Multi-medium large-displacement hydraulic type injection device

A technology of injection device and large displacement, which is applied in the directions of transportation and packaging, dissolving and mining fluids, etc. It can solve the problems of affecting the effect and success rate of profile control, large measurement errors of medicines, and inadequate management, so as to achieve a fast liquid dispensing process. Continuous, highly automated, fluid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

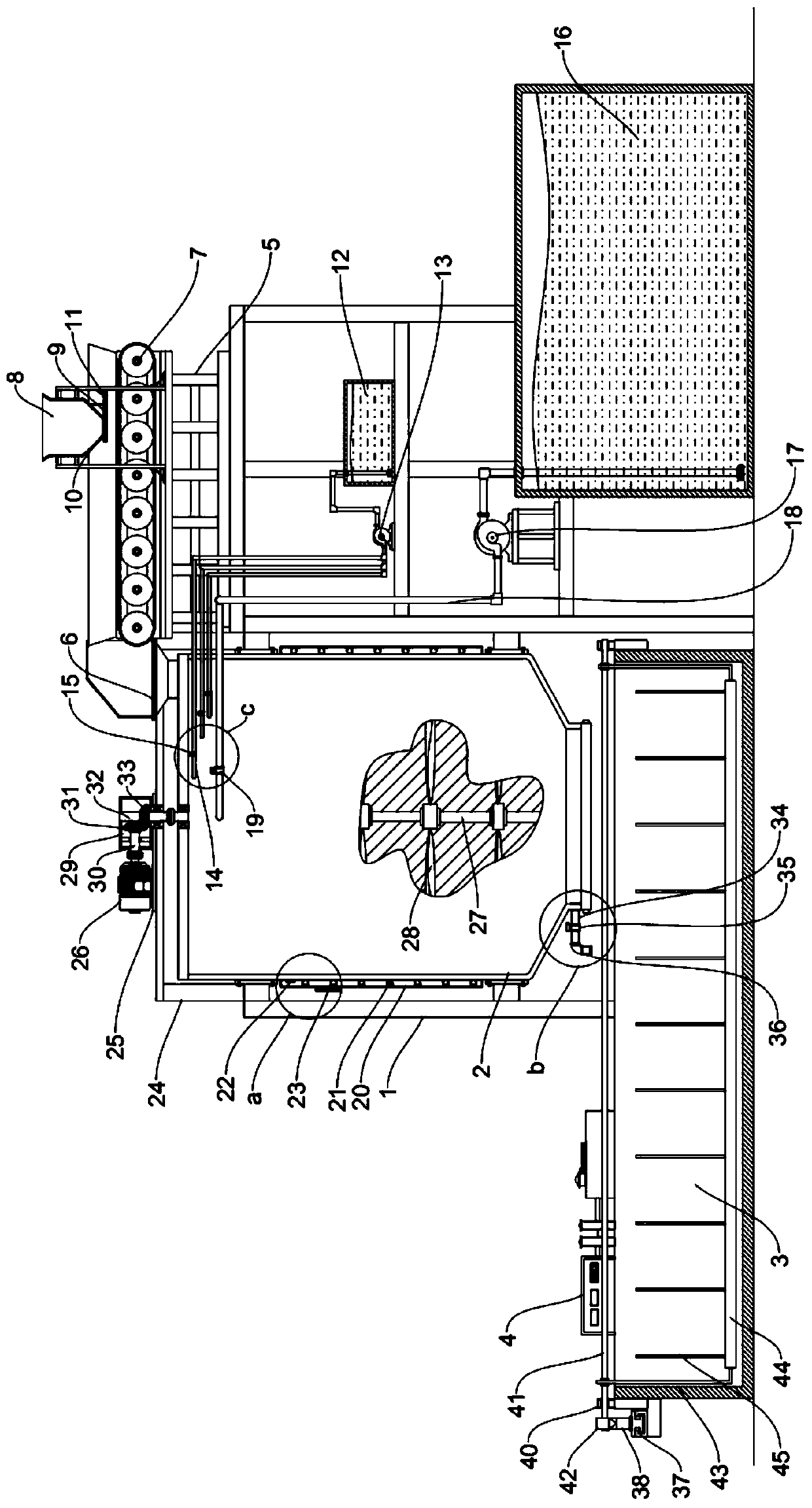

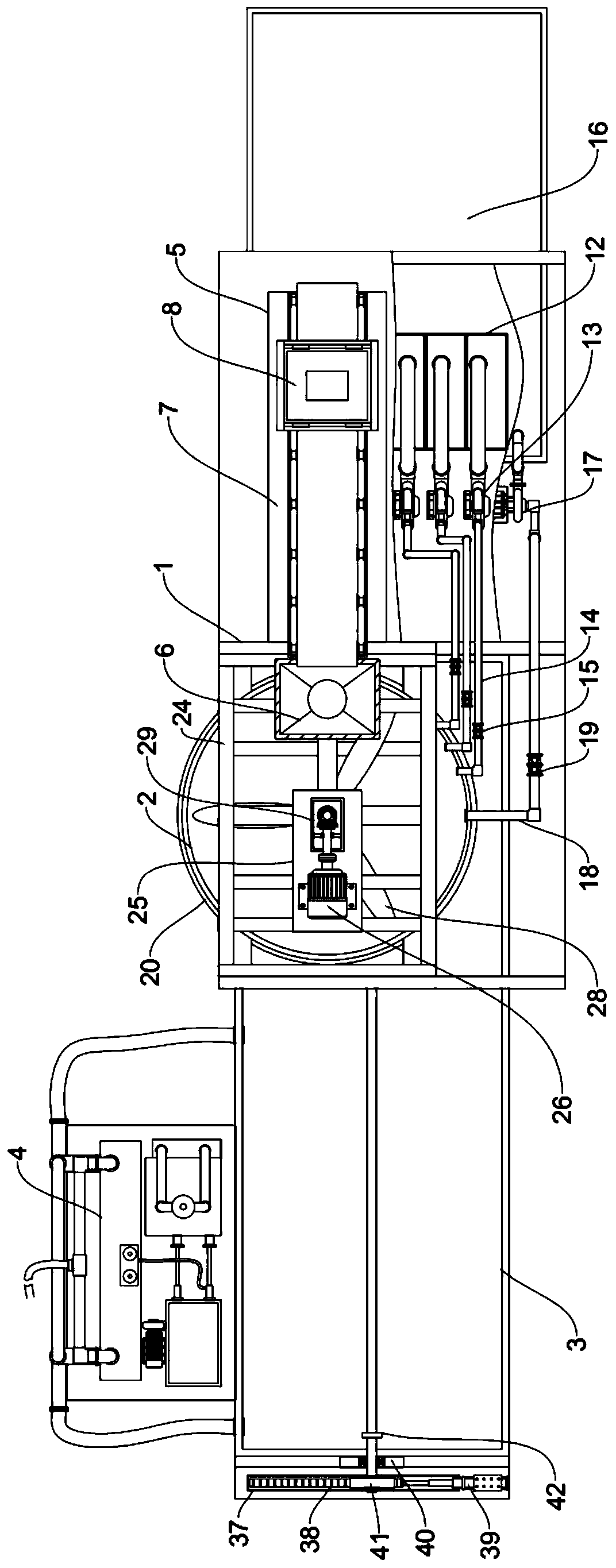

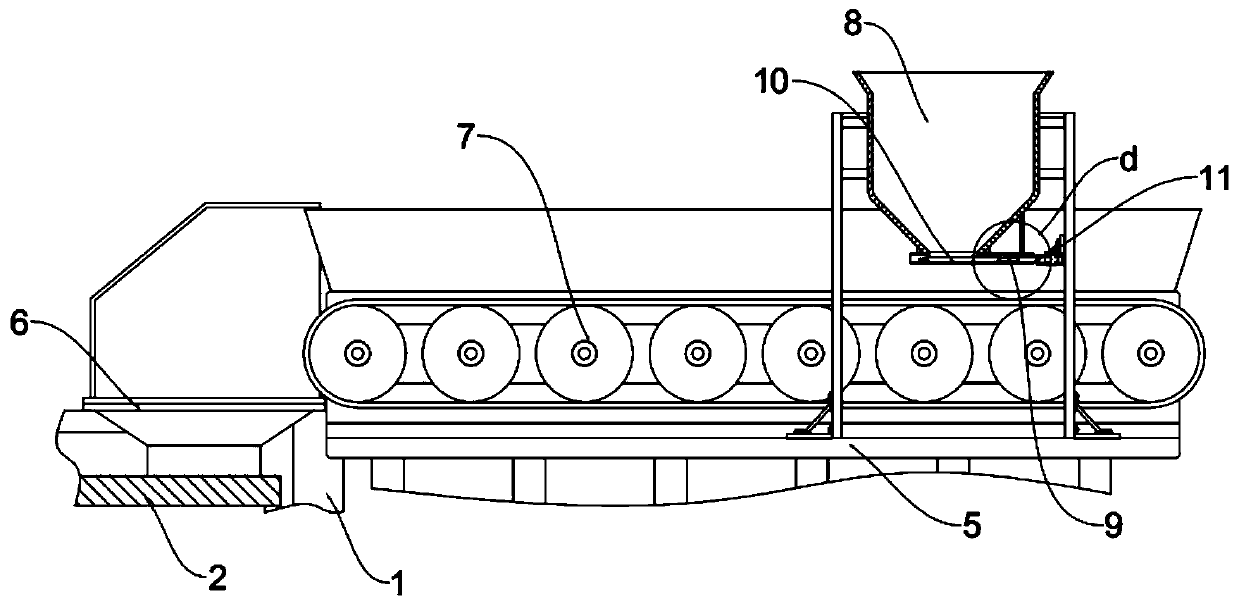

[0044] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-11 As shown, a multi-media large-displacement hydraulic injection device includes a support frame 1, a liquid distribution tank 2, a temporary liquid storage bin 3, and a hydraulic profile control and water plugging pump 4. The liquid distribution tank 2 is installed on the support frame 1 Above, the temporary liquid storage bin 3 is installed under the support frame 1 and is located on the side of the liquid distribution tank 2, and the hydraulic profile control and water plugging pump 4 is installed on the side of the support frame 1, so A profile control fluid export assembly is provided between the liquid distribution tank 2 and the temporary liquid storage bin 3, a multi-media batching mechanism is provided on one side of the liquid distribution tank 2, and a rotary control device is provided on the liquid distribution tank 2. A warm stirring mechanism, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com