Vacuum sucking and feeding system with back flushing function

A vacuum suction and backwashing technology, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., can solve the problems of loading and unloading, unpacking, preparation fastness, difficulty in using powdered activated carbon technology, and accurate quantification Dosing is difficult to control and other problems, to achieve the effect of improving the quality of dosing, convenient implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

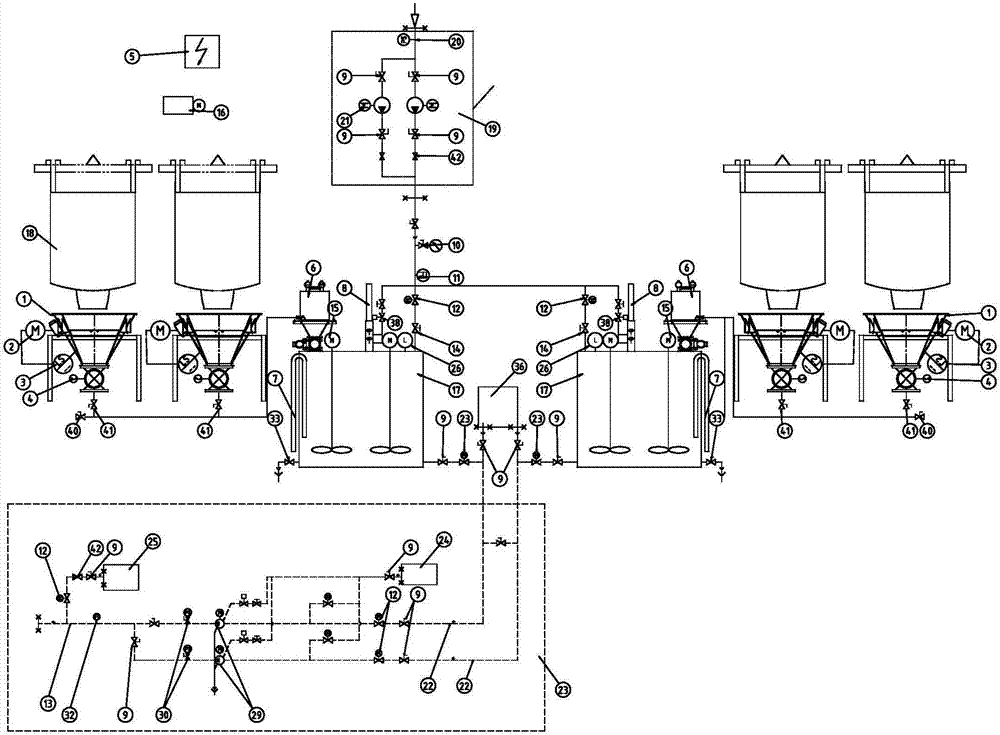

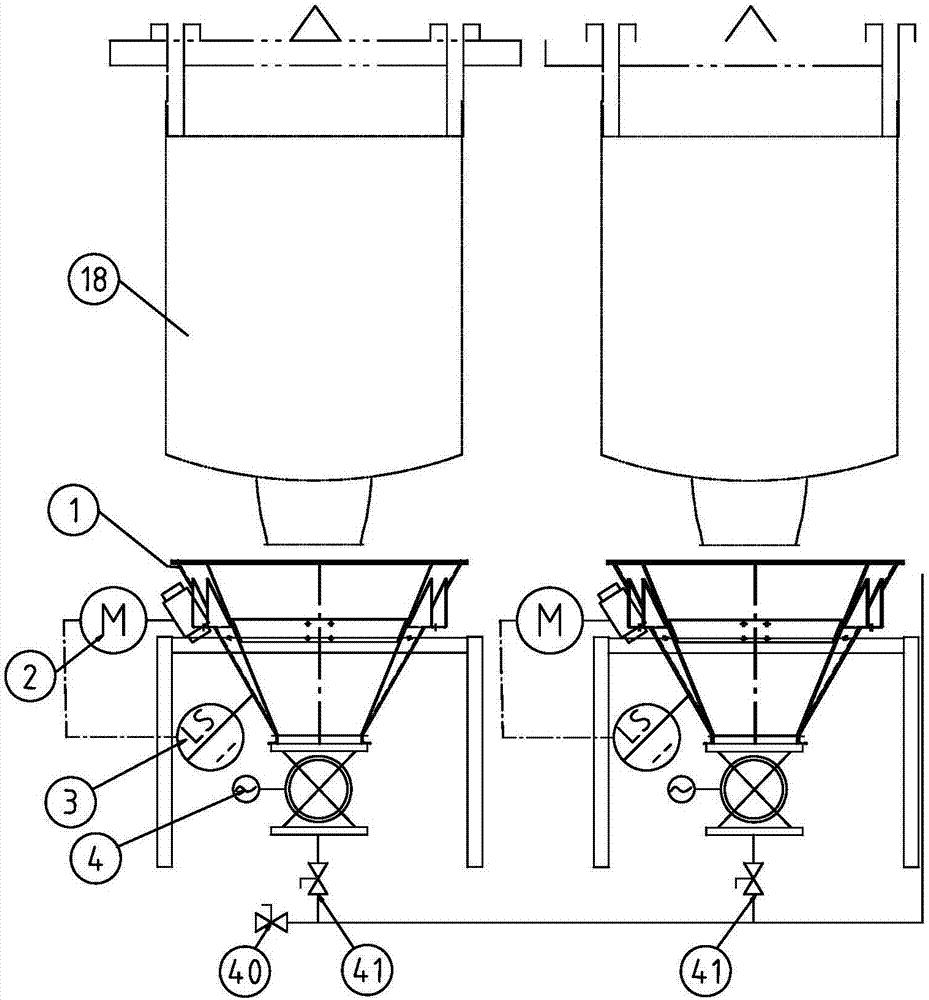

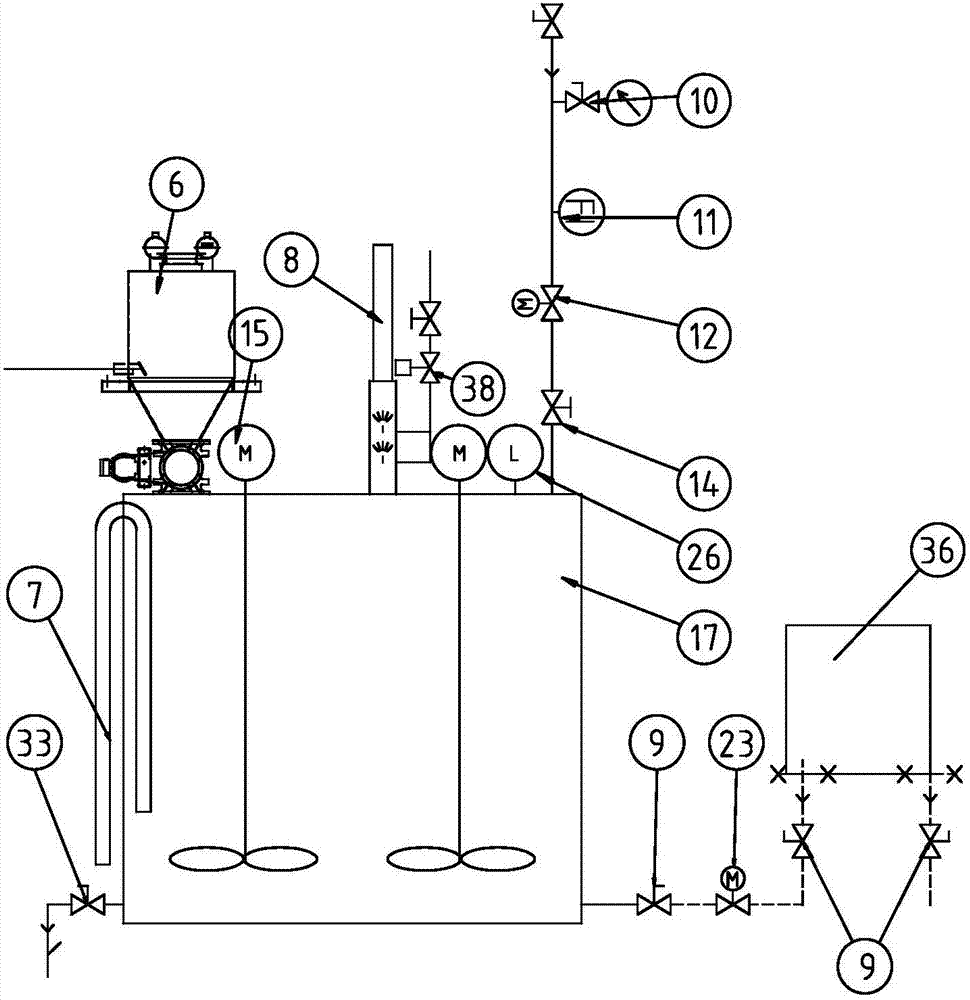

[0019] Such as Figure 1-Figure 5 As shown, a vacuum suction and feeding system with backwashing function includes a control cabinet 5, an air compressor 16, two sets of feeding mechanisms, two sets of conditioning devices 17, a dosing device 23 and a source water adding mechanism 19. One group of feeding mechanism corresponds to one group of conditioning devices 17, each group of feeding mechanism includes two ton bags 18, a bag breaker 1 is arranged under each ton bag, and a feeder 4 is arranged at the bottom of each bag breaker 1. The top of the conditioning device is provided with a powder conveyor 6 and a water control dedusting device 8. The bottom of the feeder 4 is connected to the powder conveyor 6 through a pipeline. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com