Precise adjustable ballast device

A pressure-adjustable and precise technology, used in transportation and packaging, ships, special-purpose ships, etc., can solve the problems of small adjustment range, high system complexity, leakage, etc., to achieve precise control of adjustment rate and quality, and system complexity. Low, wide adjustment range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

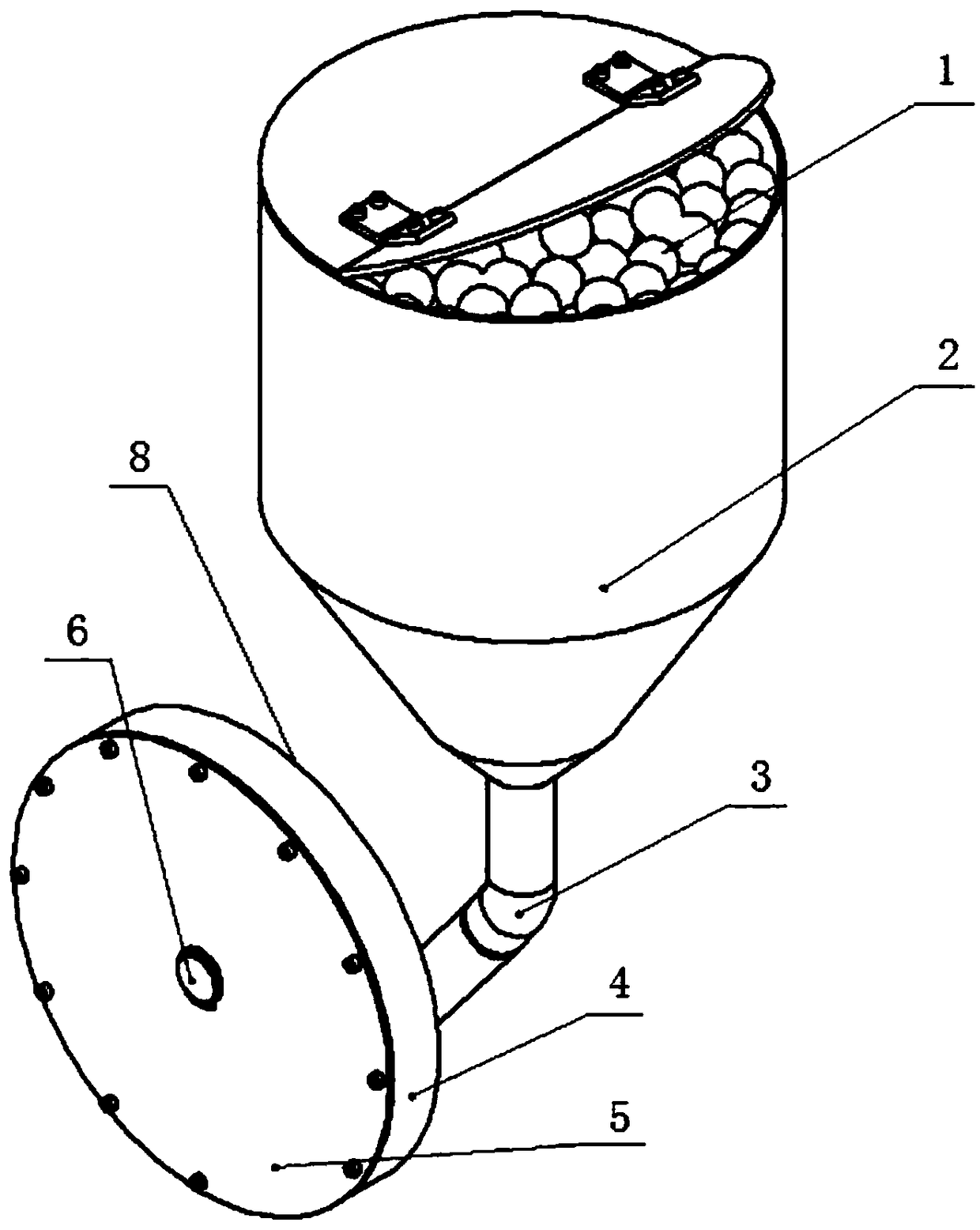

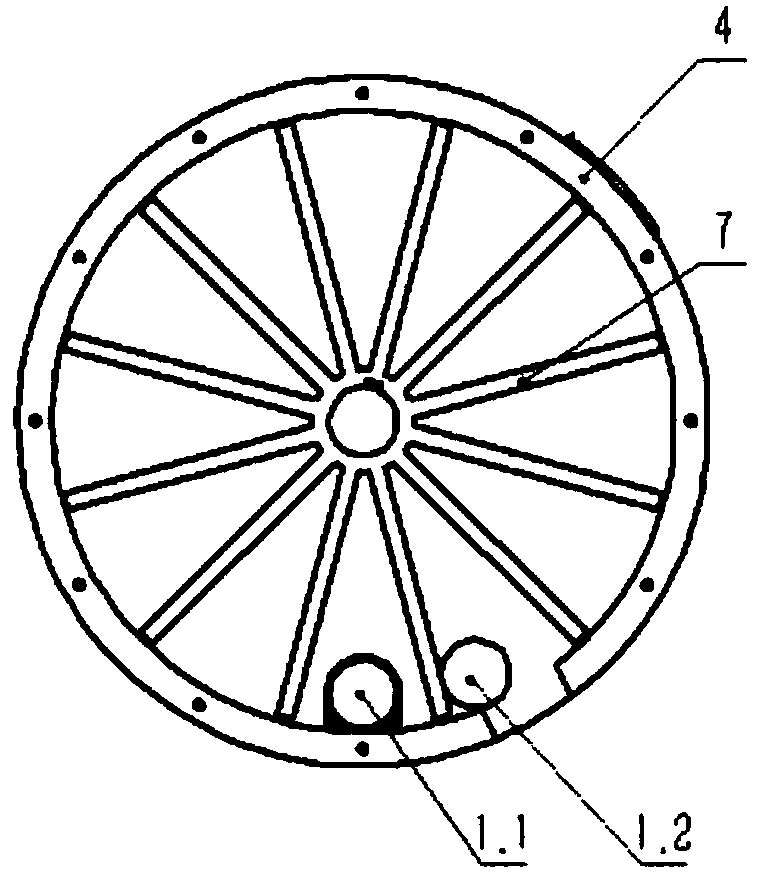

[0035] The working principle of the precision adjustable ballast device provided by the present invention is as follows: the whole piece of ballast is divided into parts, stored in the ballast tank in the form of small balls, and the small balls go straight to the shell along the pipeline. When there is a need to adjust the ballast, the rotating shaft drives the impeller to rotate (whether it is forward or reverse), and only one small ball can be accommodated between every two impeller blades, and it is gradually pushed to the circumferential opening of the shell, under the action of its own gravity come down. The rest of the balls enter the shell one by one and fall down repeatedly. The quality of each small ball is certain, and by adjusting the rotational speed and the number of turns, the quality and rate of load dumping can be precisely controlled, so as to achieve the purpose of precisely adjusting the ballast.

[0036] The action relationship of the whole device is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com