Split type rotational molding machine

A rotomolding machine, split-type technology, applied in the direction of coating, etc., to achieve the effect of reducing the overall space, reducing the difficulty of installation, and improving the stability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

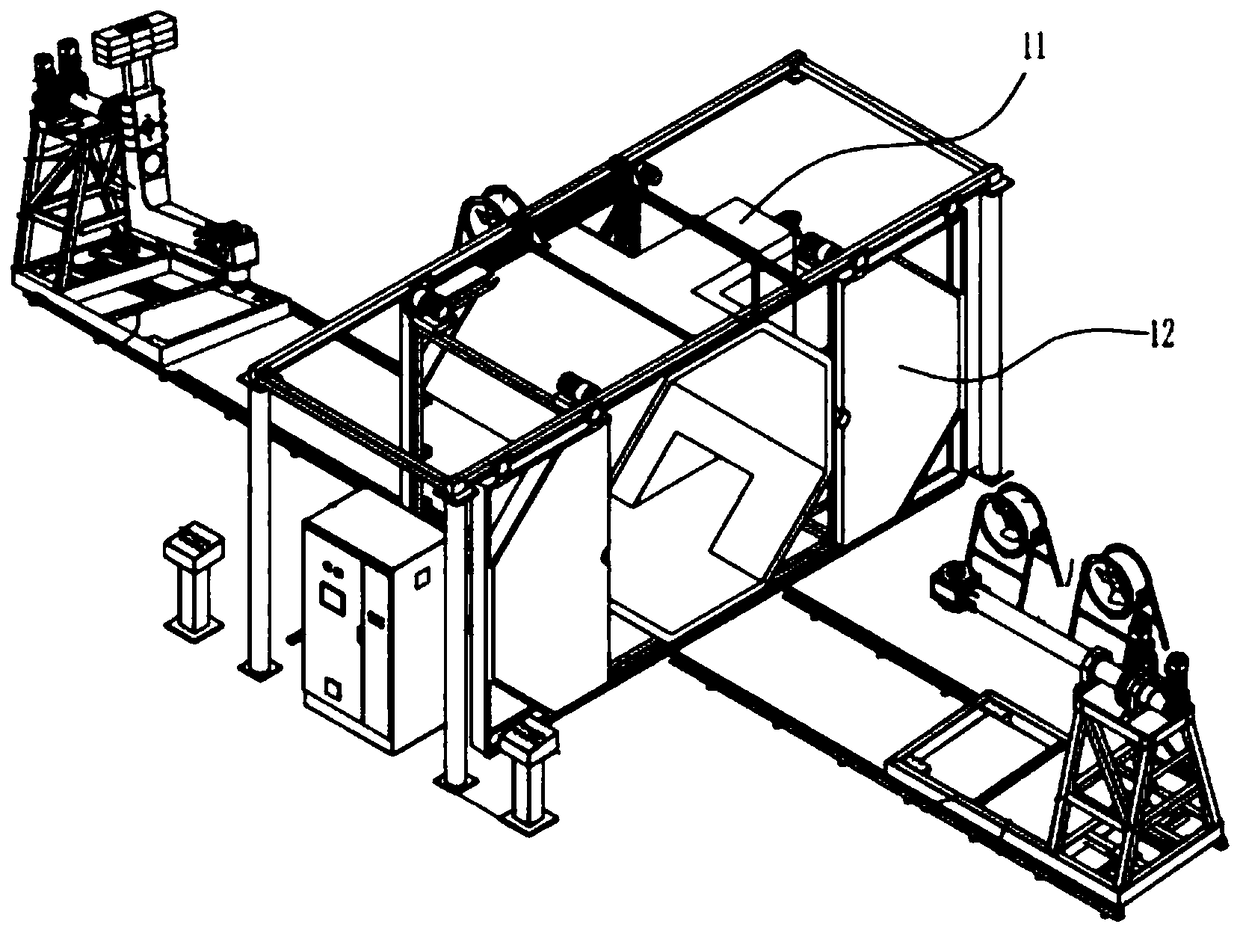

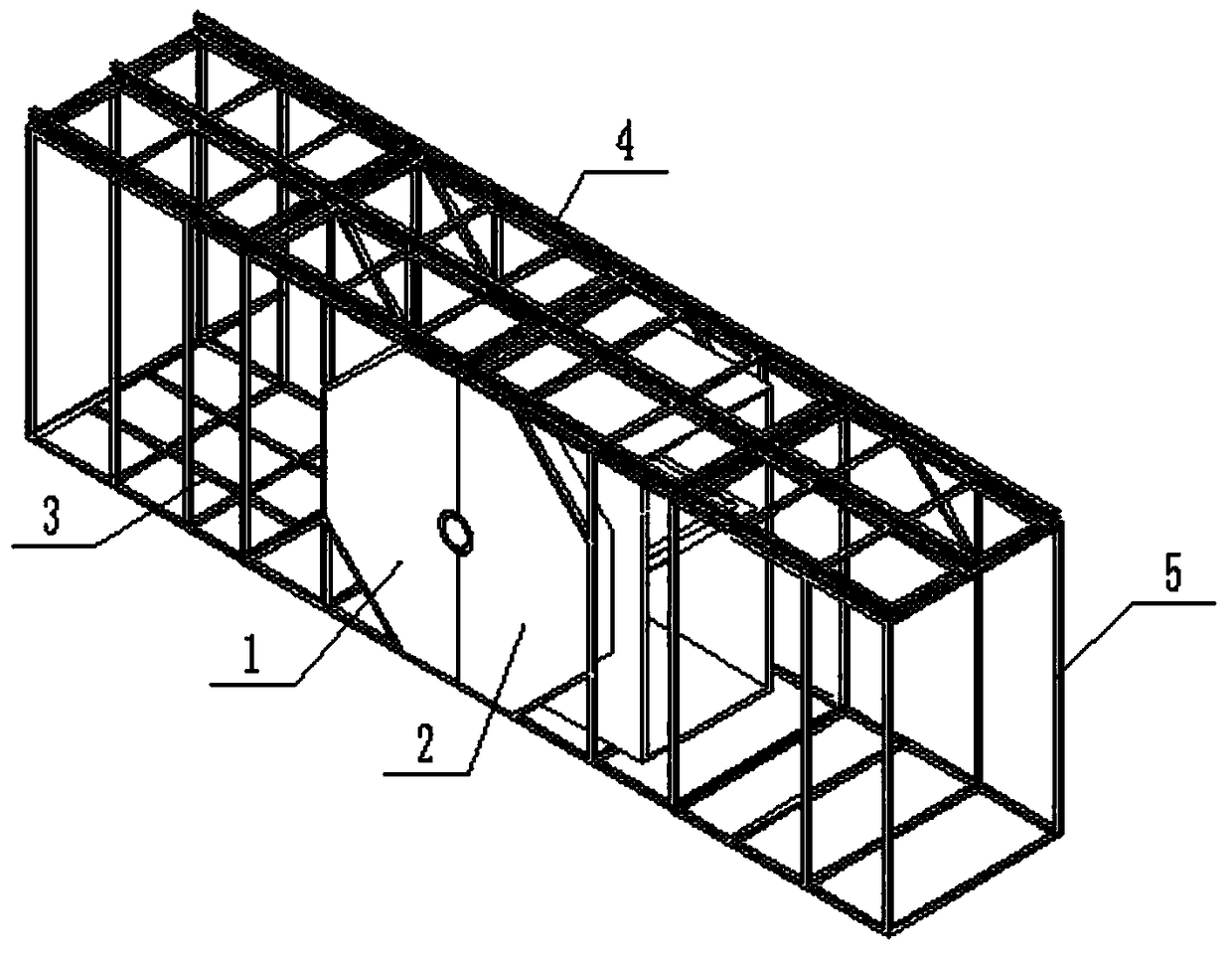

[0022] Such as figure 2 As shown, a split type rotational molding machine comprises a left oven 1, a right oven 2, and a trolley arranged on both sides of the left oven 1 and the right oven 2 and a rotomolding arm on the top of the trolley (the structure is in the figure 2 is shown, please refer to the figure 1 ), the bottom of left oven 1 and / or right oven 2 of the present invention is provided with guide rail 3, and left oven 1 and / or right oven 2 is provided with driving device to drive it to move on guide rail 3, and left oven 1 and right oven 2 are relative When moving and fastening, it forms a sealed cavity with the rotomolding arm. The present invention divides the original oven into two ovens that can be movable and fastened. Since the left oven 1 and the right oven 2 have wider bottoms, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com