Dust recovery device for screw polishers

A dust recovery and polishing machine technology, applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problem of unsatisfactory dust recovery effect, inconvenient collection and processing of sparks, and broken polishing screws. The problem of high chip temperature can improve the utilization rate of resources, reduce noise and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

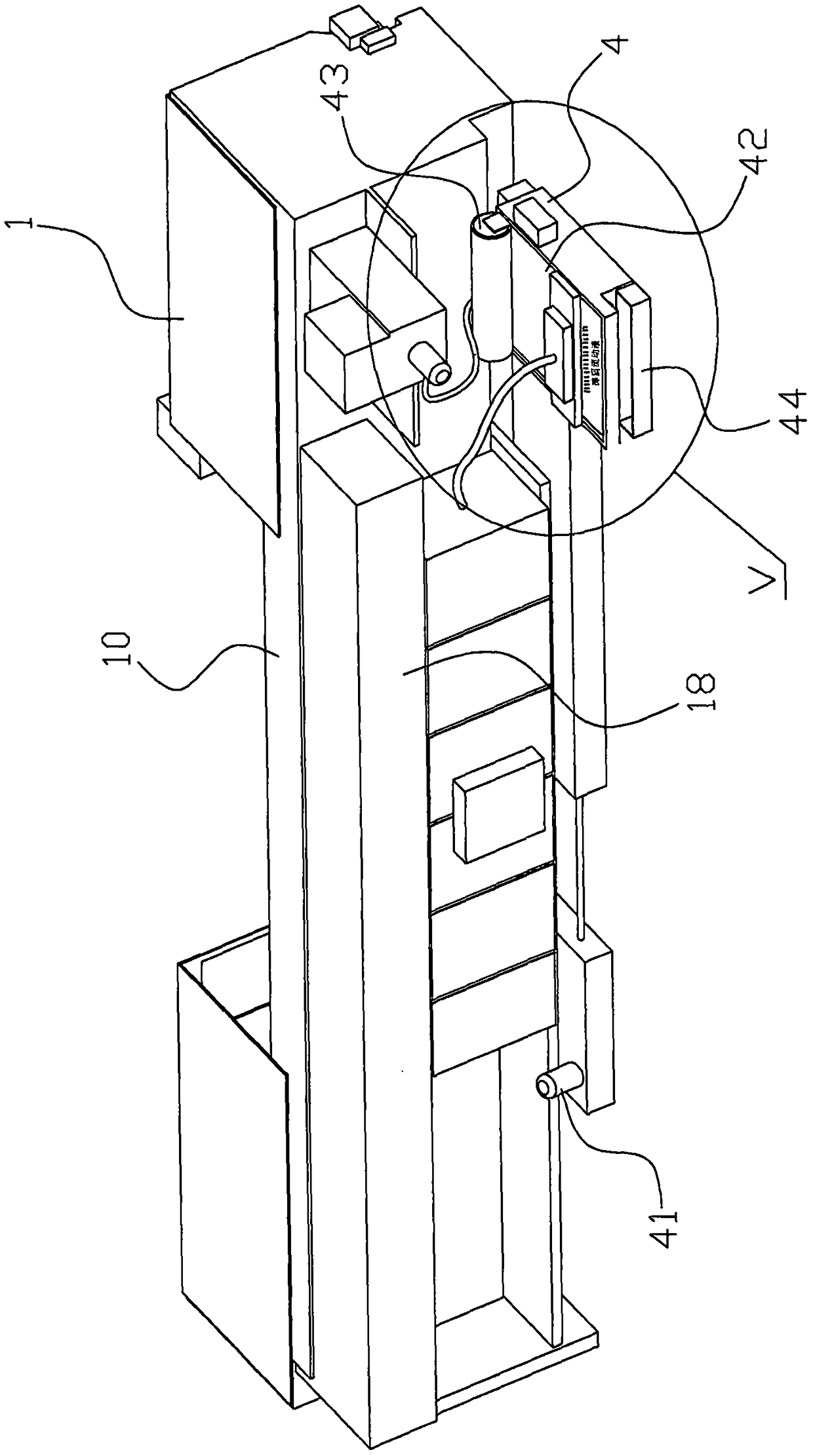

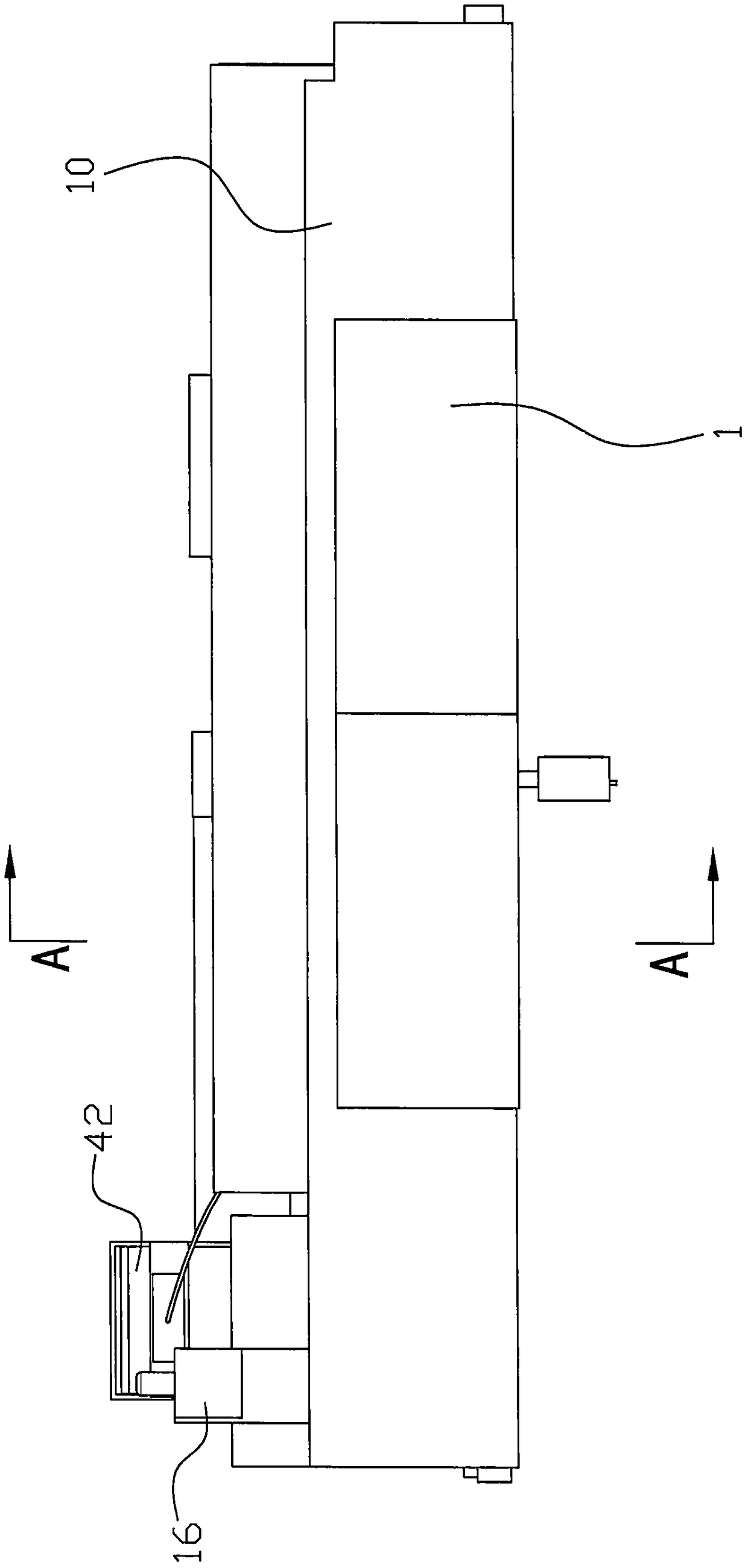

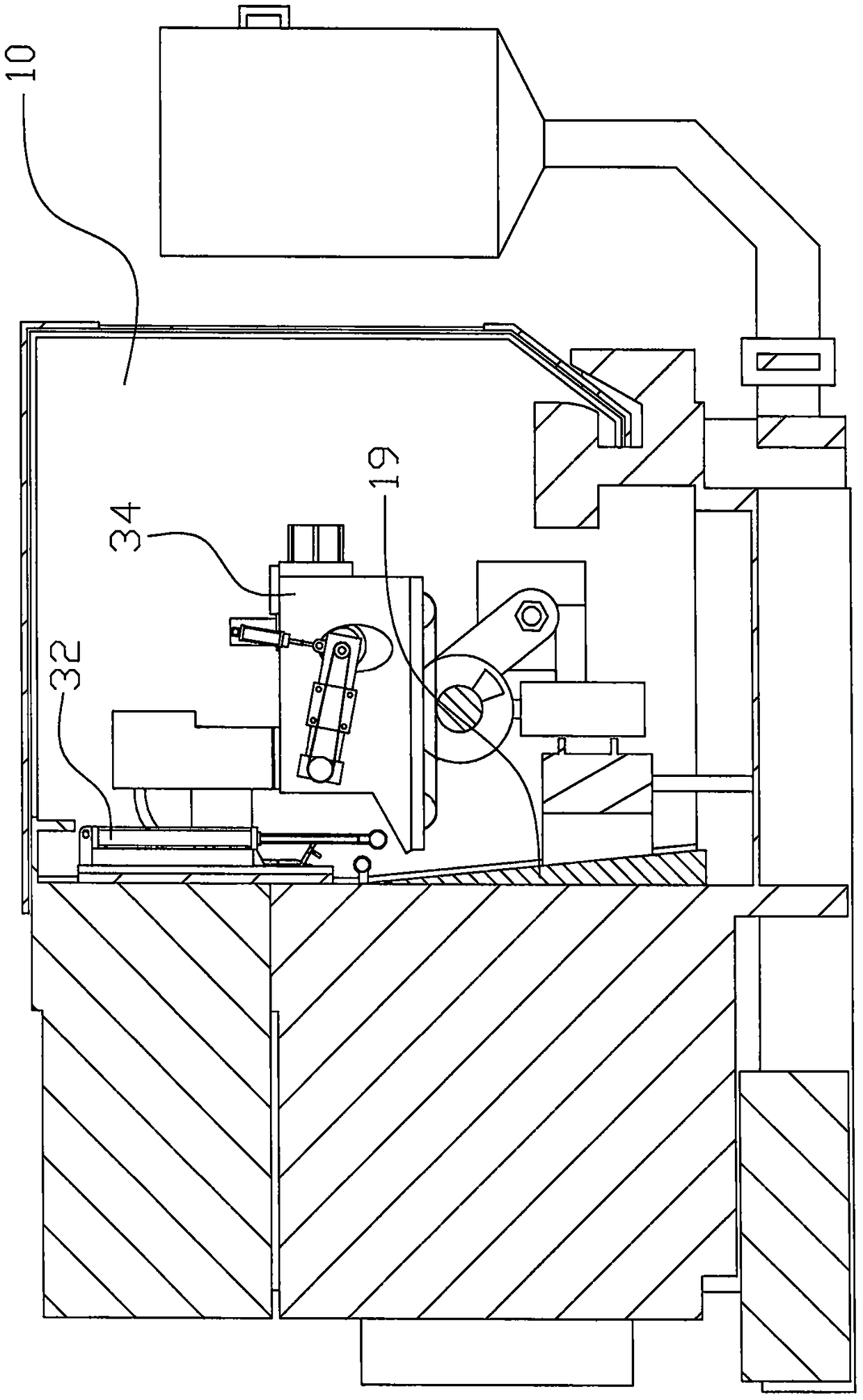

[0036] Such as Figure 1 to Figure 20 As shown, the dust recovery device used on the screw polishing machine of this embodiment includes a polishing debris absorption mechanism, and the polishing debris absorption mechanism includes a debris flow liquid capable of injecting debris into it, and a debris filter part 4 , the debris flow liquid flows to the debris filter part 4, the debris flow liquid container 45 in the debris filter part 4 can move left and right synchronously with the polishing part, and the bottom of the polishing part can move left and right Placed on the slide rail of the machine body 10, the polishing part wears down the screw 11 when polishing, and the ejection direction of the debris with sparks is opposite to the wall 19. The debris flow liquid is transported to the upper pipe or through hole 40 on the wall 19, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com