Integrated basic practical training platform for industrial robot

An industrial robot and training platform technology, applied in the field of teaching and training platform, can solve the problems of scattered teaching, limited teaching activities, unable to form an organic combination, etc., and achieve the effect of solving scattered and non-uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

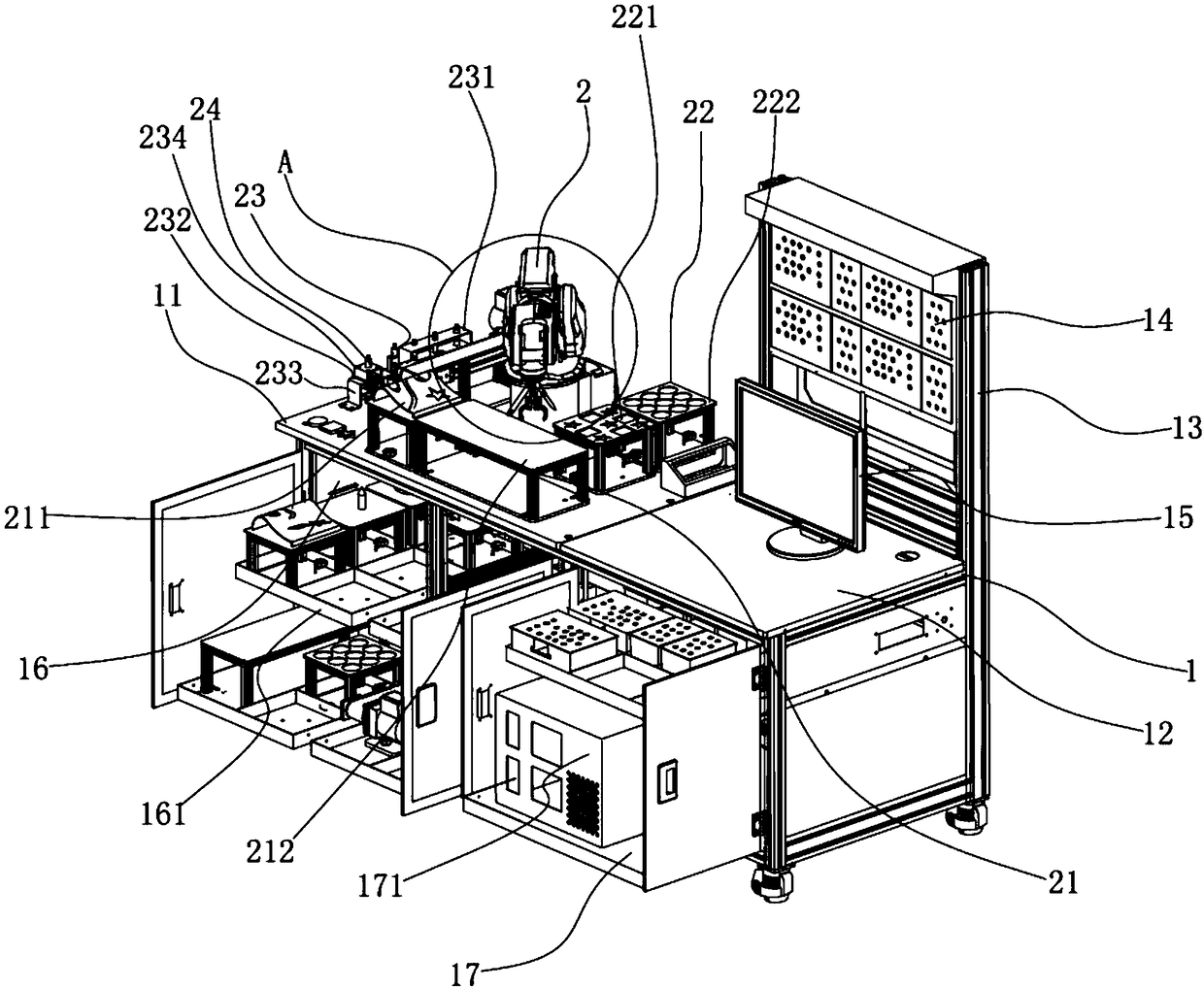

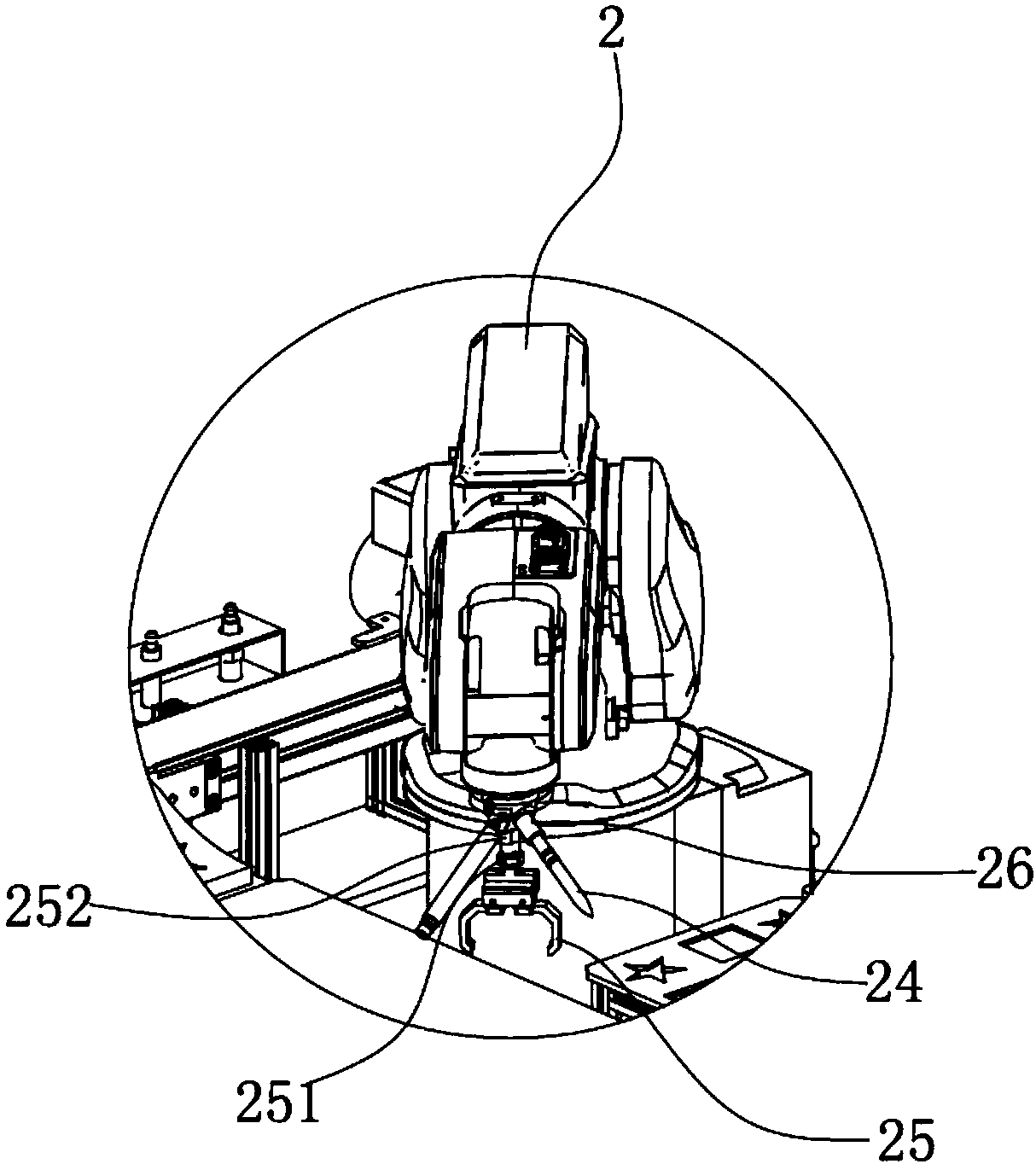

[0021] see Figure 1 to Figure 2 , the figure shows an industrial robot integration basic training platform provided by Embodiment 1 of the present invention, which includes a machine platform 1, and the machine platform 1 is provided with an adjacent first area 11 and a second area 12, the second A display 15 is installed on the area 12 to realize the display function of the operation. The multi-axis manipulator 2 is arranged on the first area 11, and the first module support 21, the second module support 22 and the tool are respectively arranged around the multi-axis manipulator 2. Support 23, a plurality of first modules 211 are placed on the first module support 21, a plurality of second modules 221 are placed on the second module support 22, a plurality of tools 24 are placed on the tool support 23, and the tool 24 and the multi-axis machine The arm 2 is detachably connected, and a clamping part 25 is installed on the multi-axis mechanical arm 2, and the clamping part 25 ...

Embodiment 2

[0025] see Figure 1 to Figure 2 , the figure shows an industrial robot integration basic training platform provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the first module bracket 21. The second module support 22 and the tool support 23 are distributed in a U shape. Through the improvement of the above structure, the overall arrangement can be made more compact, thereby saving more installation space.

Embodiment 3

[0027] see Figure 1 to Figure 2 , the figure shows an industrial robot integration basic training platform provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the first module bracket 21 includes a plurality of first module support units 212, the first module support unit 212 is a U-shaped support; the second module support 22 includes a plurality of second module support units 222, and the second module support unit 222 is a U-shaped support. Through the improvement of the above structure, it is convenient to place each training module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com