Telescopic boom and mobile crane

A telescopic, boom technology used in cranes, transportation and packaging to solve problems such as unfavorable stress spikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

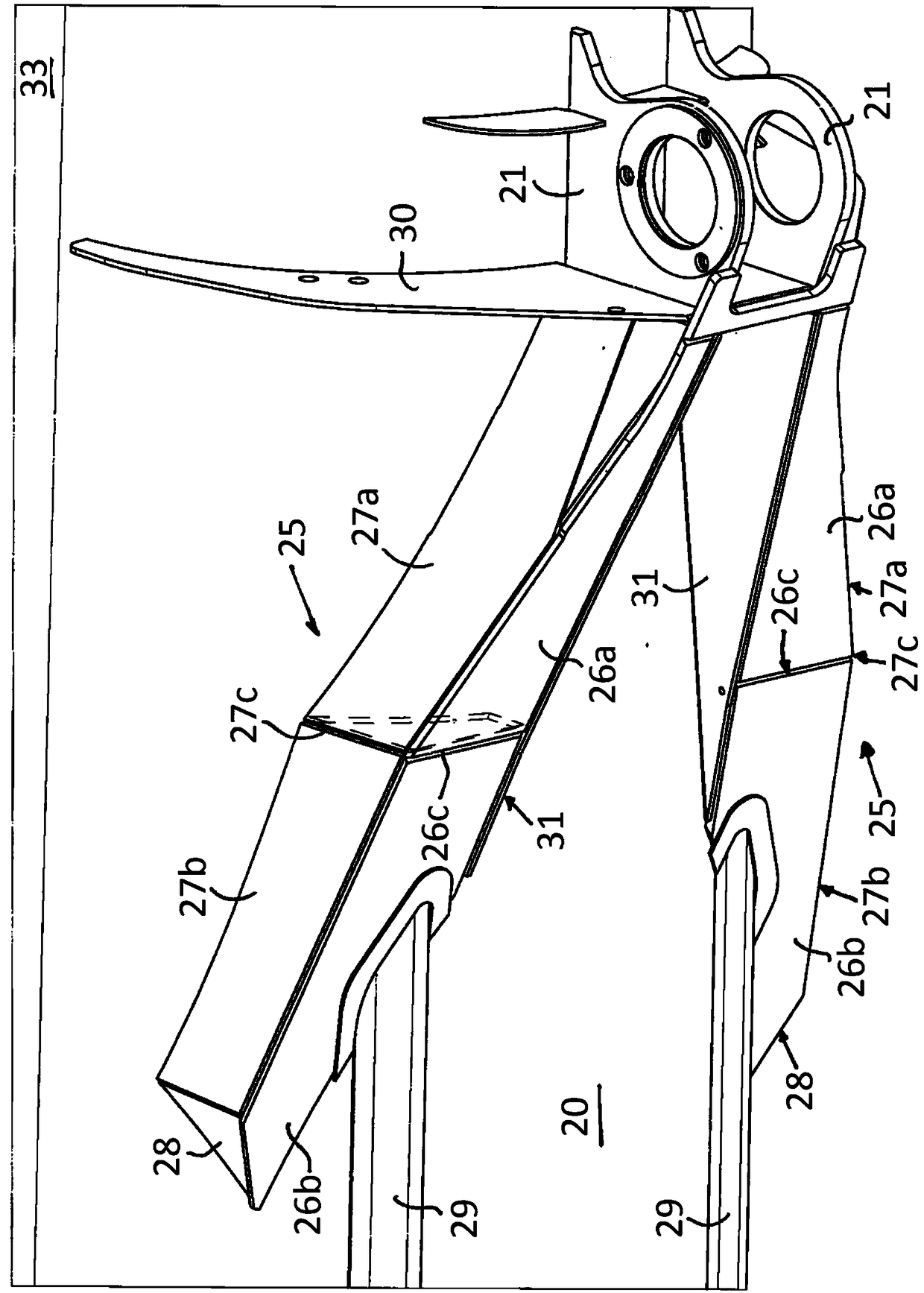

[0029] image 3 and Figure 4 A novel construction of the telescoping boom is now shown. It can be seen that a sub-region of the lower housing 20 of the telescopic boom has a bolt receptacle for coupling a luffing cylinder. To accommodate the bolts of the luffing cylinder, two bolt bearing plates 21 are provided, which have corresponding reinforcing plates. Adjoined to it are two narrow closed board boxes 25 , which are constructed identically to each other. The two boxes 25 each comprise a two-part cover plate with individual elements 26 a , 26 b which are connected to one another via an edge 26 c. The two outer side walls of the box structure 25 are formed in two parts with individual elements 27a, 27b which are in contact with one another via an edge 27c. A closing plate 28 is arranged at the end-side end. The inner side walls 31 of the crate structure are formed in one piece.

[0030] Inside each of the two box-shaped structures 25 there is an inner upright plate 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com