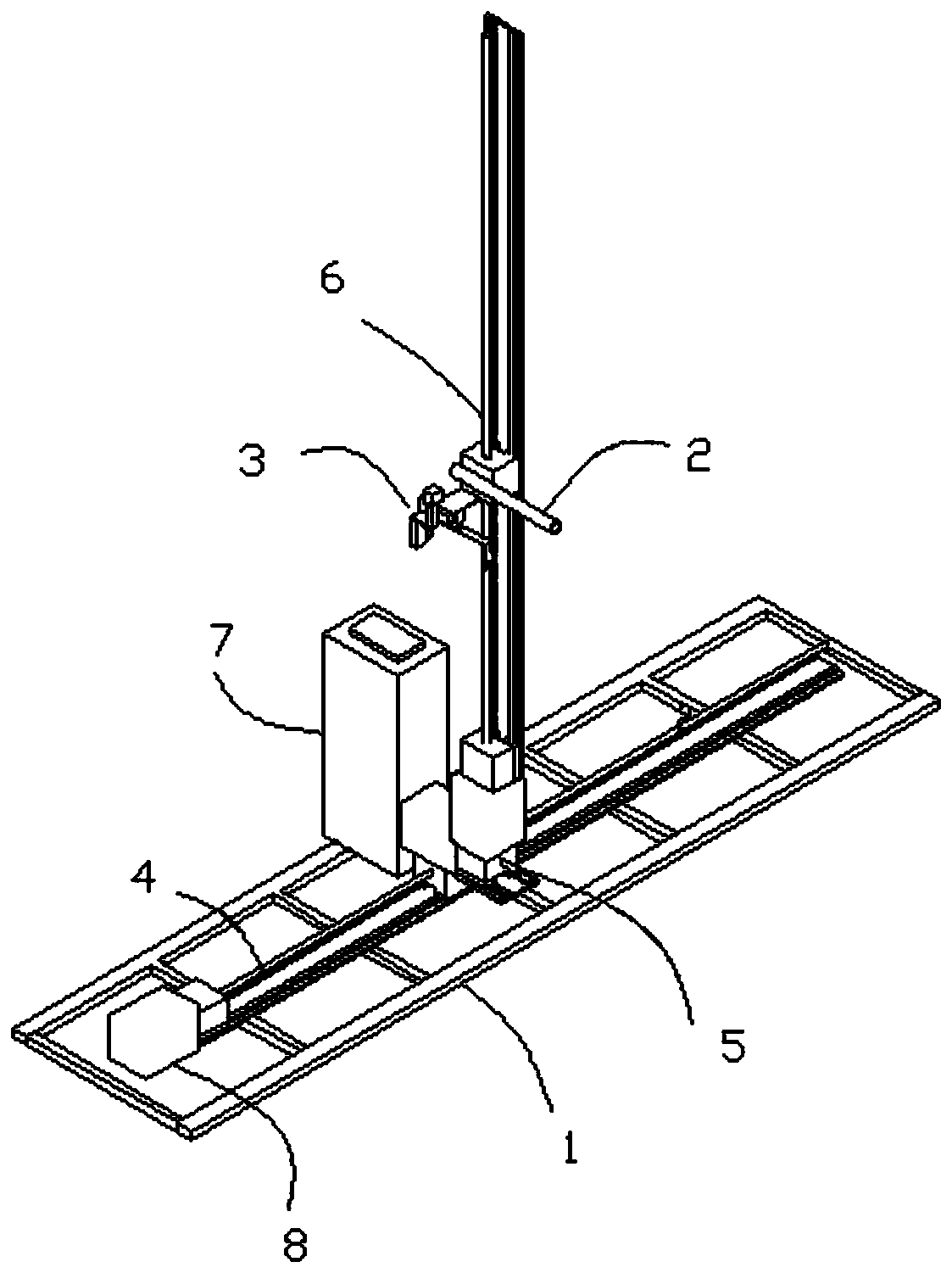

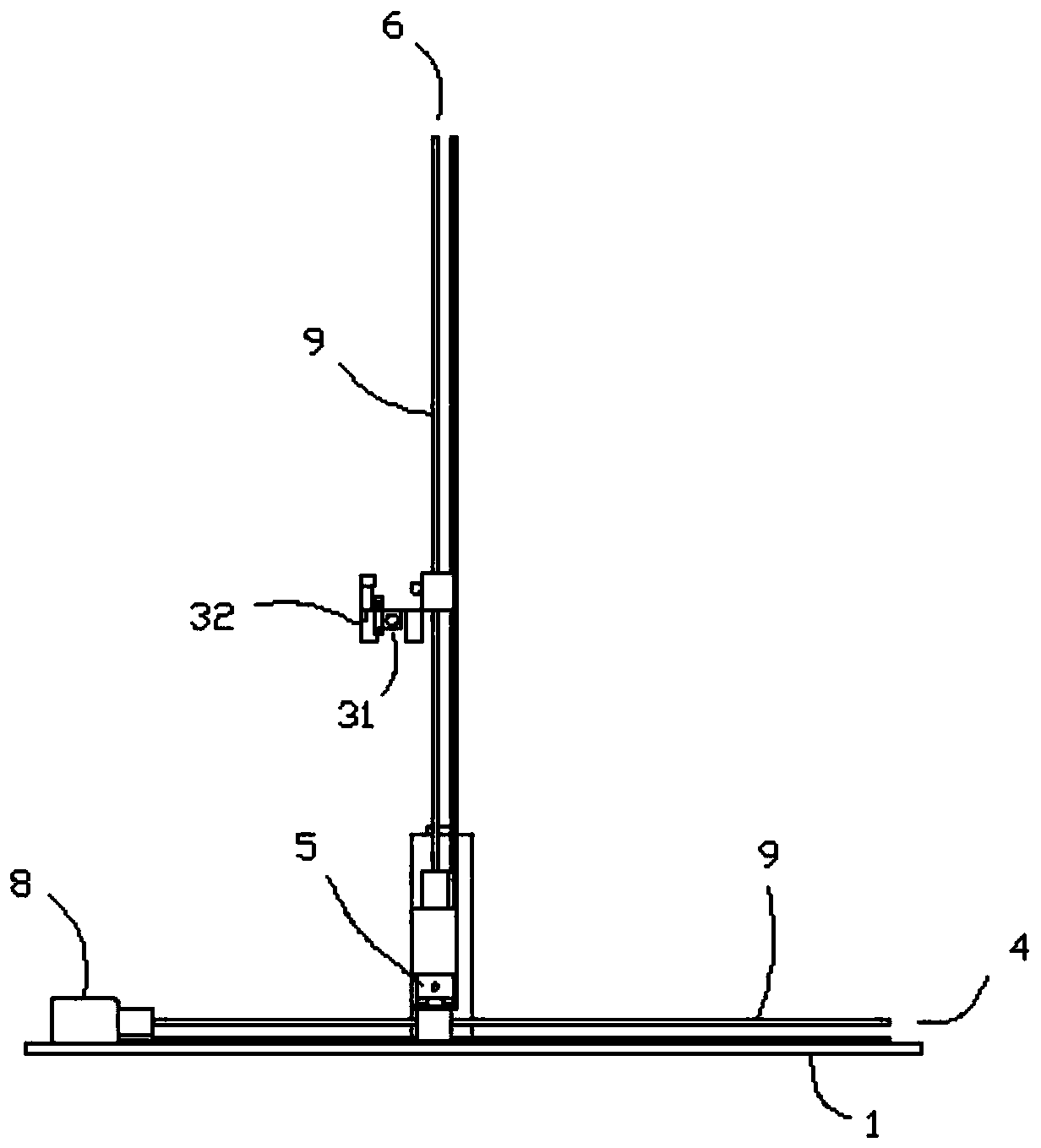

[0039] Such as figure 1 and figure 2 As shown, a welding machine based on vision positioning includes a base 1 , a motion mechanism, a welding torch module 2 and a vision positioning module 3 . The base 1 is used to support other components, and the movement mechanism is installed on the base 1 and connected with the welding torch module 2 for driving the welding torch module 2 to move in front, back, left and right and up and down directions.

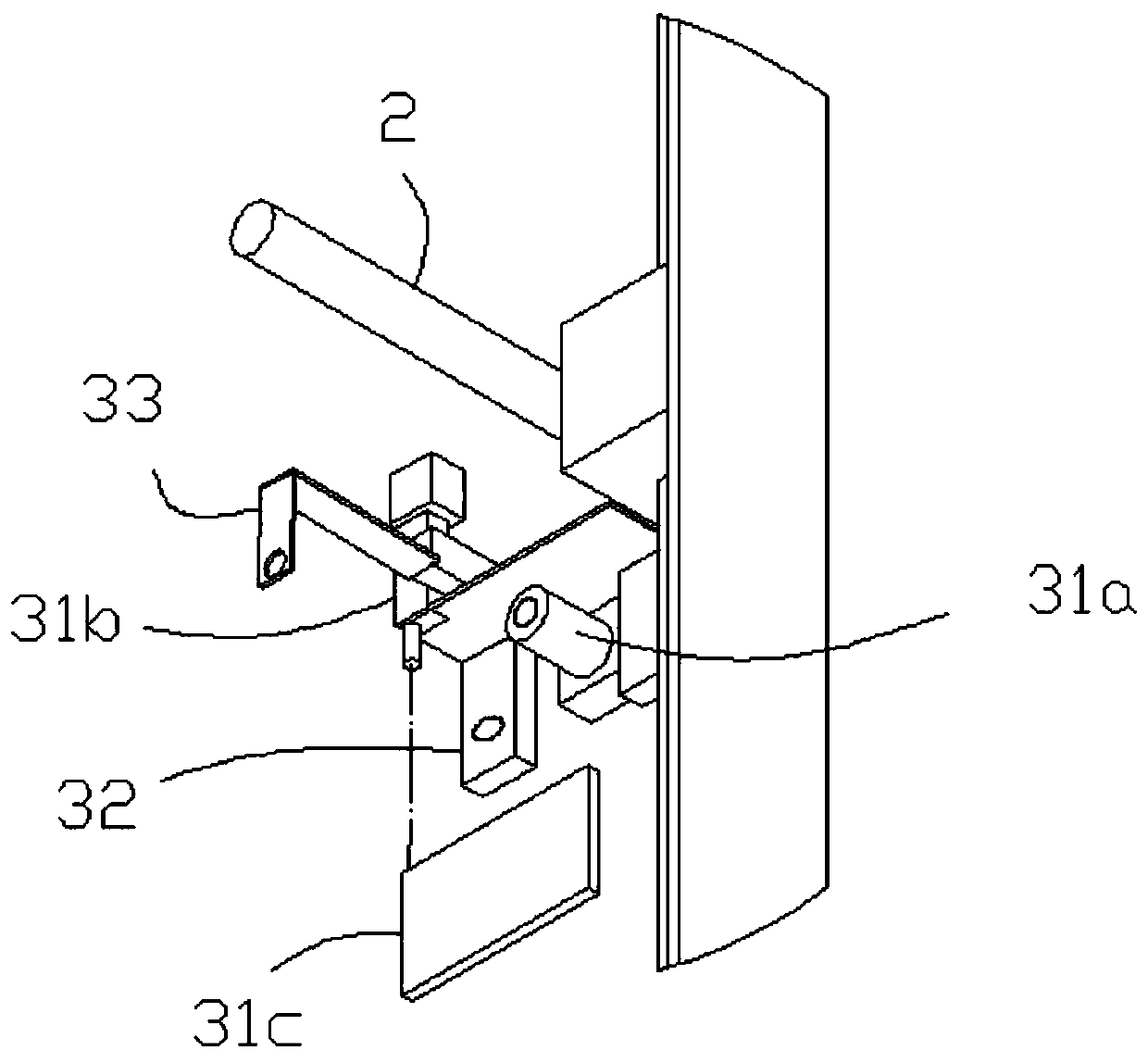

[0040] combine image 3 and Figure 4 As shown, the visual positioning module 3 includes an image acquisition module 31, an illumination module 32, a reference object and an image processing device; the image acquisition module 31 is fixedly connected to the welding torch module 2, and is used to acquire image information of workpieces to be welded; The lighting module 32 co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap