Diesel generator noise reduction outer shell

A technology for diesel generators and casings, which is applied to layered products, ceramic layered products, synthetic resin layered products, etc., can solve problems such as high noise, and achieve the effects of reducing noise pollution, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

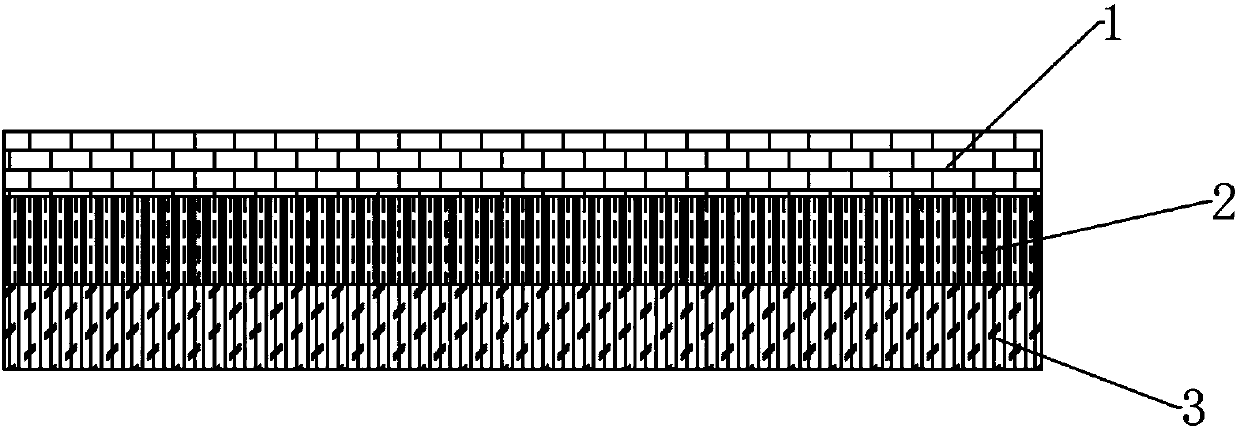

[0014] A noise reduction housing for a diesel generator, characterized in that the housing includes a ceramic layer 1, an acrylic layer 2, and a plastic layer 3, wherein the ceramic layer 1 is attached to one side of the acrylic layer 2, and the plastic layer 3 is attached to the acrylic layer 2 On the other side, the ceramic layer 1, the acrylic fiber layer 2, and the plastic layer 3 are pasted into one.

[0015] On the basis of the above technical solutions, the following conditions are met:

[0016] The thickness of the ceramic layer 1 is equal to the sum of the thicknesses of the acrylic fiber layer 2 and the plastic layer 3 .

[0017] The lamination is realized by means of gluing.

Embodiment 2

[0019] A noise reduction housing for a diesel generator, characterized in that the housing includes a ceramic layer 1, an acrylic layer 2, and a plastic layer 3, wherein the ceramic layer 1 is attached to one side of the acrylic layer 2, and the plastic layer 3 is attached to the acrylic layer 2 On the other side, the ceramic layer 1, the acrylic fiber layer 2, and the plastic layer 3 are pasted into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com