Beam receiving device for tail end of proton beam line

A technology for receiving devices and proton beams, applied in accelerators, electrical components, magnetic resonance accelerators, etc., can solve problems such as difficult and precise positioning, achieve the effects of improving success rate, avoiding random errors, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] In fact, the beam receiving device for the end of the proton beam line provided by the present invention is an irradiation experiment device, which is usually set at the end of the proton beam line and used to receive part of the proton beam for irradiation experiments , and at the same time block the redundant proton beam. In order to facilitate the installation of the beam receiving device of the present invention, a counterbore should be provided at the end of the proton beam line in advance.

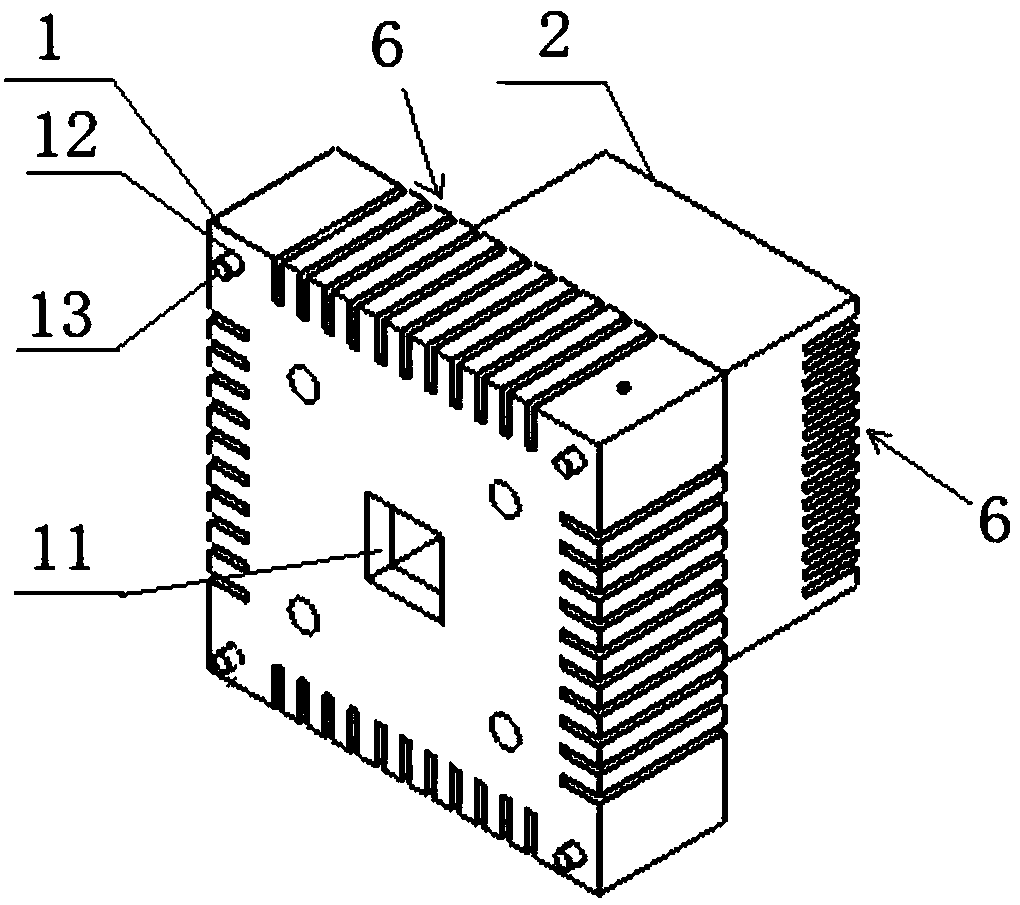

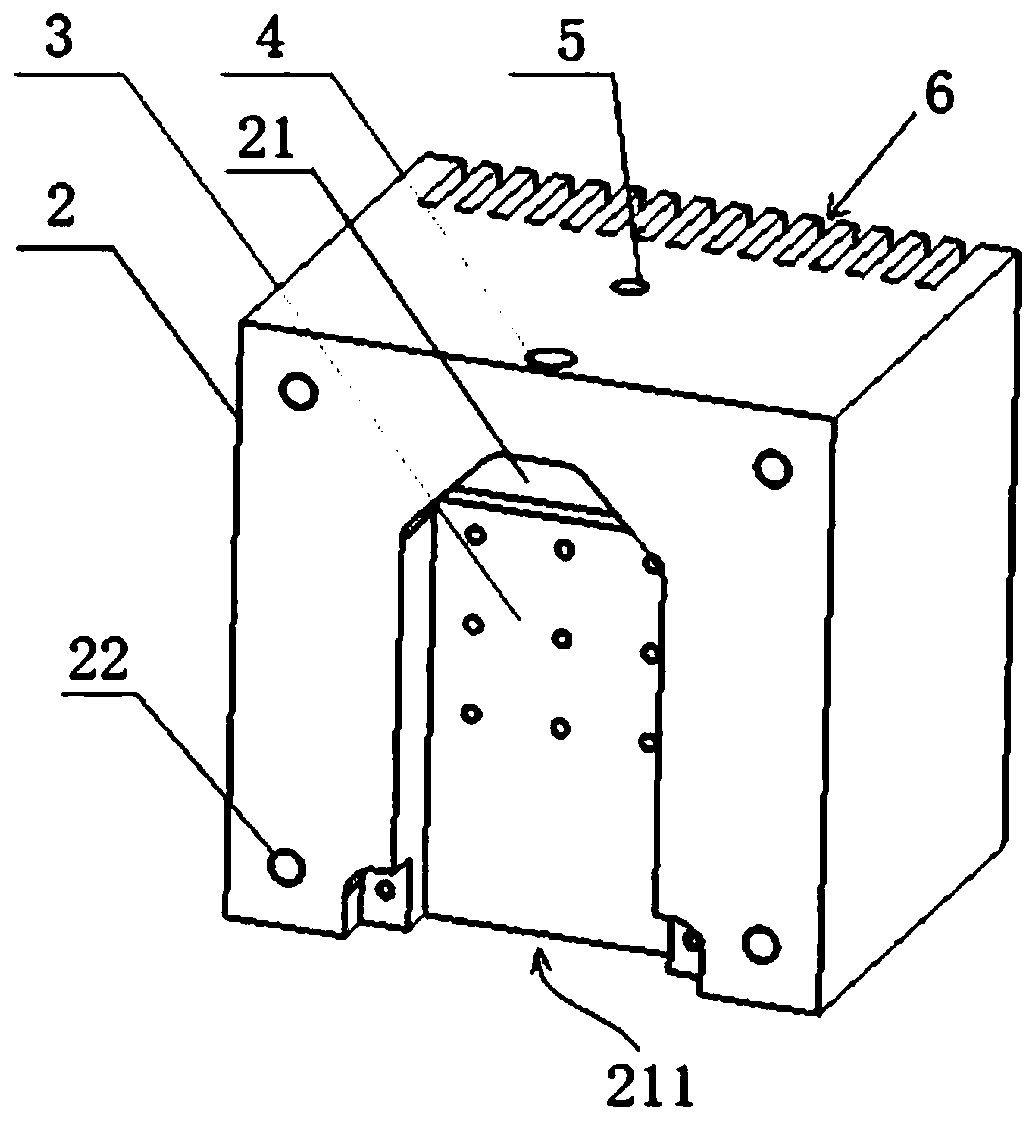

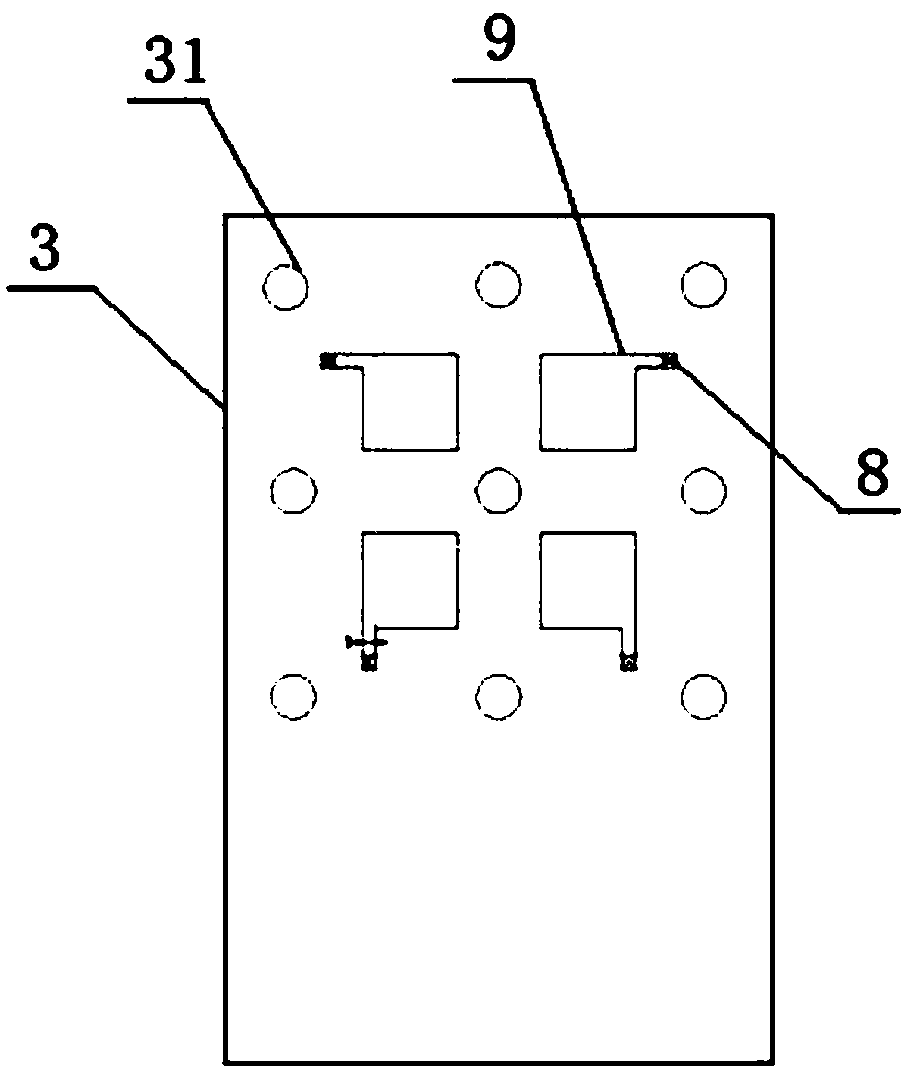

[0029] Such as figure 1 As shown, a kind of beam receiving device for the proton beam line end provided by the present invention comprises a beam introduction plate 1 for being connected to the coaxial insulating connection of the counterbore hole at the end of the proton beam line, and a beam introduction plate 1 The board 1 is coaxially insulated to a bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com