Liquid supply method suitable for fracturing construction in mountain area

A fracturing fluid and fluid supply technology, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of inability to meet continuous long-term fracturing, long fracturing operation time, and long preparation time, etc. Achieve the effect of realizing safe, energy-saving and environmental protection operations, shortening the installation cycle, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

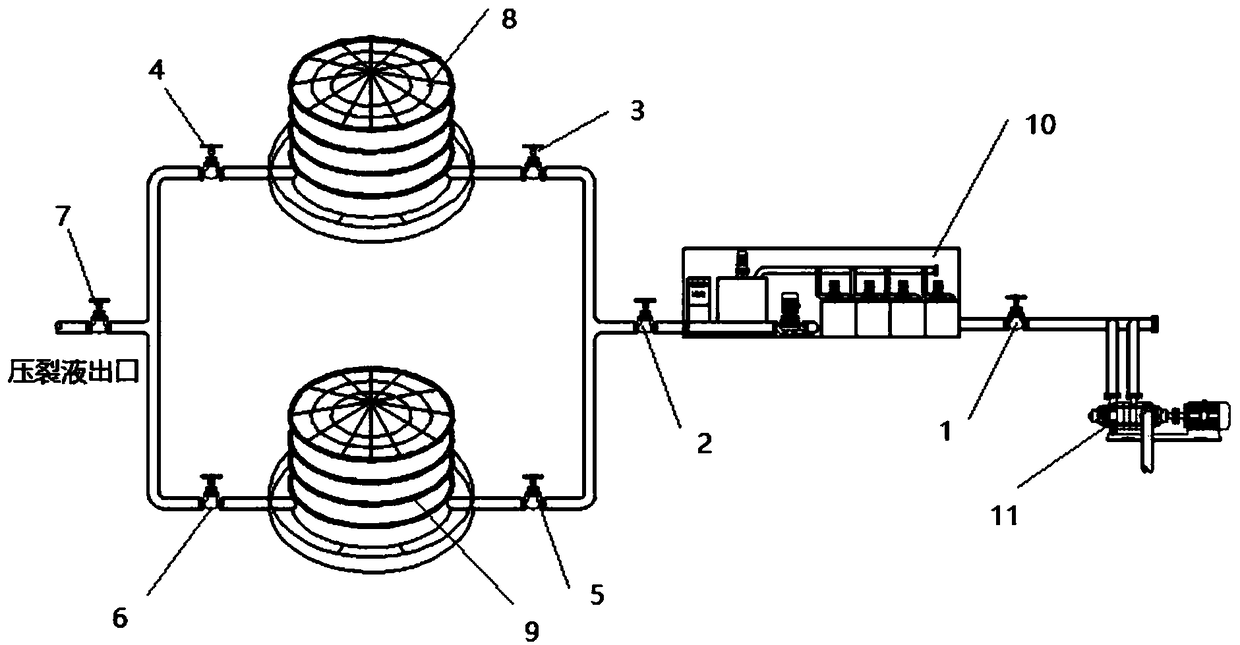

[0057] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0058] A liquid supply method suitable for fracturing construction in mountainous areas. Two sets of fracturing fluid tanks are used as 1# tank 8 and 2# tank 9 respectively, and 3# valves 3 and 4# valves are respectively installed before and after 1# tank 8 4. Set 5# valve 5 and 6# valve 6 before and after 2# tank 9, merge the pipelines before 5# valve 5 and 3# valve 3, and set 2# valve 2 and 1 on the merged pipeline #valve 1, and a mixing device 10 is provided between 2# valve 2 and 1# valve 1, a clean water pump 11 is provided in front of 1# valve 1, and the pipeline is merged after 4# valve 4 and 6# valve 6, And the combined pipeline is equipped with 7# valve 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com