Rotor compressor and temperature regulating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0039] The invention describes a temperature regulating device, such as an air conditioner or a refrigerator, which includes a rotor compressor.

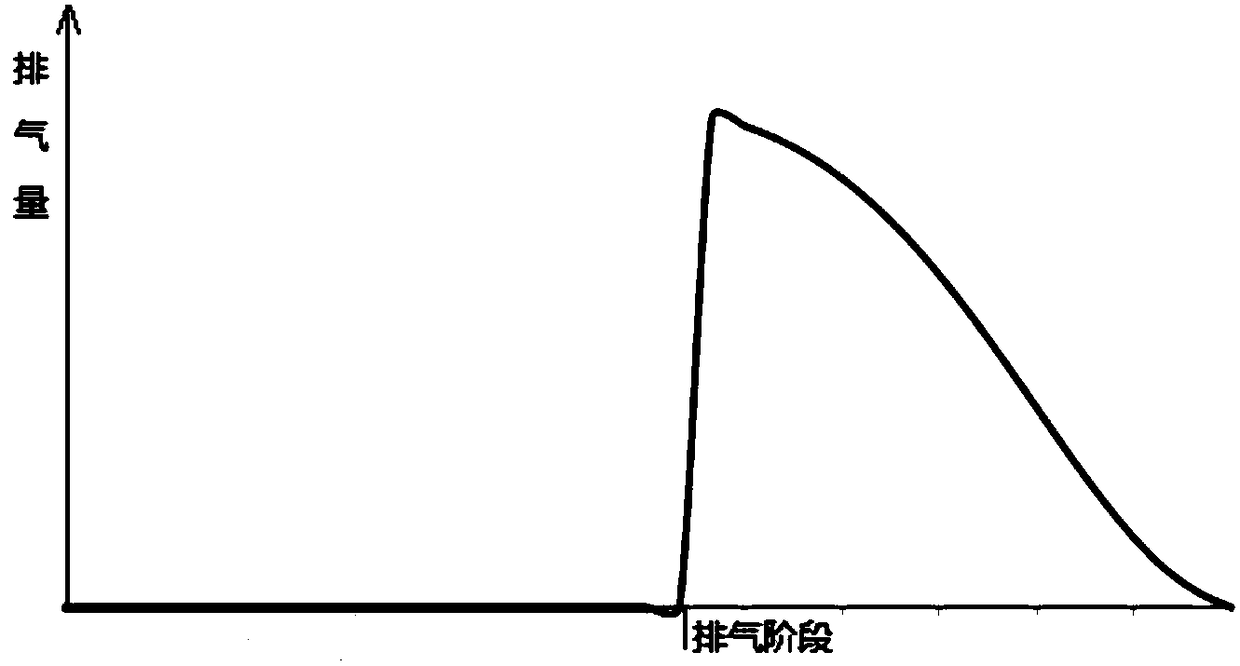

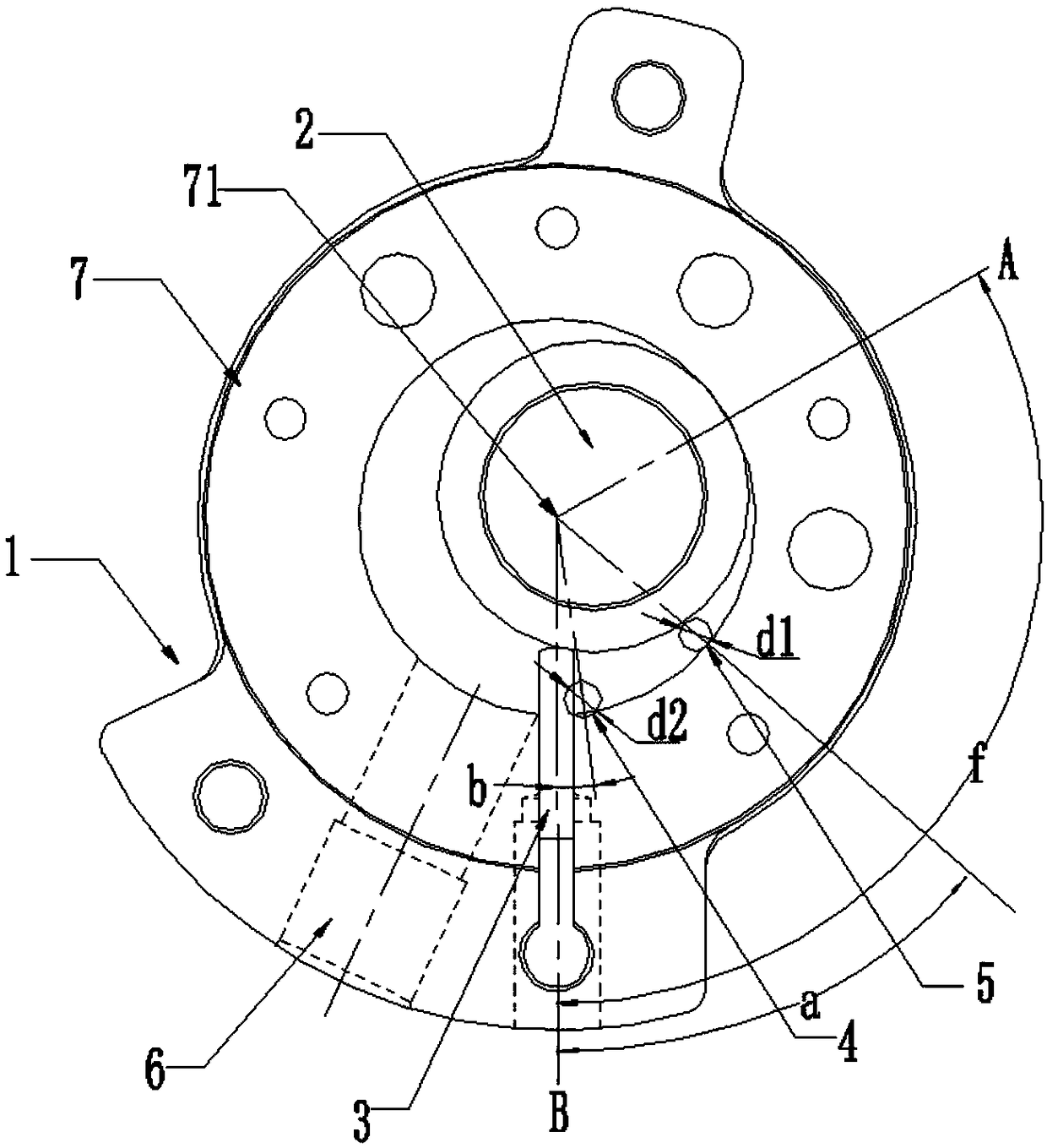

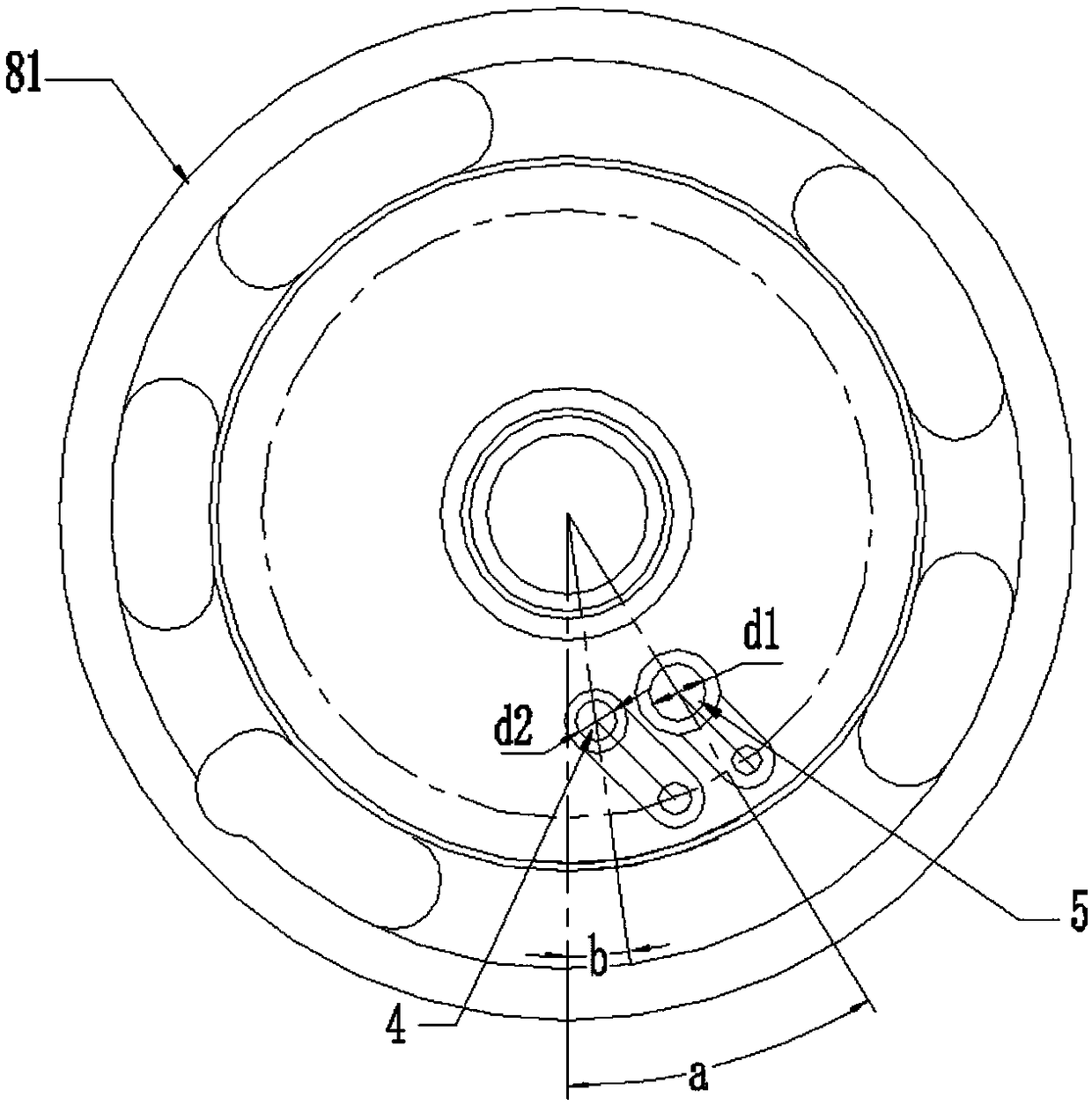

[0040] Such as figure 2 As shown, a rotary compressor of the present invention includes a pump body 1 , a rotor 2 and a sliding vane 3 . Among them, the pump body 1 is a cylindrical sealed cavity inside; the rotor 2 is a cam whose rotation center is coaxial with the cavity (that is, an eccentric rotor), and the cam and the cavity are always in tangential contact during rotation; the slide plate 3 Slidingly arranged on the pump body 1, it is always in contact with the rotor 2 under the action of the biasing force. The pump body 1 is also provided with a main exhaust port 4, an auxiliary exhaust port 5 and a suction port 6, wherein the main exhaust port 4 is arranged on the pump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com