Dust removal mechanism for electrical cabinet

A technology for electrical cabinets and dust collectors, which is applied to the cooling/ventilation of electrical components, substations/switchgear, substations/power distribution equipment shells, etc. It can solve the problems of slow dust collection rate, long cycle, and slow cleaning rate. Efficient dust collection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

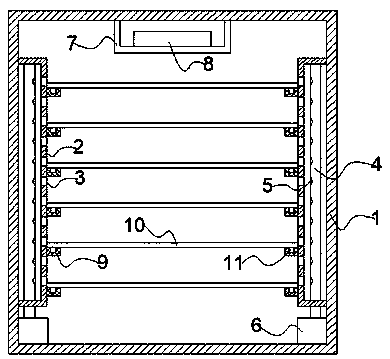

[0012] like figure 1 As shown, the present invention discloses a dust removal mechanism for an electrical cabinet, including an electrical cabinet body 1, a U-shaped connecting plate 2, a ventilation hole 3, an air duct 4, an air outlet 5, a blower 6, a connection box 7, and a dust remover. 8. U-shaped connecting plates 2 are fixedly installed on the inner walls of the left and right sides of the electrical cabinet 1, and the U-shaped connecting plates 2 are clamped on the inner wall of the electrical cabinet 1 in an inverted manner. An air duct 4 is installed in the clamping groove of the shaped connecting plate 2 and the electrical cabinet 1, and a plurality of blowing ports 5 are opened on the side wall of the air duct 4, and a plurality of the blowing ports 5 are arranged along the wind. The vertical pipe wall of the pipe 4 is opened, and the bottom plate of the U-shaped connecting plate 2 is provided with a ventilation hole 3 which is arranged opposite to the air outlet 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com