A shaft furnace for efficiently controlling the magnetization of iron ore and its roasting method

A technology for magnetization roasting and iron ore, which is applied to the roasting of shaft furnaces and the field of shaft furnaces that efficiently control the magnetization of iron ore, can solve the problems of poor uniformity of ore roasting magnetization, high gas consumption, lump ore sticking, etc. Ore roasting time, increase shaft furnace output, and prevent sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

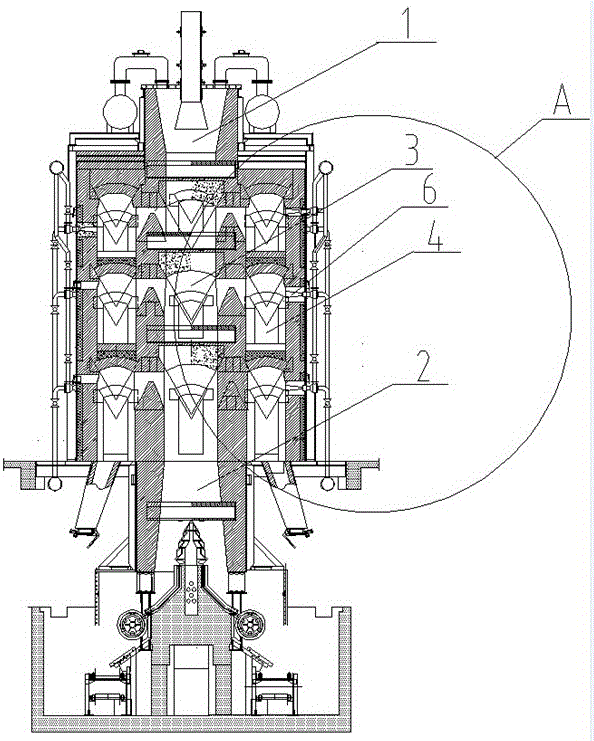

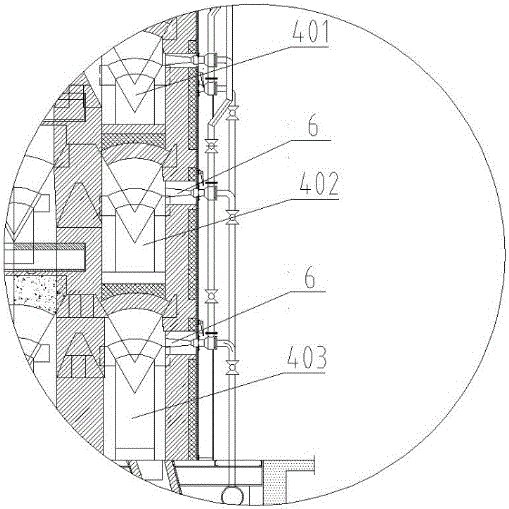

[0021] A shaft furnace for efficiently controlling the magnetization of iron ore, including a feeding system at the upper part of the furnace roof, a furnace body, an ore discharge system at the lower part of the furnace body and a smoke extraction system, wherein the furnace body is divided into a preheating section 1, a heating section and a reduction section 2. The middle of the heating section is the furnace 3, and the two sides of the furnace 3 are the combustion chambers 4. The combustion chambers 4 on each side are vertically divided into three layers. From top to bottom, the first layer of combustion chambers 401, the second layer of combustion chambers 402 and The third layer of combustion chamber 403, the height of the first layer of combustion chamber 401 is 0.713mm, the height of the second layer of combustion chamber 402 is 1.024mm, and the height of the third layer of combustion chamber 403 is 1.406mm. Each combustion chamber is provided with a hot burner 6 .

[...

Embodiment 2

[0024] A shaft furnace for efficiently controlling the magnetization of iron ore, including a feeding system at the upper part of the furnace roof, a furnace body, an ore discharge system at the lower part of the furnace body and a smoke extraction system, wherein the furnace body is divided into a preheating section 1, a heating section and a reduction section 2. The middle of the heating section is the furnace 3, and the two sides of the furnace 3 are the combustion chambers 4. The combustion chambers 4 on each side are vertically divided into three layers. From top to bottom, the first layer of combustion chambers 401, the second layer of combustion chambers 402 and The third layer of combustion chamber 403, the height of the first layer of combustion chamber 401 is 0.813 mm, the height of the second layer of combustion chamber 402 is 1.124 mm, and the height of the third layer of combustion chamber 403 is 1.506 mm. Each combustion chamber is provided with a hot burner 6 . ...

Embodiment 3

[0027] A shaft furnace for efficiently controlling the magnetization of iron ore, including a feeding system at the upper part of the furnace roof, a furnace body, an ore discharge system at the lower part of the furnace body and a smoke extraction system, wherein the furnace body is divided into a preheating section 1, a heating section and a reduction section 2. The middle of the heating section is the furnace 3, and the two sides of the furnace 3 are the combustion chambers 4. The combustion chambers 4 on each side are vertically divided into three layers. From top to bottom, the first layer of combustion chambers 401, the second layer of combustion chambers 402 and The third layer of combustion chamber 403, the height of the first layer of combustion chamber 401 is 0.763mm, the height of the second layer of combustion chamber 402 is 1.074mm, and the height of the third layer of combustion chamber 403 is 1.456mm. Each combustion chamber is provided with a hot burner 6 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com