Heat treatment method and equipment through rotating magnetic field generated from magnetic parts of an apparatus

A heat treatment method and technology of rotating magnetic field, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems such as not meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

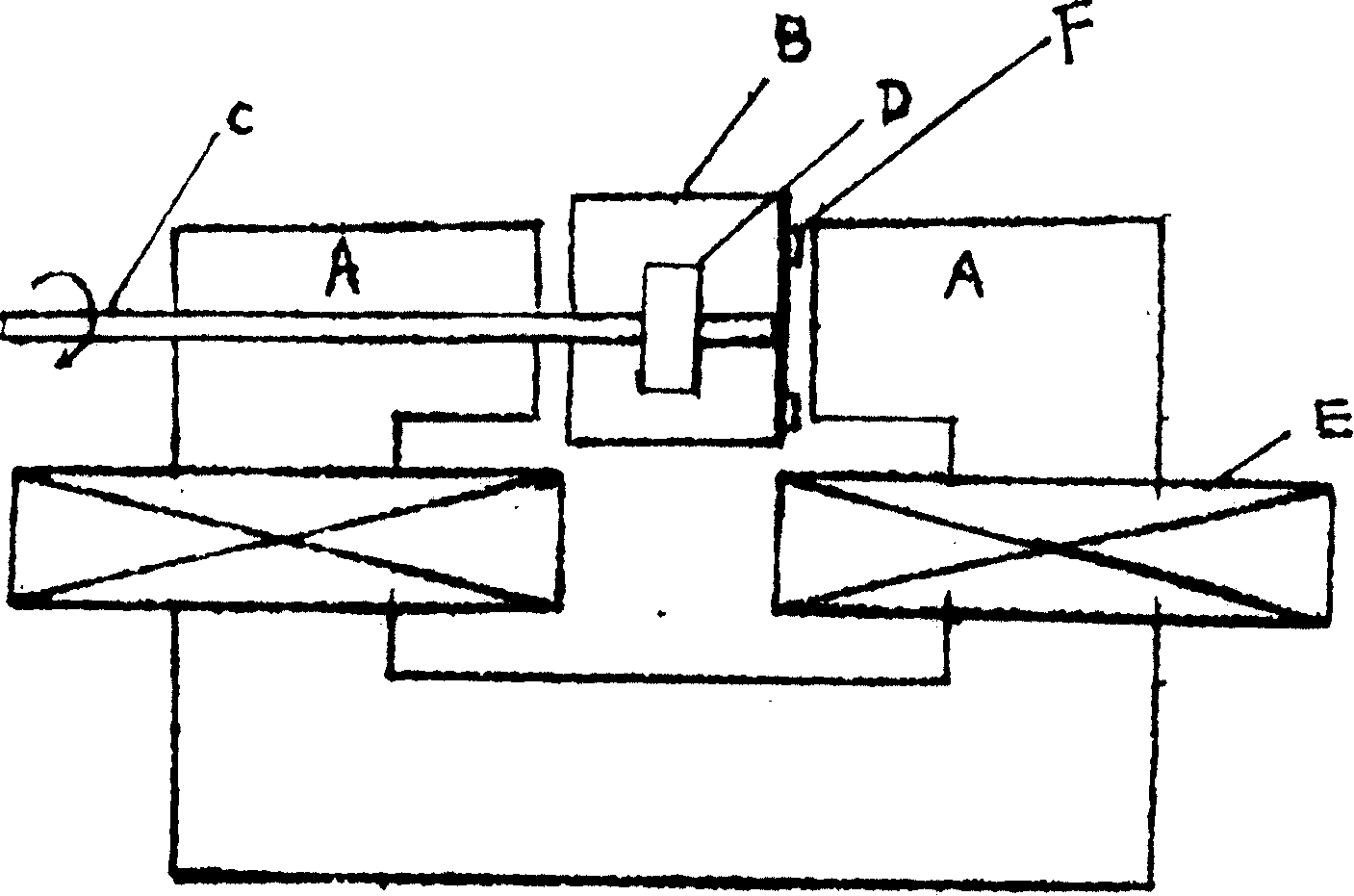

Embodiment 1

[0010] Example 1, a circular device with an outer diameter of Φ80mm made of FeCrCo alloy through high-temperature supersolvation treatment (treatment temperature is 1000-1300°C) is fixed on the front end of the rotating shaft C of the device of the present invention, and is subjected to magnetic field heat treatment. A magnetic field is applied while warming up. The device rotates continuously with the rotation of the axis C in the magnetic field generated by the electromagnet A. The rotation speed is 10-30 rpm, the heat treatment temperature is about 600-700°C, the magnetic field strength is 2000-3000Oe, and the holding time is 1-2 hours. After the treatment, the device was cooled out of the furnace, and tempered at 500-600°C. The magnetic flux of the three products was tested. The inhomogeneity is shown in Table 1:

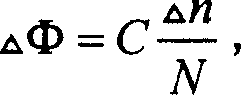

[0011] serial number

ΔΦ after magnetic stabilization

(%)

ΔΦ after high temperature

(%)

ΔΦ after low temperature

(%) ...

Embodiment 2

[0014] Embodiment 2, the device is the ring that the diameter that material AlNiCo or FeCoV alloy is made is Φ 100mm, carries out magnetic field heat treatment with the device of the present invention, and the rotating speed of axis C is 30-60 rev / min, adds magnetic field when heating up, and intensity is 1000- 2000Oe, the heat treatment temperature is 700-850°C, and the holding time is 1-2 hours. The uniformity of the magnetic flux after the device is magnetized is similar to the results in Table 1 (the details are omitted).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com