Inner wall paint with temperature regulating and energy storage functions and preparation method thereof

An interior wall coating and energy storage technology, applied in coatings and other directions, can solve problems such as poor thermal conductivity, easy blockage of filler pores, poor energy storage effect, etc., and achieve the effects of shortening response time, promoting heat exchange, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

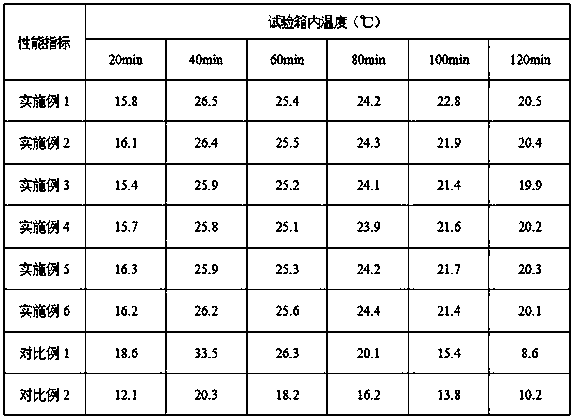

Examples

Embodiment 1

[0030] (1) Heating the paraffin to melt, immersing the diatomite in the paraffin, making the paraffin adsorb in the pores of the diatomite under the action of ultrasound, cooling down to obtain the diatomite particles adsorbing the paraffin;

[0031] (2) Add the nano-thermal conductive filler into the polytetrafluoroethylene emulsion, disperse it evenly by ultrasonic, and then spray it on the surface of the paraffin-absorbing diatomite particles prepared in step (1), and dry them after skinning to form a coating on the surface of the particles. cladding, to prepare temperature-regulating energy-storage fillers; the nano-thermally-conductive fillers are nano-alumina; the solid content of the polytetrafluoroethylene emulsion is 36%; in the temperature-regulating energy-storage fillers, 3 parts by weight of nano-thermally conductive fillers, 9 parts by weight of polytetrafluoroethylene Parts by weight, 26 parts by weight of paraffin, 62 parts by weight of diatomaceous earth;

[0...

Embodiment 2

[0037] (1) Heating the paraffin to melt, immersing the diatomite in the paraffin, making the paraffin adsorb in the pores of the diatomite under the action of ultrasound, cooling down to obtain the diatomite particles adsorbing the paraffin;

[0038] (2) Add the nano-thermal conductive filler into the polytetrafluoroethylene emulsion, disperse it evenly by ultrasonic, and then spray it on the surface of the paraffin-absorbing diatomite particles prepared in step (1), and dry them after skinning to form a coating on the surface of the particles. cladding layer to prepare temperature-regulating energy-storage filler; the nano-thermal conductive filler is nano-aluminum nitride; the solid content of polytetrafluoroethylene emulsion is 30%; in the temperature-regulated energy-storage filler, 2 parts by weight of nano-thermal conductive filler, polytetrafluoroethylene 8 parts by weight, 20 parts by weight of paraffin, 70 parts by weight of diatomaceous earth;

[0039] (3) Mix the te...

Embodiment 3

[0042](1) Heating the paraffin to melt, immersing the diatomite in the paraffin, making the paraffin adsorb in the pores of the diatomite under the action of ultrasound, cooling down to obtain the diatomite particles adsorbing the paraffin;

[0043] (2) Add the nano-thermal conductive filler into the polytetrafluoroethylene emulsion, disperse it evenly by ultrasonic, and then spray it on the surface of the paraffin-absorbing diatomite particles prepared in step (1), and dry them after skinning to form a coating on the surface of the particles. cladding layer to obtain temperature-regulating energy-storage filler; the nano-thermally-conductive filler is nano-boron nitride; the solid content of the polytetrafluoroethylene emulsion is 40%; in the temperature-regulating energy-storage filler, 4 parts by weight of nano-thermally conductive filler, polytetrafluoroethylene 12 parts by weight, 30 parts by weight of paraffin, 54 parts by weight of diatomaceous earth;

[0044] (3) Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com