Self-locking nut and installing method thereof

A self-locking nut, integrated technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of large axial force, cracking, inconvenient installation, etc., achieve large axial load, easy to manufacture, easy to install Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings.

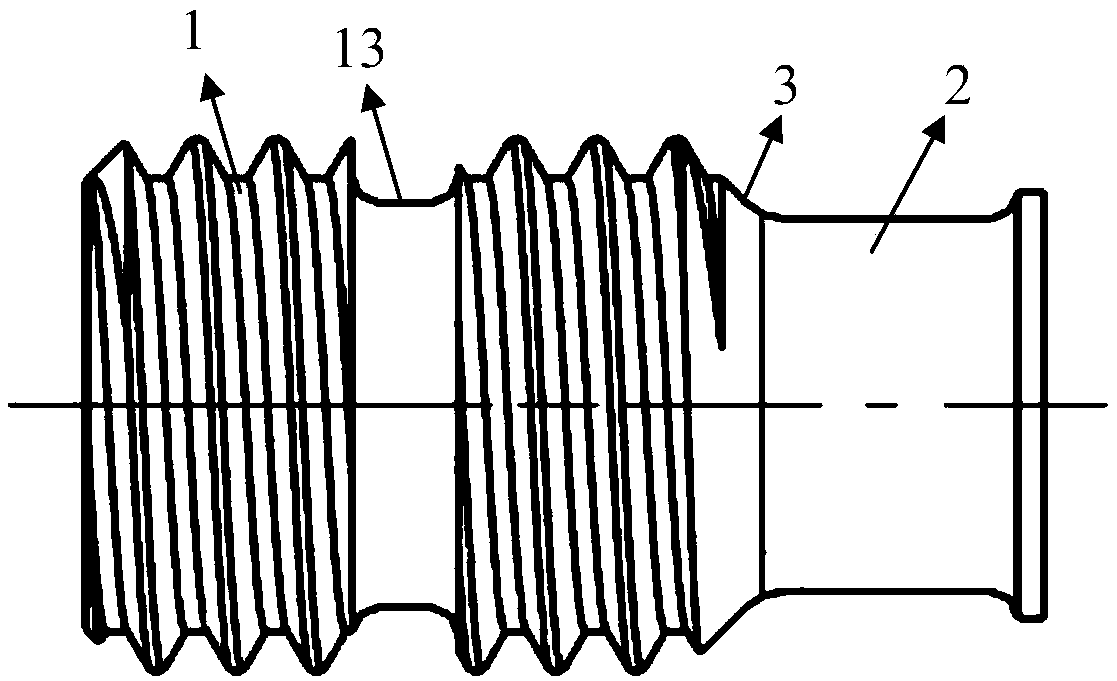

[0020] The self-locking nut provided by the invention, such as Figure 1-8 , including a main body part 1 and a riveting part 2 integrally connected in a ring shape, and an inner thread 11 is provided on the inner wall of the main body part 1 . Internal thread 11 is a functional part of design, and realizes the threaded connection that bolt 4 (can carry out screw thread cooperation with self-locking nut of the present invention by internal thread 11) installs, and internal thread 11 can be made common thread shape, also can Made into a reinforced thread shape. To facilitate the installation and disassembly of the bolt 4, the internal thread 11 is quenched to improve the strength of the thread. On the one hand, it can bear the large axial force from the bolt 4, and on the other hand, it realizes the single-sided connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com