Stepping motor driving device and stepping motor driving method

A technology of stepping motors and driving devices, which is applied in the direction of motor generator control, electrical components, control systems, etc., can solve problems such as difficulty in adjustment, time-consuming, and limitations in the improvement of indexing feed performance, and achieve suppression of heat generation and vibration high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

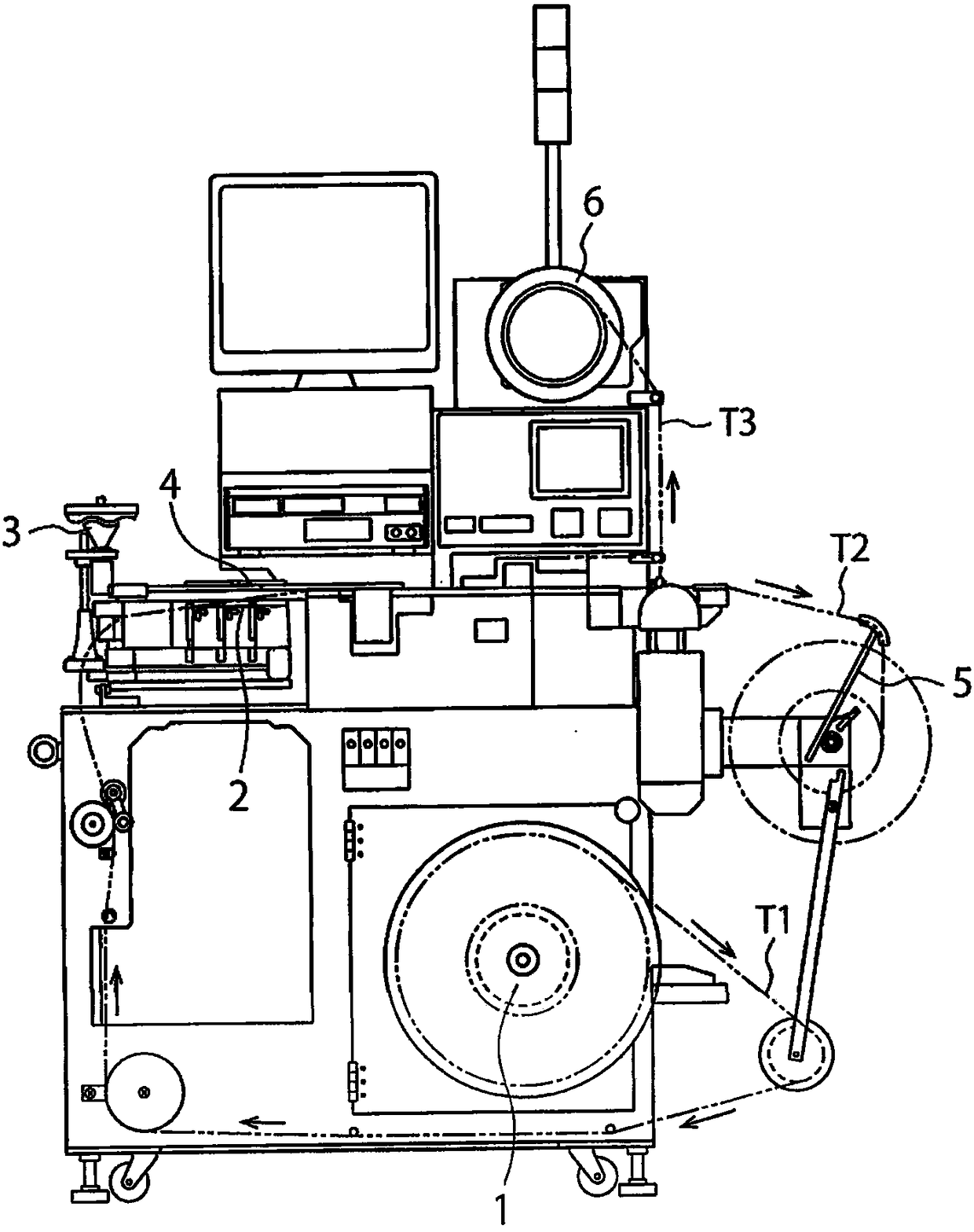

[0035] figure 1 It is a front view showing the structure of the tape tie machine of 1st Embodiment.

[0036] figure 1 The tape machine adopts indexing method, including tape supply reel holding part 1, indexing table 2, parts feeder 3, soldering iron part 4, finished tape holding part 5 and top tape reel holding part 6. figure 1 The tape machine is used for tape of chip electronic components such as capacitors.

[0037] The tape machine conveys the tape T1 from the tape supply reel holding unit 1 via the index table 2 , and conveys the parts from the parts feeder 3 . Components from the component feeder 3 are welded to the tape T1 from the index table 2 by the soldering iron unit 4 . Then, the finished tape T2 obtained from the tape T1 is sent to the finished tape holding section 5 , and the top tape T3 remaining on the tape T1 is sent to the top tape reel holding section 6 .

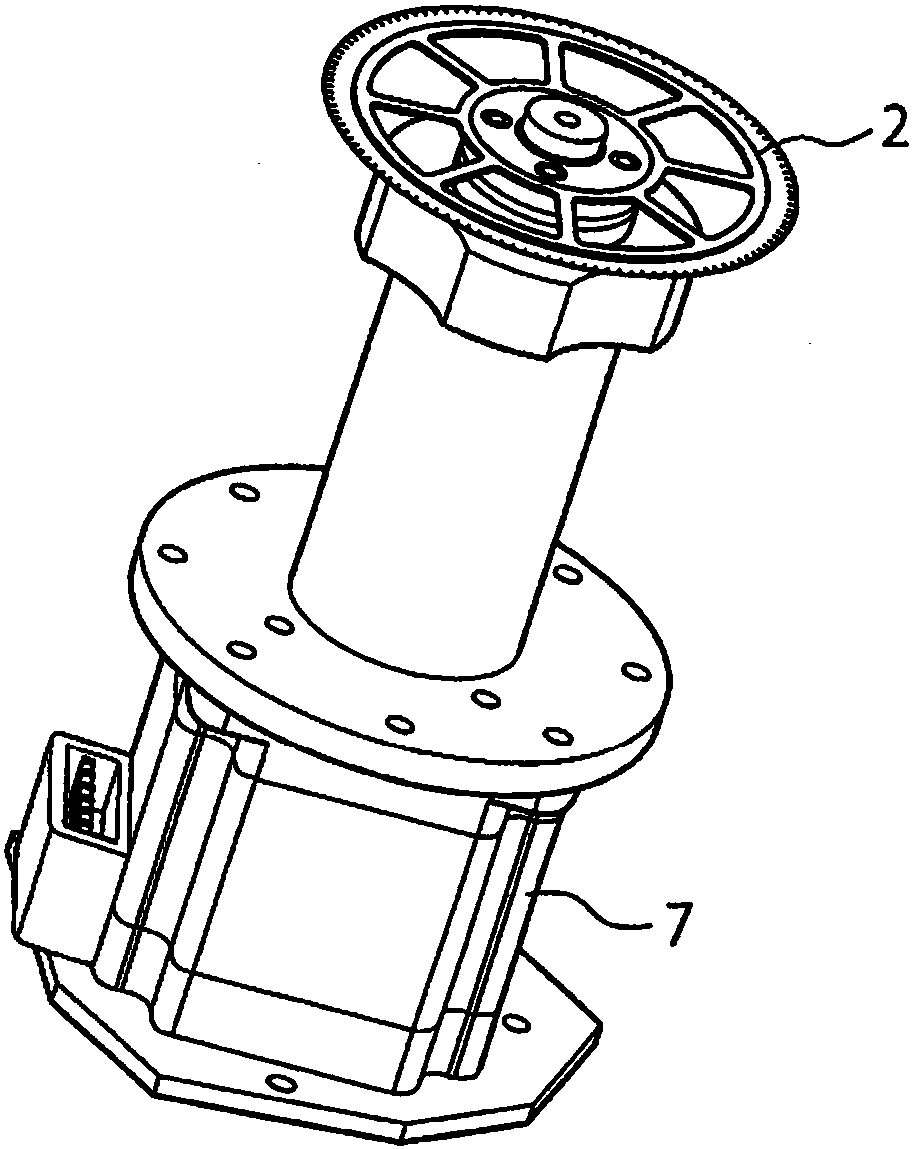

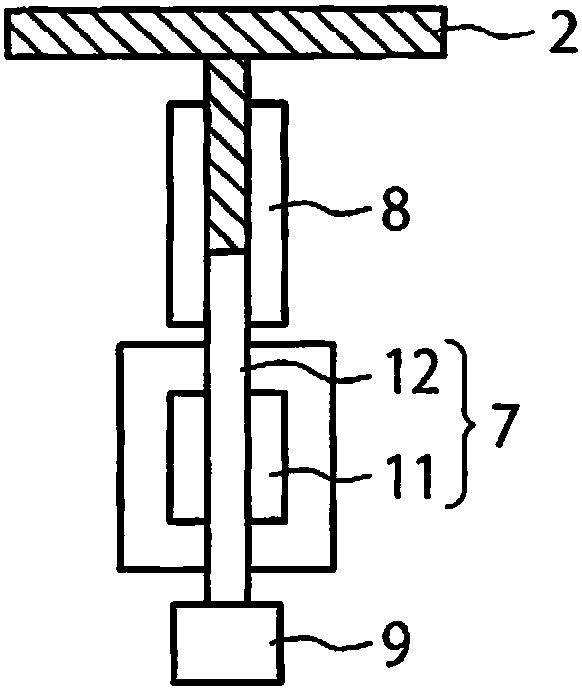

[0038] figure 2 It is a perspective view which shows the structure of the index table 2 etc. w...

no. 2 Embodiment approach

[0096] Figure 12 It is a graph showing temporal changes of the first current IA and the second current IB in the second embodiment. In this embodiment, differences from the first embodiment will be mainly described, and a detailed description of the points common to the first embodiment will be omitted.

[0097] In the first embodiment, the first and second coils 13A and 13B are driven by two-phase excitation, but in this embodiment, the first and second coils 13A and 13B are driven by one-phase excitation.

[0098] exist Figure 12 Among them, the first current IA changes to the first value I1, the third value I3, and zero, and the second current IB changes to the second value I2, the fourth value I4, and zero. Here, the first value I1 and the fourth value I4 are positive values, and the second value I2 and third value I3 are negative values. However, the absolute value of the second value I2 and the absolute value of the fourth value I4 are set smaller than the absolute ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap