Touch display substrate and its preparation method, repair method, touch display panel

A technology for touch display substrates and touch leads, which is applied in the fields of instruments, computing, and electrical digital data processing, etc., and can solve problems such as poor touch electrodes, dark touch leads and data lines, short circuits between touch leads and data lines, etc. problems, to achieve the effect of eliminating short circuit problems, eliminating dark line defects, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

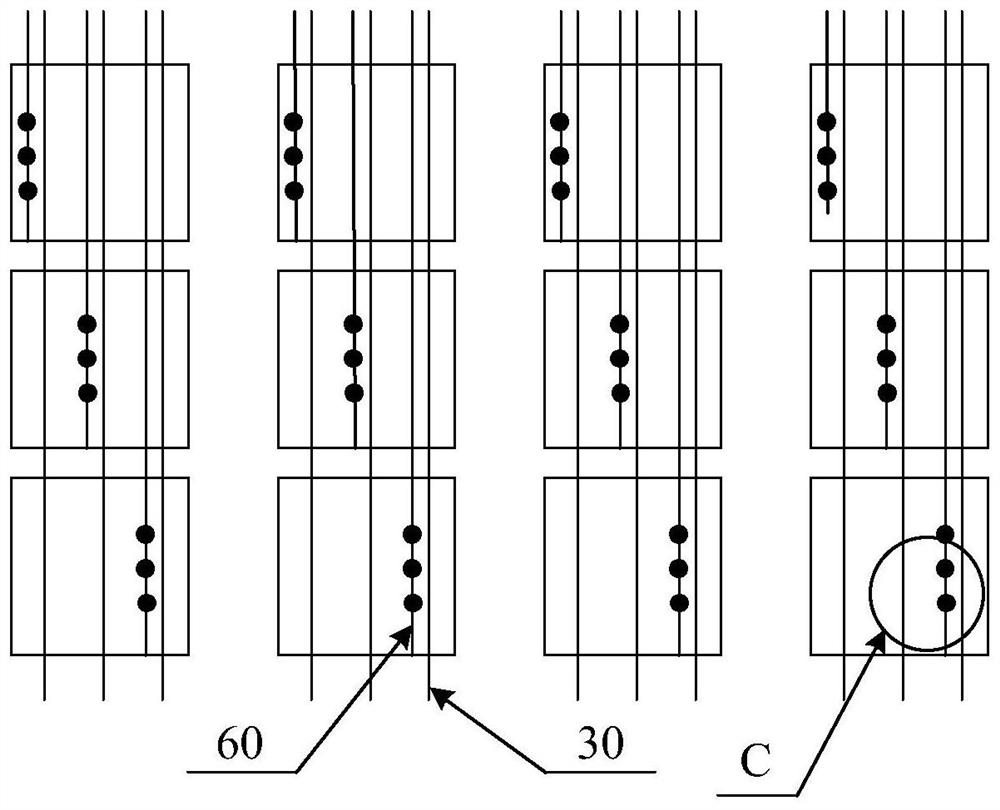

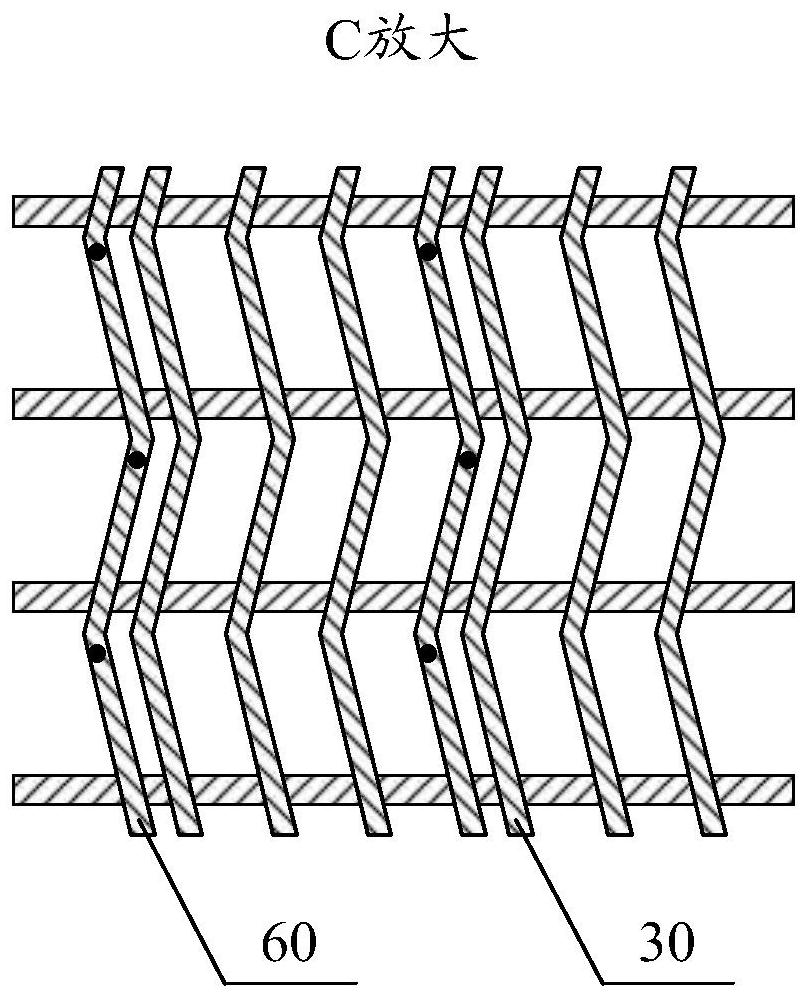

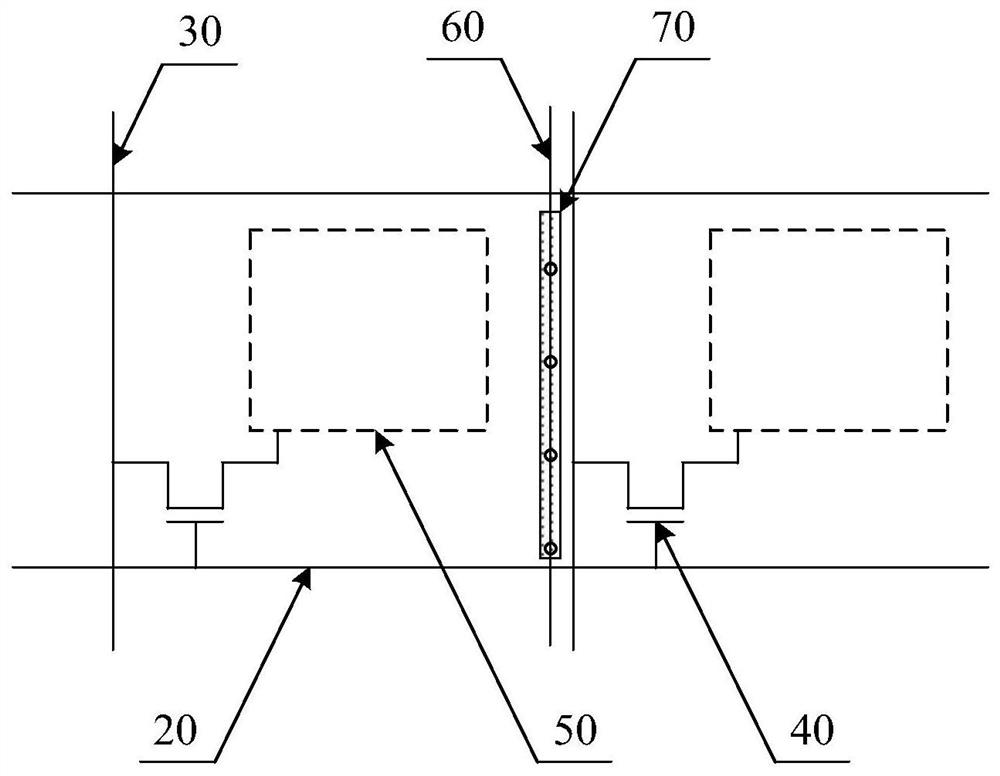

[0049] The main structure of the touch display substrate in this embodiment includes gate lines, data lines, thin film transistors, pixel electrodes, touch leads and connection lines. The gate lines and data lines vertically intersect to define several pixel units, and the thin film transistors and pixel electrodes are arranged on In each pixel unit, the touch wires are arranged between adjacent pixel units and connected to the touch electrodes. In this embodiment, the connection lines and the gate lines are arranged on the same layer and formed by the same patterning process, and a plurality of connection vias are opened on the first insulating layer covering the gate lines and the connection lines, and the touch leads pass through the plurality of connection vias. The hole is connected with the connecting wire.

[0050] The technical solution of this embodiment will be further described below through the preparation process of the touch display substrate.

[0051] Figure ...

no. 2 example

[0071] The main structure of the touch display substrate in this embodiment is the same as that of the aforementioned first embodiment, including gate lines, data lines, thin film transistors, pixel electrodes, touch leads and connection lines, and the gate lines and data lines vertically intersect to define several pixel units , the thin film transistor and the pixel electrode are arranged in each pixel unit, and the touch lead is arranged between adjacent pixel units and connected with the touch electrode. Different from the bottom gate structure in the first embodiment, the embodiment of the present application is a top gate structure.

[0072] The manufacturing process of the touch display substrate in this embodiment includes: firstly, a shielding layer and an active layer pattern are formed on the substrate through a patterning process. Subsequently, a first insulating layer is deposited, and patterns of gate electrodes, gate lines and connecting lines are formed on the ...

no. 3 example

[0083] Based on the technical concept of the present invention, the technical solutions of the foregoing embodiments can also be expanded in various aspects. As an implementation solution, the connecting wires may be arranged in other film layers, not necessarily in the same layer as the grid lines, for example, may be arranged in the same layer as the shielding layer. As another implementation solution, the connection wires can be arranged in the film layer above the touch lead wires and data lines, that is, the connection wires are arranged in a film layer far away from the base relative to the film layer where the touch lead wires and data lines are located. Touch leads can be cut from the backside of the substrate. As yet another implementation solution, the connecting wires can be separately arranged in one film layer and prepared through a single patterning process. Other extensions The present invention is not specifically limited here, and the above extensions can eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com