A Method for Identifying Key Error Sources Affecting Accuracy Decay of Three-axis Machining Center

A machining center and identification method technology, applied in the direction of program control, instrument, computer control, etc., can solve the problems affecting the accuracy decay of three-axis machining center, the accuracy decay of three-axis machining center, etc., and achieve the effect of eliminating information overlap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

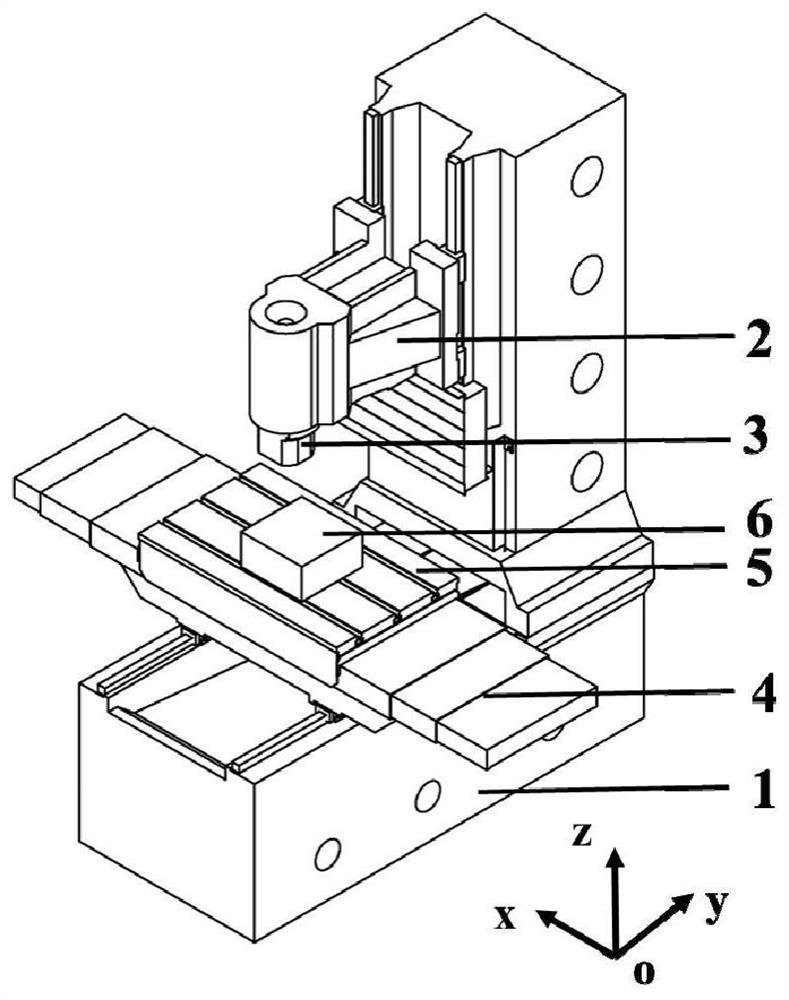

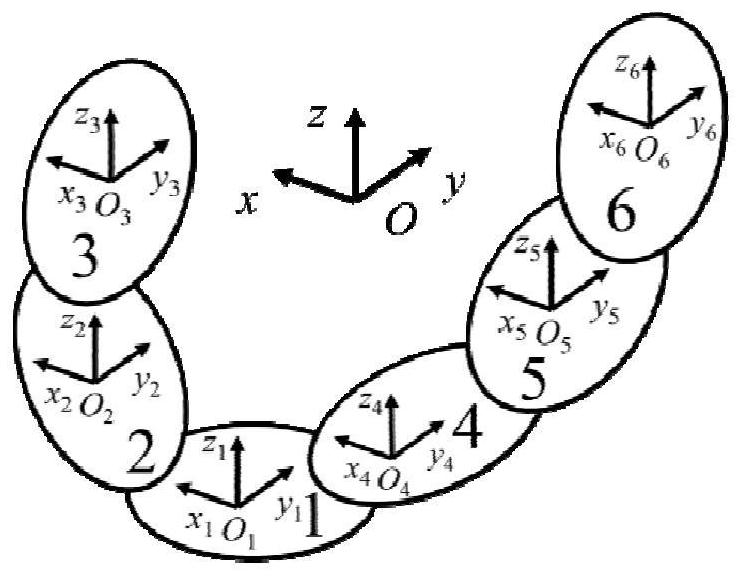

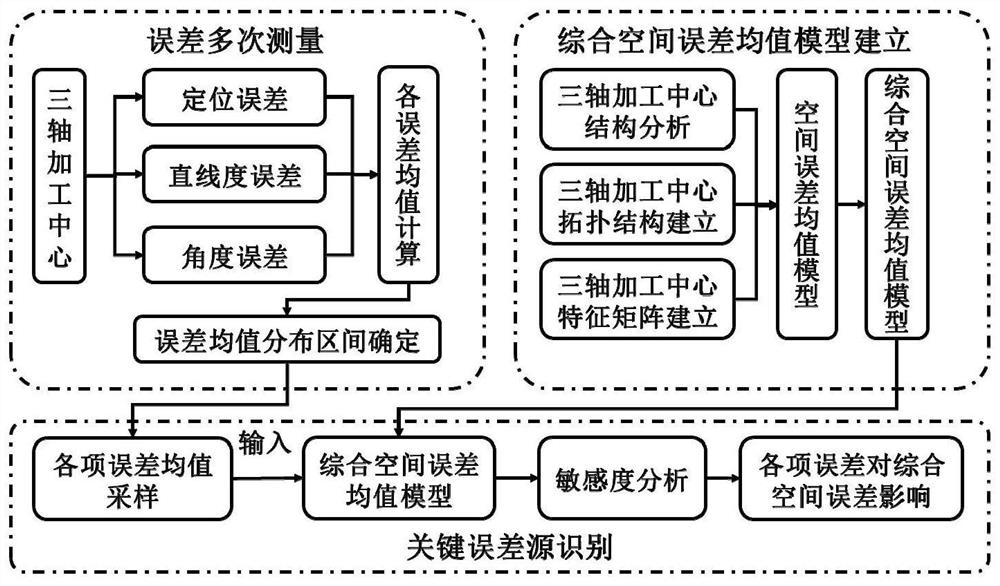

[0058] Example: A Method for Identifying Key Error Sources Affecting Accuracy Decay of a Three-axis Machining Center

[0059] Firstly, use the accuracy measuring device to obtain the error values of various accuracy of the machine tool at different measurement time nodes, calculate the error mean value of each accuracy item from the first measurement to each measurement time node, and determine the distribution interval of the error mean value of each accuracy; then, each The mean value of the error of each item is integrated at the tool forming point, and the mean value of the spatial distribution is integrated in the space dimension, and then the comprehensive spatial error mean value model of the three-axis machining center is established; finally, according to the distribution interval of the mean value of each error, the sensitivity analysis method is adopted , analyze the influence of the error mean value of each precision index in the interval on the comprehensive spat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com