Dry quenching furnace with inclined pre-storage gas flow passages and annular pre-storage chamber and working method

A technology of airflow channels and pre-storage chambers, which is applied in coke ovens, petroleum industry, coke cooling, etc., can solve problems such as the limitation of the length and height of corbels, increase the flow rate of circulating gas, and increase the energy consumption of the circulation system, so as to avoid airflow Unsmooth, to avoid the effect of increasing the system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

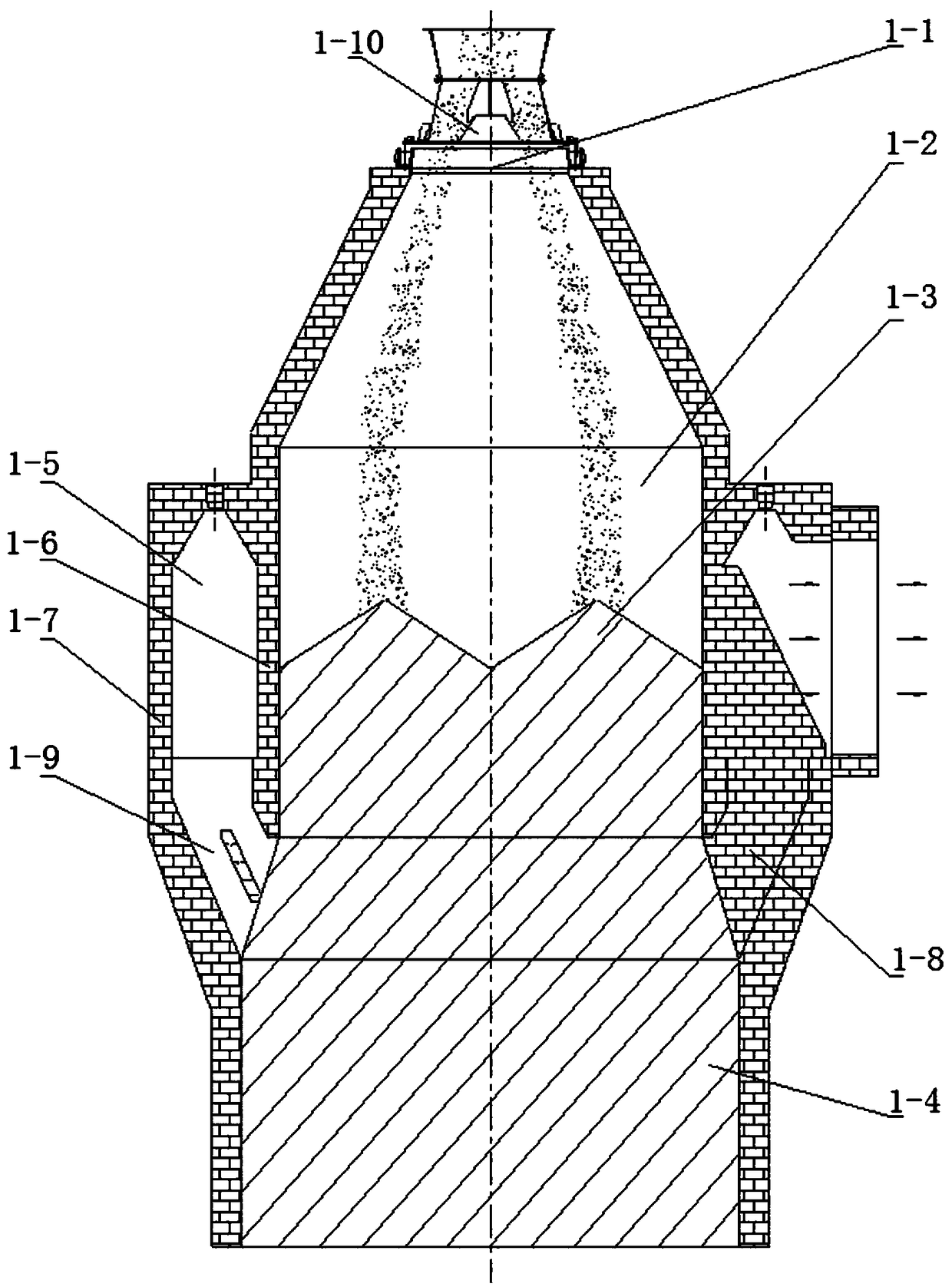

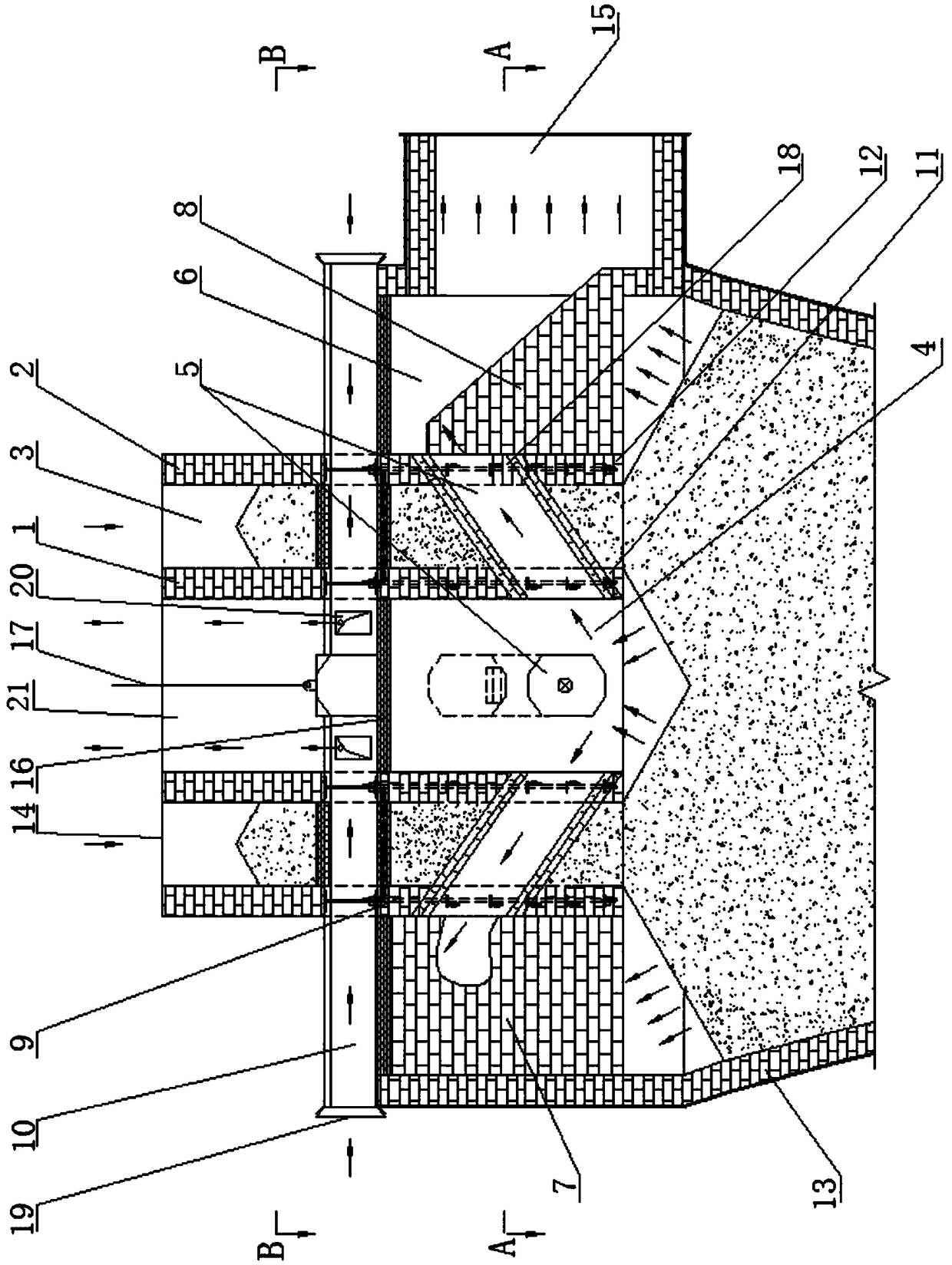

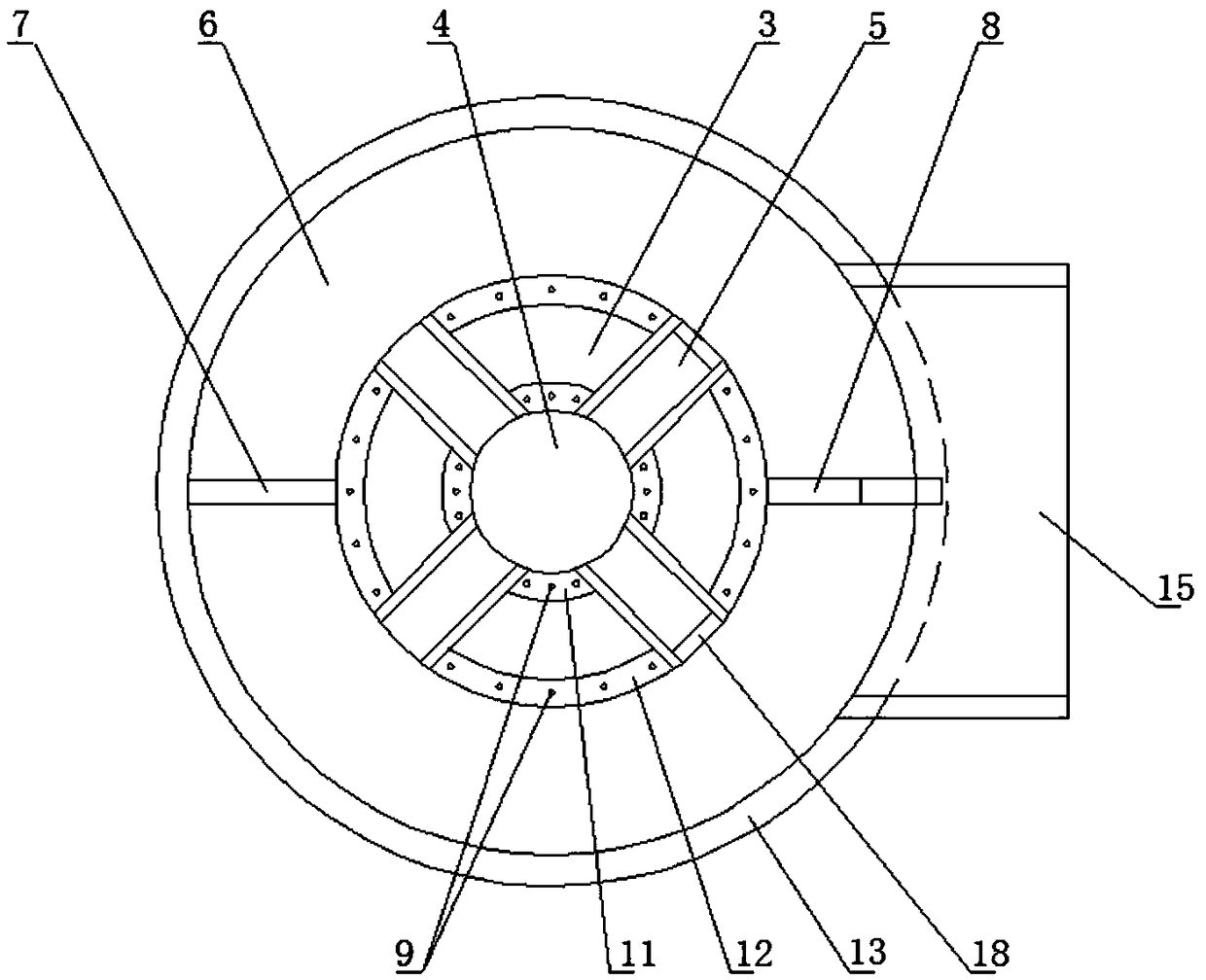

[0035] Such as Figure 2-Figure 4 As shown, the CDQ furnace with an inclined pre-storage air flow channel and an annular pre-storage chamber according to the present invention includes a pre-storage chamber and a cooling chamber connected up and down; An annular pre-storage chamber 3 composed of an inner ring wall 11 and a lower outer ring wall 12; a roof 16 is provided on the top of the cooling outer wall 13, and an upper hanger 10 is arranged above the roof 16; the upper inner ring wall 1 and the upper outer ring wall 2 are built together Built on the upper hanger 10; the lower inner ring wall 11 and the lower outer ring wall 12 are set under the upper hanger 10, and the ring passage formed by the lower inner ring wall 11 and the lower outer ring wall 12 is connected with the upper inner ring wall 1 and the upper ring wall. The annular channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com