Double-end rapid forming machine and forming method of anisotropic ferrite magnetic shoes

A technology of ferrite magnetism and forming method, applied in the field of magnetic tile manufacturing, can solve the problems of difficulty in improving efficiency, limited pressing time of press and orientation time of magnetic field, uniformity and mutual interference of magnetic field orientation, etc., to achieve the generation efficiency Improve, improve the generation efficiency, improve the effect of magnetization uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

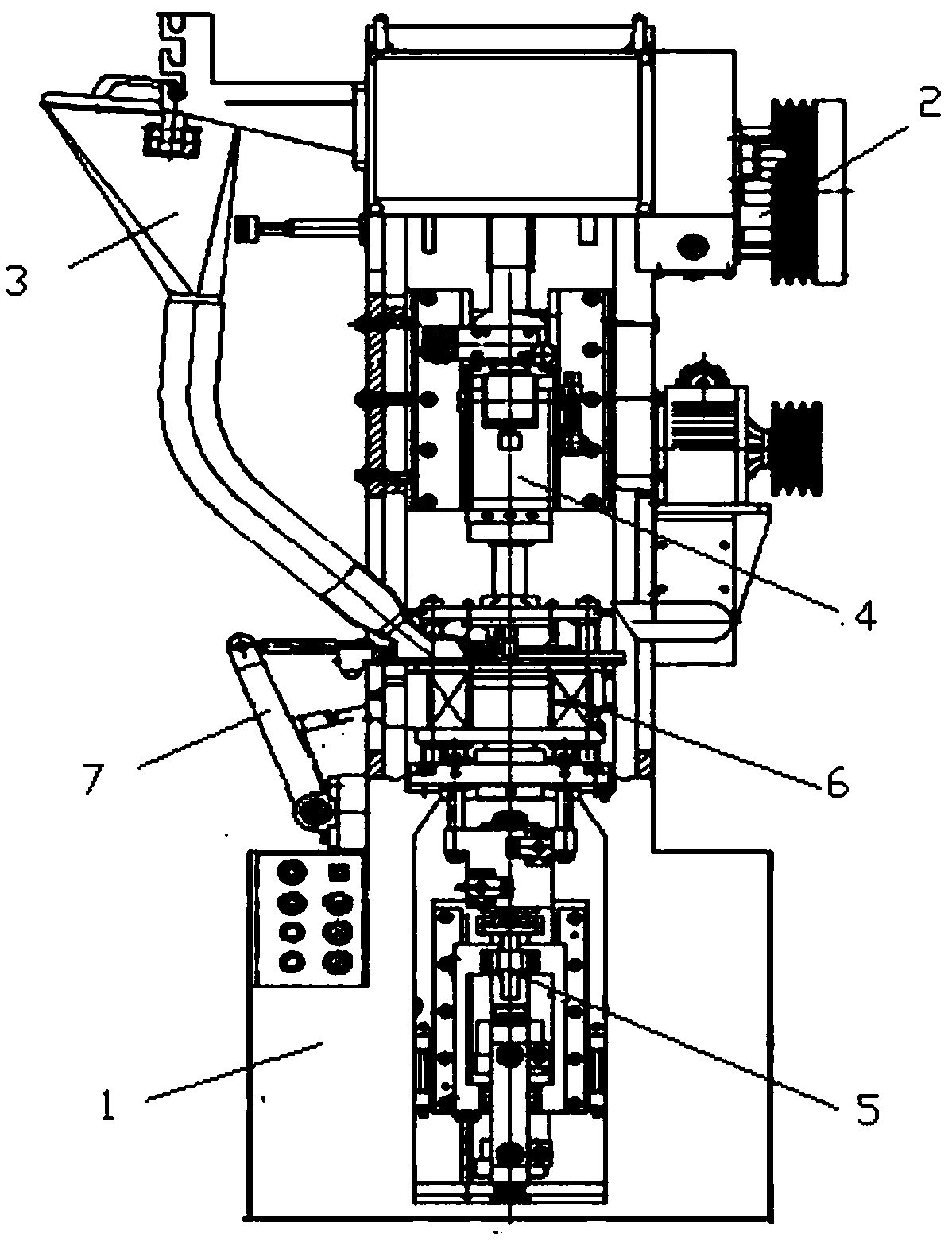

[0034] refer to figure 1 , figure 2 and image 3 , a double-head rapid prototyping machine for heterosexual ferrite magnetic tiles, including a frame 1, a transmission mechanism 2, an automatic feeding mechanism 3, an upper pressing mechanism 4, a lower column mechanism 5, a mold frame mechanism 6 and a mold pushing mechanism 7, the transmission Mechanism 2 provides power for the forming machine and converts the circular motion of the motor into the up and down reciprocating motion of the pressing mechanism.

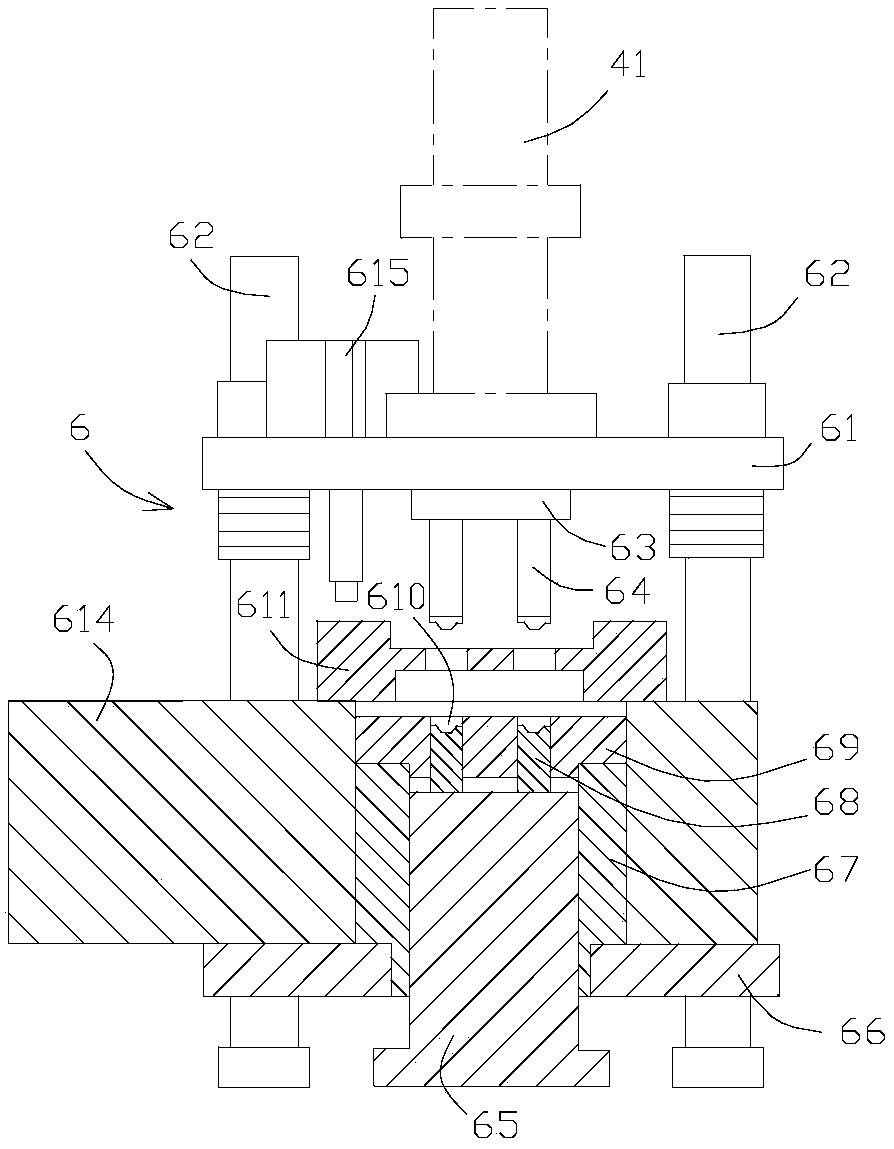

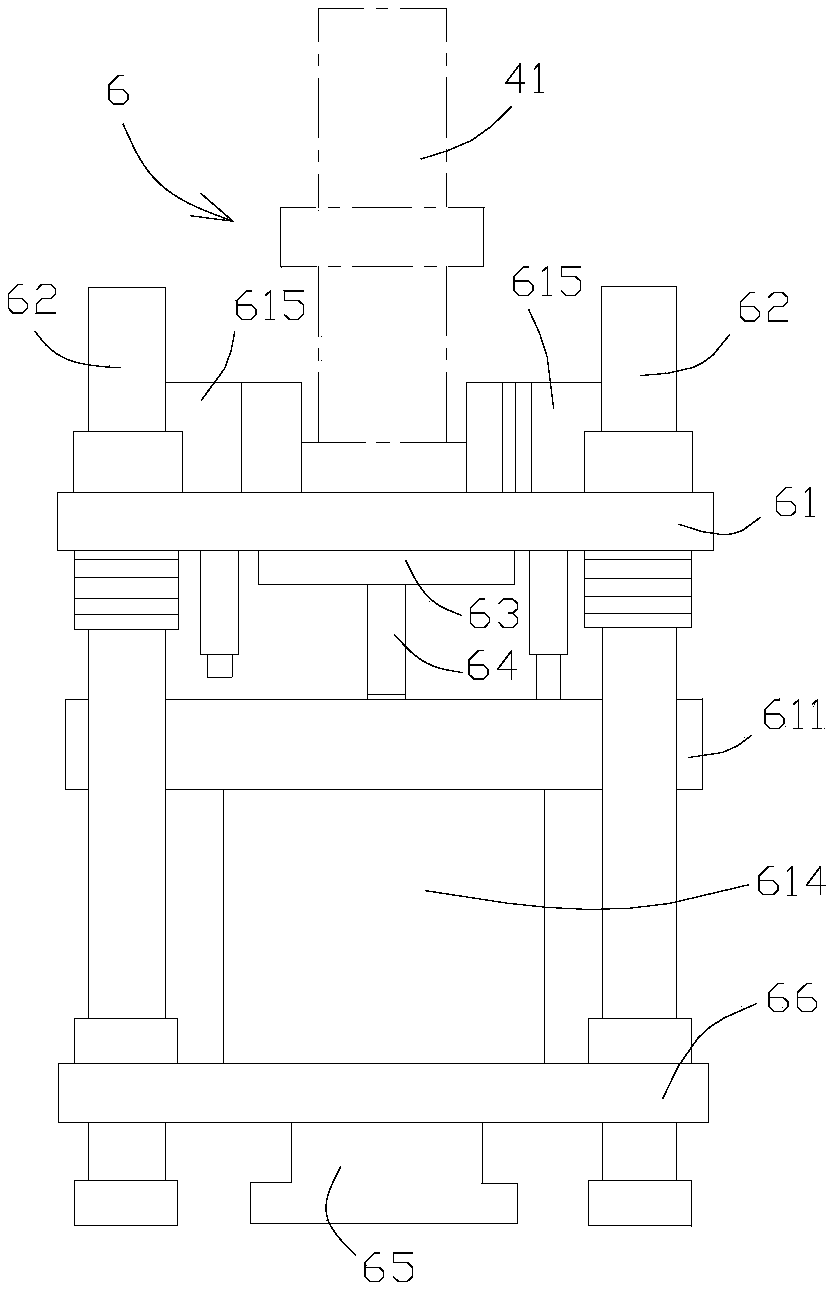

[0035] The mold frame mechanism 6 includes an upper template 61, an upper mold guide rod 62, an upper punch fixing seat 63, an upper punch 64, a middle mold 69, a lower punch 68, a lower punch fixing column 65, a cavity floating plate 66, and a die cavity. Cavity fixing sleeve 67, material box supporting plate 611, wire bag 614 and pre-pressing cylinder 615; Upper template 61, material box supporting plate 611, middle mold 69 and mold cavity floating plate 66 are arran...

Embodiment 2

[0041] A method for forming an anisotropic ferrite magnetic tile using the double-head forming machine of Example 1, including sequentially connected powder filling steps, magnetic field orientation steps, pressing steps, degaussing steps and mold removal steps, and also includes steps in magnetic field orientation A pre-pressing step performed after the step starts. The specific steps are as follows:

[0042] refer to Figure 4 , when the turntable angle is set to 0°, the upper punch is at the lowest position, when the turntable angle is 180°, the upper punch is at the highest position, and when the turntable angle is 350° as the starting point, the turntable rotates clockwise for one cycle, which is a press process.

[0043] When the turntable starts to rotate, the PIC system controls the automatic feeding mechanism 3 to start moving to the mold frame mechanism 6, and the mold box moves to the mold box supporting plate 611 facing the mold cavity 610, and starts to fill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com