Automatic dosing system for pulverized coal on molded coal production line

An automatic liquid dispensing and production line technology, applied in the field of pulverized coal automatic liquid dispensing system, can solve the problems of high labor intensity of workers, large labor volume of liquid dispensing production line, influence of liquid dispensing ratio, etc., to achieve uniformity and stability, improve The level of automation and the effect of improving the quality of liquid dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

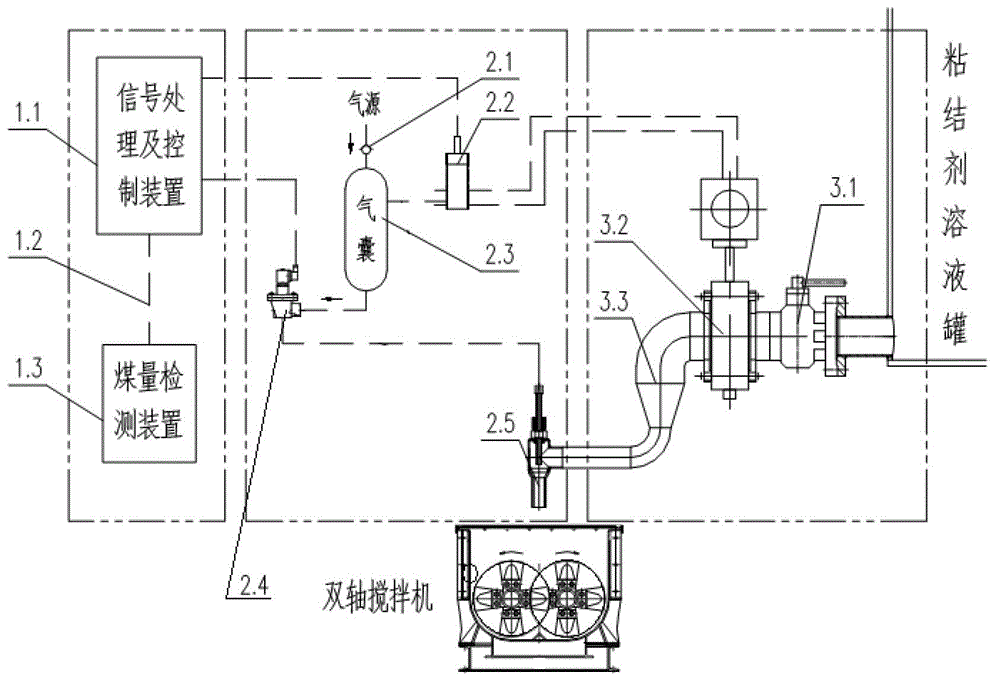

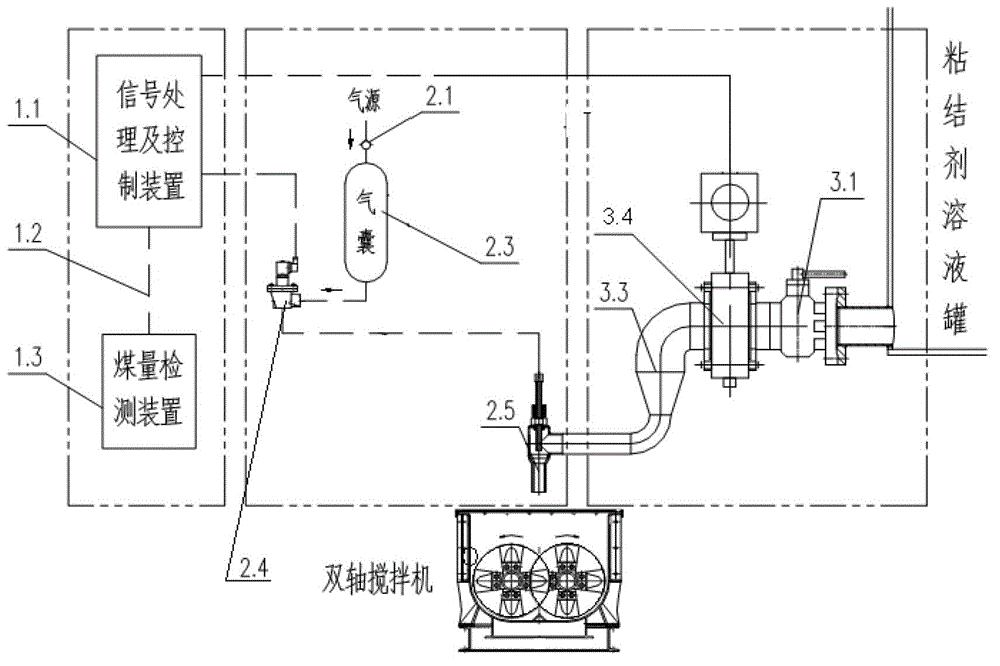

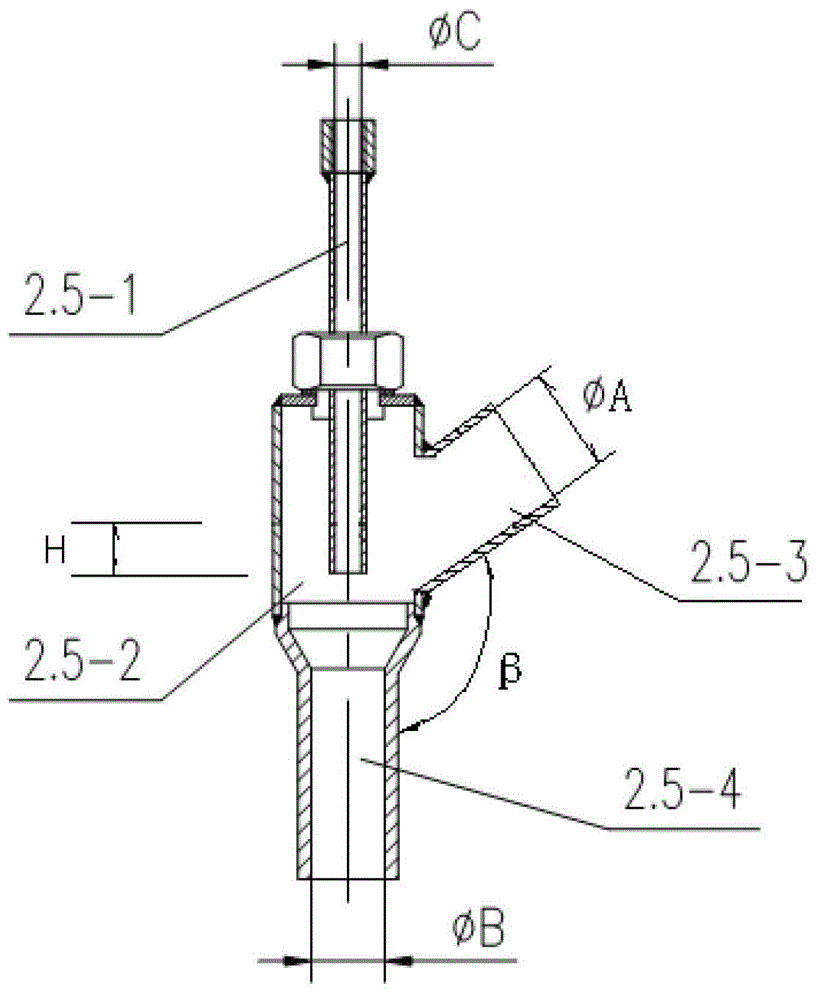

[0029] figure 1 It is a schematic diagram of the system structure principle of the present invention: the pulverized coal automatic liquid distribution system on a coal briquette production line of the present invention includes a control part 1 and an execution part 2, and its control part 1 includes a coal quantity detection device 1.2, and a coal quantity detection device 1.2 The connected signal processing and control device 1.1; the execution part 2 includes the spray gun 2.5, which has a liquid inlet connected to the binder solution tank, and the spray pipe of the spray gun 2.5 is connected to the air source through the electromagnetic pulse valve 2.4, and the electromagnetic pulse valve The control terminal of 2.4 is connected with the pulse output terminal of the signal processing and control device 1.1.

[0030] The liquid inlet of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com