A method for burning petrochemical waste liquid based on gas fuel

A petrochemical and gas fuel technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of petrochemical waste alkali environmental pollution, unreasonable gas fuel use ratio, high processing cost, etc., to avoid tail gas pollution and even The effect of turning off the engine to stop the problem, solving the energy waste and reducing the service life of the equipment, and reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

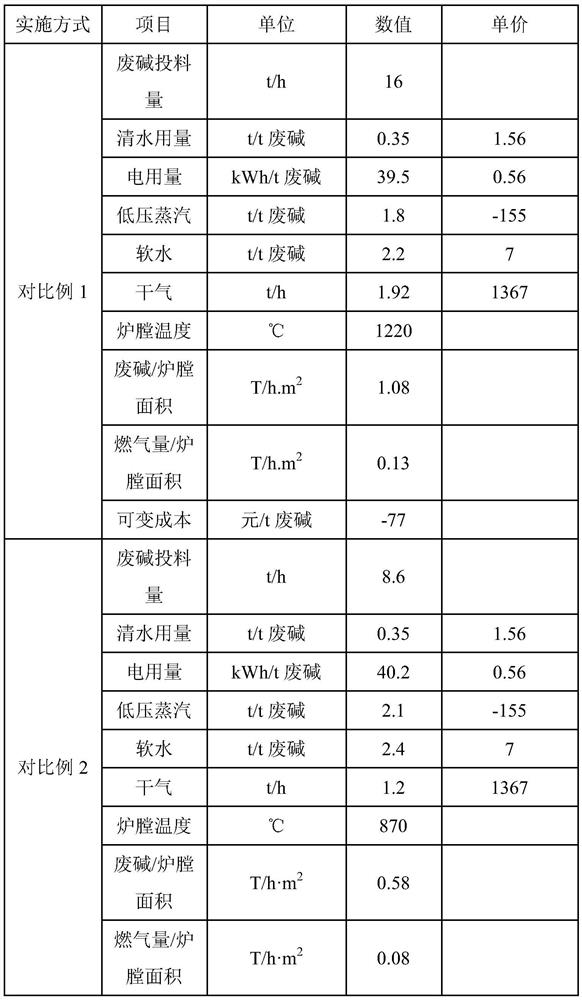

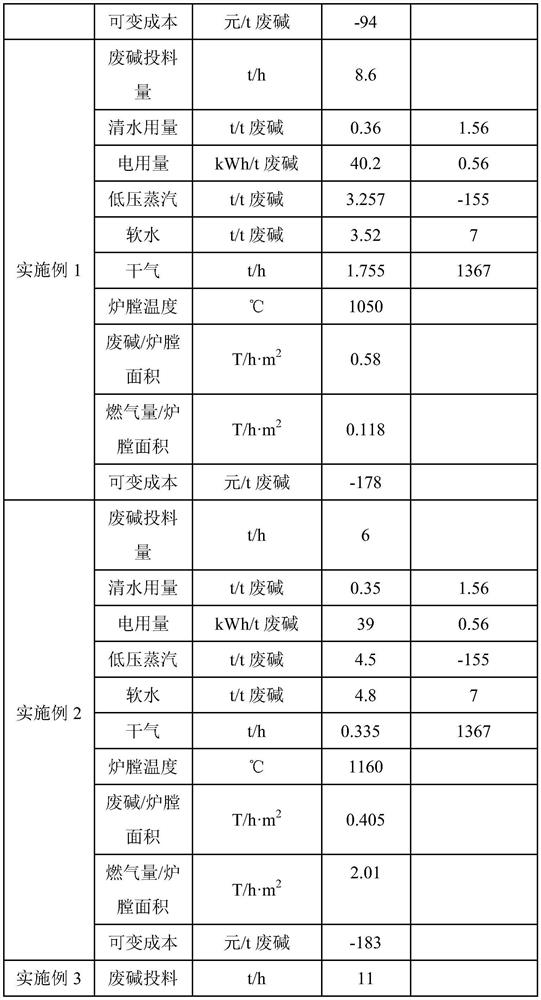

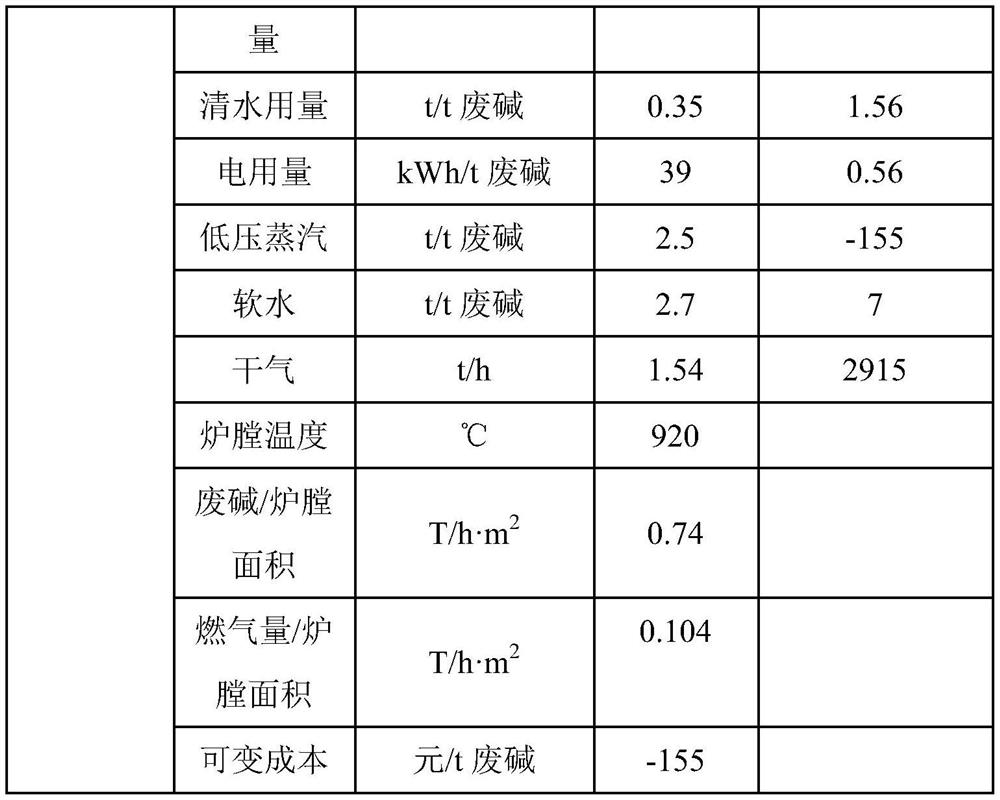

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the examples. If no specific conditions are indicated in the examples, it shall be carried out according to conventional conditions or conditions commonly used in the same industry.

[0021] A 100,000-ton cyclohexanone waste alkali incineration plant includes water-cooled walls, water-cooled screens, evaporation tube screens, steam drums, economizers, and air preheaters, etc. The square combustion chamber is composed of water-cooled walls with a size of 3.85m× 3.85 meters, the waste liquid incineration treatment process is as follows:

[0022] The saponified waste caustic liquor is pressurized to 1.8-2.5MPa and then sent to the saponified liquid spray gun, and after atomization, it enters the alkali recovery boiler, suspended and dried in the furnace, and burned in space (suspended combustion). The sodium salt of organic acid in the saponification liquid is converted into Na 2 CO...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap