concrete vibrating device

A vibrating device and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to reduce noise, high noise, and environmental impact with flat vibrators, so as to reduce the external transmission of vibration and reduce the impact on the environment. Noise, the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below in conjunction with embodiment.

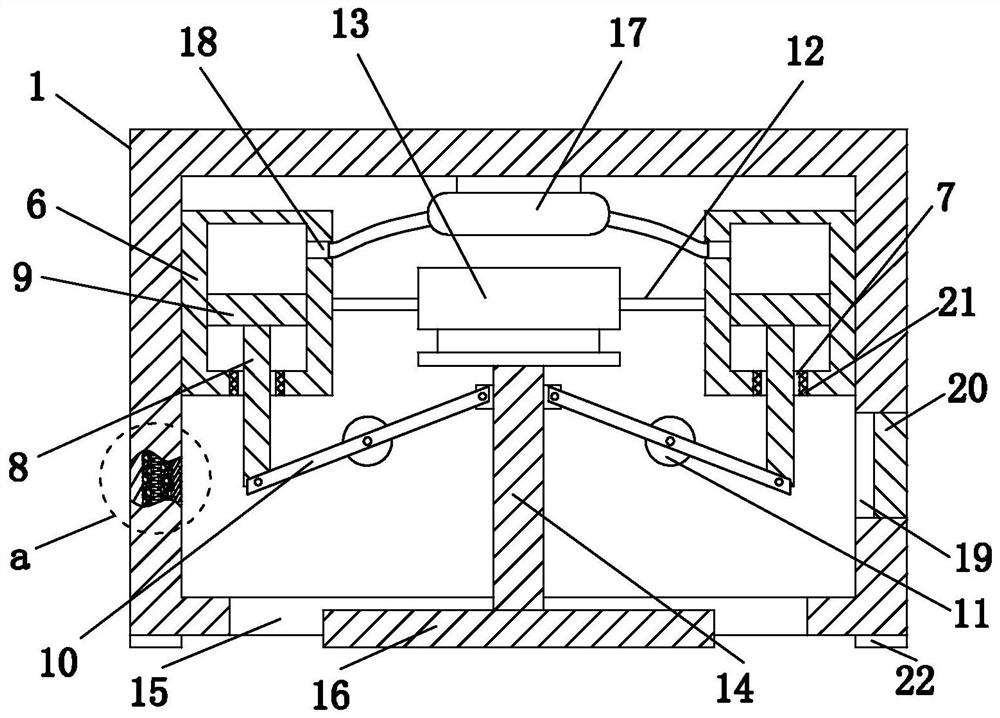

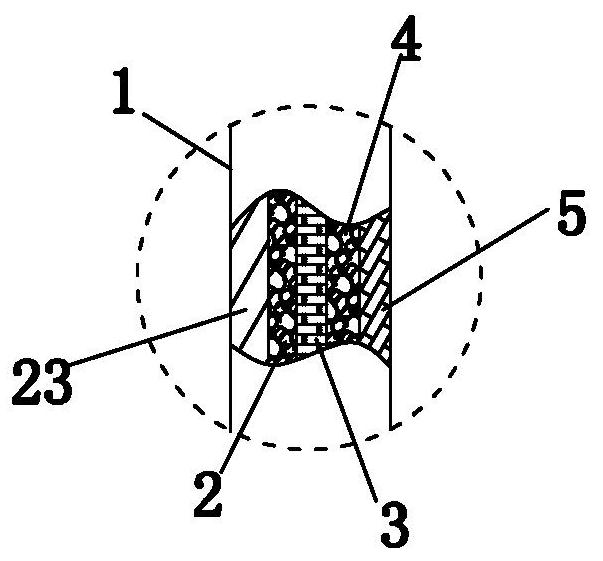

[0017] like figure 1 , figure 2 A concrete vibrating device is shown, which includes a sound-insulating shell 1. The sound-insulating shell 1 is in the shape of a square shell. The sound-insulating shell 1 sequentially includes an outer layer 23, a first sound-insulating felt layer 2, and a light steel keel layer from outside to inside. 3. The second sound-insulating felt layer 4, gypsum board 5, and light steel keel layer 3 have the characteristics of light weight and high strength, which can ensure the strength of the sound-insulating shell 1, but the weight is not too heavy. The four sides and the upper end of the soundproof shell 1 are all closed, and the lower end is provided with a vibrating port 15 .

[0018] There are two left and right cylinders 6 inside the soundproof shell 1, and the two cylinders 6 are respectively fixed on the innermost gypsum board 5 of the soundproof she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com